Idaho National Laboratory hosted a three-day meeting the first week of May on Accident Tolerant Fuels (ATF), the government-backed effort to develop safer fuels for nuclear reactors.

Nuclear Regulatory Commission staffers and others involved in ATF development saw the lab’s testing capabilities, in particular the Advanced Test Reactor (ATR) and newly recommissioned Transient Reactor Test (TREAT) facility. At an NRC briefing on ATF in April, Bill McCaughey, acting director of the U.S. Department of Energy’s Advanced Fuels Technologies program, hailed TREAT’s refurbishment as “probably the most significant addition” to the ATF effort.

After the Fukushima Dai-ichi disaster of March 2011, Congress ordered DOE to give priority to the development of meltdown-resistant fuels and cladding for light water reactors. Although it may be impossible to develop nuclear fuel that is 100 percent accident proof, the idea is that accident tolerant fuels will give operators more time to respond to an event and minimize reactor damage.

At Fukushima, the greatest damage occurred after the tsunami breached the plant’s sea wall and knocked out emergency diesel generators supplying power to the plant’s pumps and cooling system. The insufficient cooling led to three nuclear meltdowns, hydrogen-air explosions, and the release of radioactive materials.

Three companies responded to the DOE call — General Electric, Westinghouse and Areva – and formed a consortium with other companies to develop advanced fuel concepts.

The program reached an important milestone March 4, as ATF assemblies went live at Southern Nuclear’s Edwin I. Hatch Plant near Baxley, Georgia. Between now and 2020, Hatch Unit 1, a 1975-built General Electric (GE) boiling water reactor rated at 924 megawatts, will test iron-chromium-aluminum fuel cladding material known as “IronClad” and coated zirconium fuel cladding known as “ARMOR.”

Both Areva and Westinghouse are planning to test rods in 2019 at plants in Illinois: the LaSalle County Nuclear Generating Station (Areva) and Exelon’s Byron Generating Station (Westinghouse). “The vendor teams have actually all gotten quite excited,” said INL’s Steven Hayes, national technical director of the Advanced Fuels Campaign. “All these teams have plans to get test fuel or cladding in place.”

DOE adopted a three-phase approach to ATF development and commercialization. Phase 1, which ended in 2016, included feasibility assessments, during which fuel concepts were developed, tested and evaluated. These included laboratory-scale experiments such as preliminary irradiation, material properties measurements, and assessment of economic, operational, safety, fuel cycle and environmental impacts. The cladding assemblies installed in March at Hatch No. 1 were made at DOE’s Oak Ridge National Laboratory. Additional irradiations at ATR are planned for later this year.

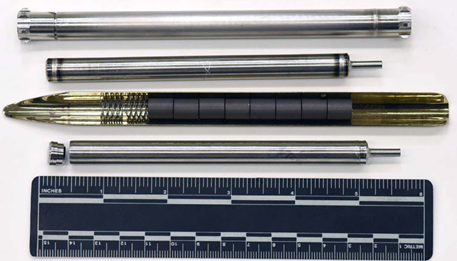

In Phase 2, under way now, the fabrication process has expanded to industrial scale for lead test rods (LTRs) and lead test assemblies (LTAs). Hayes said the ATF-2 test train is scheduled to go into ATR’s pressurized water loop by the end of May.

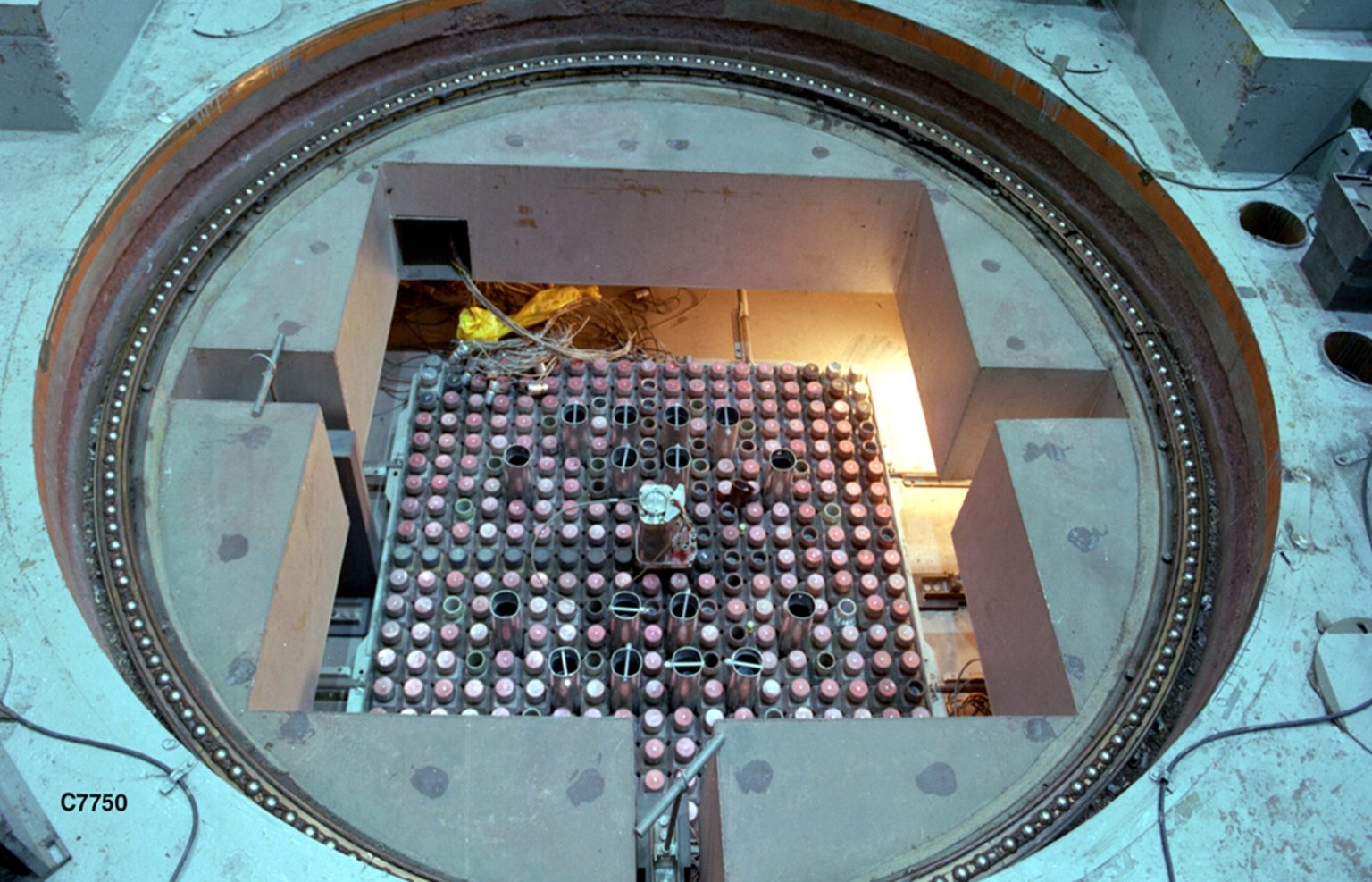

The unique cloverleaf design of the ATR provides a customizable testing environment for multiple experiments using different materials. The second series of ATF tests will measure fuel-cladding and cladding-coolant interactions, while the third and fourth test series will be conducted at TREAT. The TREAT reactor can be used to push fuel and cladding in an extreme experimental environment to determine the maximum conditions the materials can withstand.

Between the third and fourth series, a lead fuel rod, containing the most promising fuel or cladding material concepts, is planned for demonstration in a commercial nuclear reactor. Although the original plan called for down-selection after each phase of testing and evaluation, DOE has since indicated a willingness to support all the vendors if they are successful with their ATF products. “I think each team will continue to receive DOE support as long as their concepts continue to show promise and make progress,” Hayes said.

The information gathered from INL irradiation experiments and post-irradiation examination will be critical to informing the NRC for its licensing decisions. At the April 12 briefing, Mirela Gavrilas, NRC’s director of safety systems in the Office of Nuclear Reactor Regulation, said they believe it is feasible that ATF fuel batches can be loaded in commercial reactors as soon as 2023.