Spaceships require radiation-hardened electronics. So will new nuclear reactors.

“No new advancements can happen without new instruments,” said Troy Unruh, an Idaho National Laboratory instrumentation engineer. He led an international collaboration to develop a precise neutron detector and a radiation-hardened electronics box.

“If you better understand the neutrons, you’ll have a better understanding of how the nuclear reactors operate.”

Unruh is now one step closer to enhancing that understanding after recently completing initial testing of new sensors and electronic pre-amplifiers developed with South Korean collaborators. The sensors will enhance researchers’ ability to monitor, in real time and with precision, what’s going on deep inside operating nuclear reactors.

The team’s work may help improve the cost and efficiency of fuels, materials and reactor operations. These innovations allow for extending fuel lifespan, and preventing undesirable operational conditions. Such advances could be sparked from these instruments, which use new, innovative features that distinguish them from other tools. The project, Unruh said, is “one small portion of making nuclear reactors the energy choice of the future.”

The trouble with radiation

Broader use of electronics inside nuclear reactors has long been stymied by the damage that radiation causes to electronics, which, at heavy doses over time, renders devices inoperable.

Put simply, electronics go haywire when exposed to reactor-level radiation doses.

In a strong radiation field like a reactor core, small computing units in electronics, called transistors, change in ways that foul their accuracy. At times, a device’s binary communication signals flip, turning zeroes into ones and vice versa, scrambling its ability to read the signals accurately. Researchers call this occurrence a bit flip.

But even when electronics can withstand radiation in high levels, measuring neutrons isn’t as straightforward as a state trooper clocking your speed on a highway with the click of a laser gun’s button.

Neutrons cannot be measured themselves, as they have no electrical charge. Instead, researchers must track charged particles released from materials reacting with neutrons. Moreover, many conventional test reactor neutron measurements can provide only cumulative information, as compared to real-time data.

An ideal sensor would precisely measure neutrons and convey real-time data using electronics that can withstand intense radiation. This month, researchers tested just such a system.

A collaborative team from INL and the Korea Atomic Energy Research Institute (KAERI) developed two innovative instruments that work together to allow for more nuanced understanding of what happens inside nuclear reactors.

New instruments

The INL-developed sensor, called a Micro-Pocket Fission Detector (MPFD), measures the amount of neutrons coursing through a reactor core. INL’s work on the detector first started in 2010, though the technology was developed in the 2000s at Kansas State University – a frequent INL collaborator on the project and Unruh’s alma mater.

Small neutron detectors, several of which are currently being tested in INL’s Transient Reactor Test (TREAT) facility, are needed to enhance research on fuels and materials in test reactors, said Dave Broussard, TREAT facility division director.

“Historically, without small detectors, we have to use conventional measurement tools such as fission wires. With a radiation-hardened MPFD we will be able to reliably provide real-time and time-dependent neutron data for fuel safety research experiments,” he said. “Fuel safety research is the primary research and development mission at TREAT.”

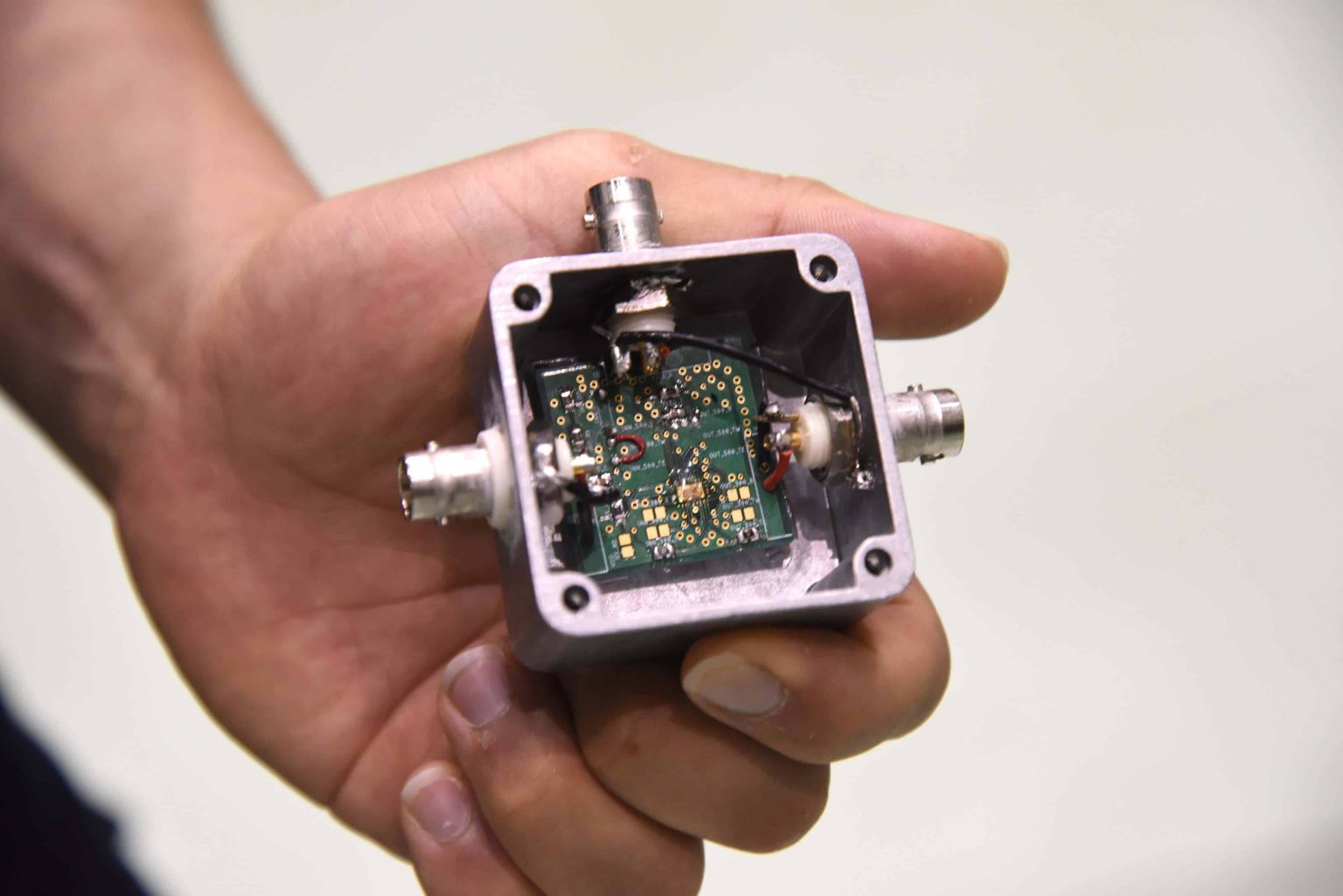

The fission detector can be connected to the KAERI-designed, radiation-hardened pre-amplifier. The device amplifies the sensor’s signals with two circuits that can withstand doses of radiation that normal electronics cannot.

Because a radiation event cannot affect integrated, parallel circuits in two locations simultaneously, KAERI engineers designed a specialized pre-amplifier that can endure reactor-level radiation doses up to simulated accident conditions. The engineers also increased the size of transistors, so their electronic properties are much less affected by radiation.

Both instruments were designed and tested separately to ensure they could endure expected radiation and temperature environments within reactors. For example, the INL neutron sensor was previously tested in TREAT, which creates controlled accident or “crash test” conditions for nuclear fuels.

This month, the collaborative team tested both instruments together for the first time in TREAT.

A promising future

Historical limitations in instrumentation presented many challenges for fuel safety research.

These new neutron detection technologies provide real-time and time-dependent data. Conventional sensors produce only cumulative data over the entirety of an experiment. With the real-time MPFD, even a mid-experiment failure would yield results up to the moment the sensor breaks. Advanced instrumentation such as miniaturized, radiation-hardened neutron detectors will be critical to accurately defining the operating limits of advanced reactor fuels.

KAERI’s lead research engineer for the project expressed an eager hopefulness about the first of many collaborative tests to come. “You cannot be full by the first spoon of food,” said Inyong Kwon, a KAERI senior research scientist.

Researchers hope to deploy the technologies into the next generation of advanced reactors, including microreactors, small modular reactors and other advanced reactor concepts that are different than today’s water-cooled reactors, as well as irradiation test reactors. But before then, the instruments must be thoroughly tested and validated.

So INL and KAERI researchers will continue their tests.

“This is a long-term collaboration,” Kwon said while at TREAT for the tests. “We’re excited to work together more in the future.”

Learn more about INL’s reactor core instrumentation research: https://inl.gov/article/reactor-instrumentation/

Learn more about the Transient Reactor Test Facility: https://inl.gov/360-tour/transient-reactor-test-facility/

Watch a video about the Transient Reactor Test Facility: https://youtu.be/Og7XlWKsAnM