R&D

Impacts

Energy innovation starts here

INL’s energy mission has always involved testing materials and defining parameters to safely operate reactors. Beyond nuclear, the lab’s mission encompasses energy sources such as wind, hydro and bioenergy, electric vehicles, battery performance, and low-carbon production of fuels, advanced materials, and hydrogen. High-performance computing supports efforts in advanced modeling and simulation. The lab is a leading resource for cybersecurity and infrastructure and grid resilience.

Accomplishments and data are from fiscal year 2024.

Nuclear Energy

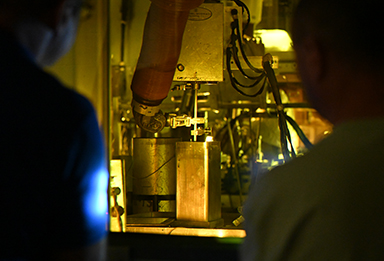

New hot cell facility built at INL, the first in 49 years

The Sample Preparation Laboratory at INL’s Materials and Fuels Complex completed major construction milestones and is officially ready to begin installing advanced scientific instruments. SPL is the first hot cell facility built at INL in nearly 50 years. Its unique materials analysis capabilities and flexible design will enable research that can extend the lives of current reactors while supporting the development of new advanced reactors.

Next-generation nuclear fuel arrives at INL for testing

For the first time in two decades, INL received experimental nuclear fuel rods irradiated in a commercial nuclear power plant to study on-site. The fuel rod technology could save electricity rate payers millions of dollars per year while increasing a nuclear power plant’s resilience under potential accident conditions. But first, INL researchers must subject the fuel rods to several years’ worth of examinations and experiments to prove their performance and safety.

First MARVEL reactor component fabrication completed

The Microreactor Applications Research Validation and Evaluation (MARVEL) microreactor project completed its first component fabrication – the reactor guard vessel. Carolina Fabricators Inc., produced this first large component, completing fabrication in September 2024. When operational, MARVEL will produce roughly 85 kilowatts of heat while helping researchers and engineers better understand how to build and operate a new reactor design and offering private sector companies a testing platform.

Broke ground on Project Pele

The U.S. Department of Defense broke ground in September on the Project Pele transportable nuclear reactor. The reactor is being manufactured by BWXT Advanced Technologies in Lynchburg, Virginia, with final assembly set for February 2025. The schedule calls for the fully assembled reactor to be shipped to INL in 2026 for testing.

Top influencers tour INL facilities

As public interest in nuclear energy grows, INL continued to welcome high-profile science and climate influencers to tour its key facilities. Recent visitors have included Miss America 2023 Grace Stanke, Isabella Boemeke, Madi Hilly, Sierra Quitquit, Michael Mezzatesta and Kyle Hill. In a rapidly changing media environment, these influencers on such platforms as YouTube, Instagram, X and TikTok are gaining recognition as an effective way to shape public opinion.

Microreactor experiment test bed, demos hit milestones

Construction has started on the National Reactor Innovation Center’s Demonstration of Microreactor Experiments (DOME) test bed and is planned to be complete as soon as 2026. Located at INL’s Materials and Fuels Complex, the NRIC-DOME will host fueled experiments producing up to 20 megawatts of energy. Microreactor experiments planned for demonstration in the NRIC-DOME include concepts from Westinghouse and Radiant Industries, both of which completed their front-end engineering and experimental design phase in 2024.

National & Homeland Security

Staff member testifies about cybersecurity for water facilities

INL staff member Virgina Wright testified before the U.S. Senate’s Water and Power Subcommittee on cyber threats to critical water infrastructure and how cyber-informed engineering – developed by INL – can be leveraged to secure the nation’s dams, reservoirs and hydropower plants. Witnesses at the hearing and subcommittee chairman Sen. Ron Wyden, D-OR, commented on how CIE might help protect water infrastructure, especially smaller and more remote dams and power plants.

Lab teaches radiological response techniques

INL led a radiological response training workshop in Cavtat, Croatia, teaching emergency responders from Croatia, Italy and Poland to assess risks, coordinate emergency actions, and mitigate the consequences of radiological incidents and accidents. The training was conducted in parallel with the Chemical, Biological, Radiological, Nuclear, and Explosives Science and Consequence Management World Congress. The course offered participants hands-on experience and in-depth insights into the complexities of radiological incident management.

Wireless Test Bed marks 20 years

In June, INL celebrated the 20th anniversary of its Wireless Test Bed, which is recognized as the premier wireless research and development facility of its kind in the United States. Since 2004, it has grown to become a large-scale, open-air controlled range that includes full-scale communications networks that enable testing of wireless systems and equipment ranging from high frequency, ultrahigh frequency, cellular, satellite, microwave and everything in between.

White House recognizes INL’s cybersecurity work

INL’s efforts at securing operational technology got a shoutout from the White House following a G7 Leaders’ Summit in June. The lab has been active in establishing a new cybersecurity framework for technologies used in electricity, oil and natural gas facilities. National Security Advisor Jake Sullivan’s statement noted that the work done at INL has “brought tremendous expertise to bear in securing operational technologies to date.”

TRIPWIRE wins R&D 100 award

TRIPWIRE, a radiation monitoring system developed at INL, received a 2024 R&D 100 Award. For over 62 years the R&D 100 Awards have celebrated technology innovations in the private and public sectors. TRIPWIRE uses thin scintillating fibers to detect radiation over large, remote areas such as nuclear material repositories. Connected to above-ground electronics, the fibers detect changes in radiation and provide early notice of any radioactivity presence or release.

Air Force Fellows learn new cyber skills

Two Air Force Fellows, Lt. Col. Kurando “Claude” Mensen and Maj. Rachel E. Donoho, spent 10 months at INL learning about cybersecurity and Consequence-driven Cyber-informed Engineering, a methodology developed at INL to address threats to the nation’s critical infrastructure systems. The Fellows program advances national security proficiencies in U.S. Air Force and Space Force leaders. INL’s participation in the program dates back to 2010.

Analyses drive security investments in Pacific

INL critical infrastructure analyses of two U.S. Pacific territories is guiding senior government and military officials as they decide security investments in areas of strategic importance. Sponsored by the Cybersecurity and Infrastructure Security Agency, the INL analyses included recommendations for investments in two harbors in Rota Island in the Commonwealth of the Northern Mariana Islands, to serve as alternate ports in case of an emergency at Guam’s Apra Harbor, one of the U.S. Navy’s most important Pacific deep-water ports.

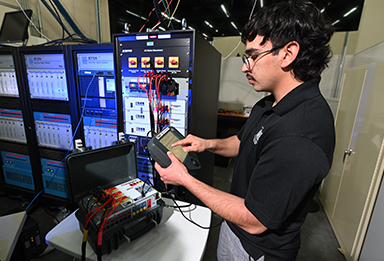

Lab finds, provides fixes for critical cyber flaws

Testing industrial control system components under DOE’s CyTRICS program, INL researchers uncovered critical vulnerabilities in several vendors’ products and helped them mitigate and resolve the issues. They identified multiple vulnerabilities in GE Vernova’s universal controller and helped Hitachi Energy find a critical flaw in its Tropos mesh router. Additionally, the Department of Homeland Security’s Cybersecurity and Infrastructure Security Agency issued an advisory based on INL’s discovery of a denial-of-service vulnerability in AVEVA’s SuiteLink Server equipment.

Energy & Environment

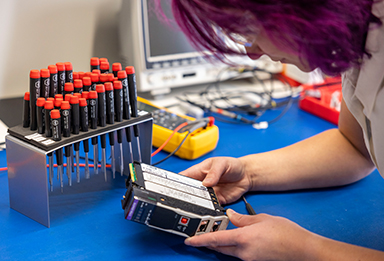

ChargeX Consortium releases recommendations

The INL-led ChargeX Consortium released recommendations in 2024 designed to improve electric vehicle owners’ charging experience. In a 2024 report, the consortium defined a basis for common performance targets for EV charging at public stations, where drivers sometimes encounter equipment reliability problems. The recommendations will help the industry measure drivers’ experience and provide a uniform set of metrics for quantifying the charging experience from a customer perspective.

Construction begins at the Energy Technology Proving Ground

Work is progressing on INL’s Energy Technology Proving Ground, a test complex designed to advance the commercialization of new clean energy technologies. Situated at the Central Facilities Area, the proving ground offers comprehensive and impartial testing and validation of various energy systems. One of the first technologies to undergo testing will be high-temperature electrolysis for hydrogen production, in collaboration with industry partners.

Solving recycling challenges

Pizza is a $47 billion-a-year business in the United States and roughly one-third of those pies come in corrugated cardboard boxes. Unlike many food containers, those boxes can’t be recycled due to the cheese and grease residue, but the Journal of Cleaner Production published INL research showing how to use material separation capabilities to decontaminate pizza boxes.

Turning ocean plastics into valuable fuels

The Ocean Plastics Recovery Project (OPRP) partnered with INL’s Biomass Feedstock National User Facility (BFNUF) in its research to convert plastic waste into useful fuels and chemicals. A user facility agreement allows the OPRP to process collected plastics using BFNUF’s equipment and available biomass resources. As a part of this effort, researchers gained valuable insights into turning ocean plastics into a useable feedstock.

Previous R&D Impacts

Not finding what you are looking for? Please send your question to [email protected].