Anyone who has ever cooked a roast knows the value of a meat thermometer. Although you could use a formula that factors weight, temperature and cooking time, it’s better to have a device that tells you the meat’s internal temperature.

For advanced types of nuclear fuel, such precision is not just a convenience — it’s a necessity. Yet until recently, it has been impossible to directly measure temperatures inside nuclear reactor cores. Idaho National Laboratory’s High-Temperature Irradiation-Resistant Thermocouple (HTIR-TC) solves that problem. It faithfully provides nearly continuous, nearly instantaneous temperature readings from inside the reactor.

Surprisingly, until now equipment limitations in nuclear energy have forced engineers to calculate reactor core temperatures based on readings taken at some distance from the fuel. With the HTIR-TC, engineers can place a sensor into a reactor’s heart, even inside a fuel rod itself, getting direct temperature readings in real time. Researchers have actually begun exploring the possibilities of fabricating fuel rods using 3D printing, plasma-spraying ultra-thin thermocouples onto cladding or embedding them in the fuel itself.

Today, nuclear power production is entering its next phase, embracing new technological developments that involve the generation of high heat for advanced manufacturing, hydrogen production and desalination. As these concepts take shape, it is imperative that critical temperatures, such as those within the protective fuel cladding, are measured directly, accurately and reliably, said Dr. Richard Skifton, a researcher in INL’s Measurement Science Department.

A thermocouple consists of two wire legs made from different metals, welded together at one end. Due to a phenomenon known as the Seebeck effect, one can use the difference in voltage across the two materials to calculate a temperature reading. Thermocouples have been used for decades to measure temperatures in ovens, kilns, furnaces and jet engines, as well as in pasteurization and food production.

In nuclear research, however, the high temperatures and radiation levels inside reactor cores create conditions in which conventional thermocouples cannot survive for any great length of time. Even specialized thermocouples made of platinum, which have been shown to withstand temperatures over 2,000°C, are susceptible to neutron bombardment that causes the wire strands to deteriorate, granulate or transmute into different element compositions.

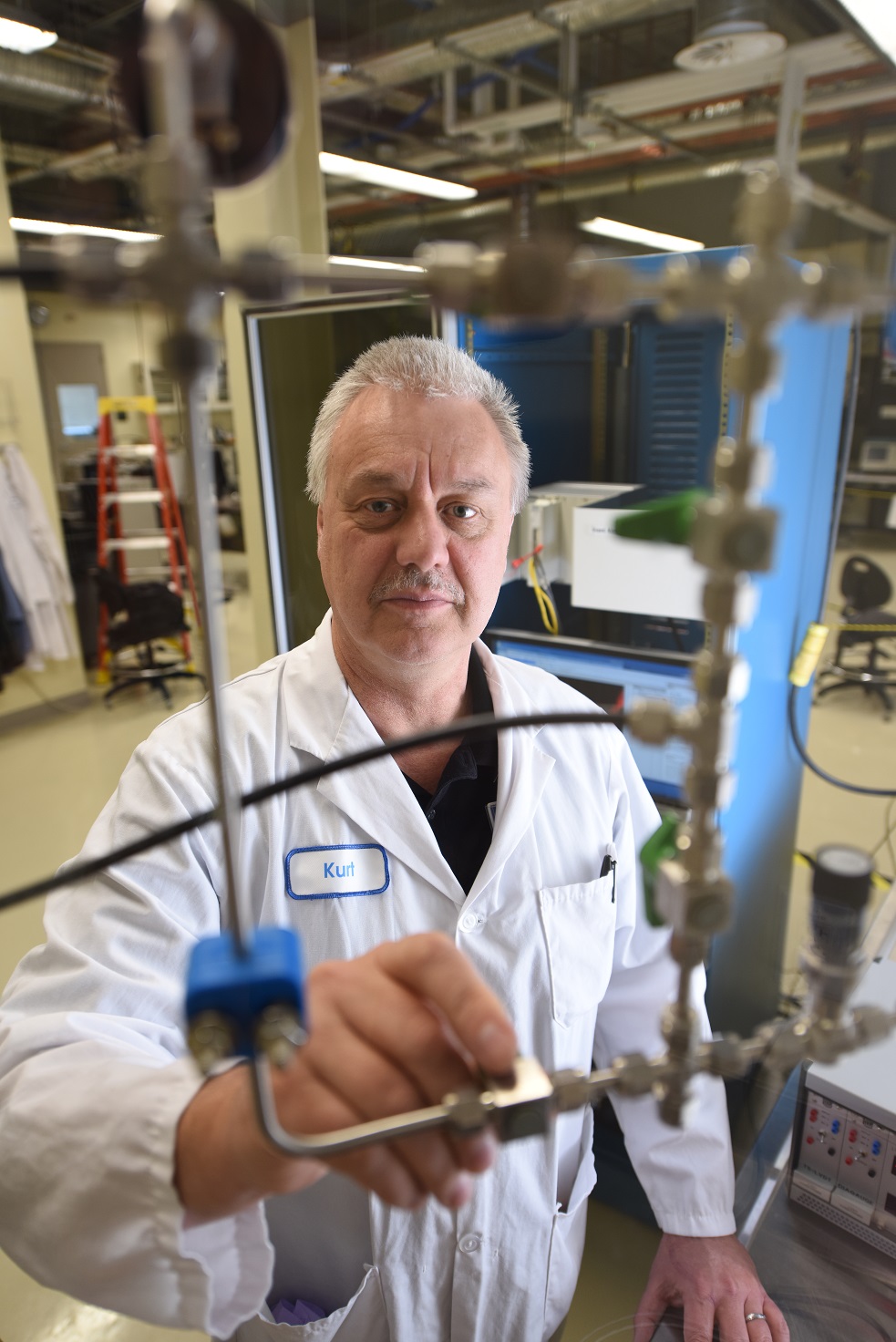

Because of its patented molybdenum-niobium construction, the HTIR-TC is the only high-temperature (>1,250° C) probe that can withstand the environments inside reactors and nuclear fuel rod assemblies for sustained periods of time.

Between now and 2030, new reactors from at least three private companies are expected to come online, operating at lower pressure but much higher temperatures than those in traditional light water reactors. These reactors offer even safer and more economical power production, but will require new fuels, cladding and structural materials.

Engineers will need detailed data to characterize fuels and materials in extreme conditions, and the Nuclear Regulatory Commission (NRC) will require exact and exhaustive test data before certifying that they’re safe to use. To maintain the safety and long-term reliability of these reactors once they’re in operation, new temperature sensors and methods for in-situ measurements will be necessary.

Skifton said he and his team are encouraged by test results they have seen from HTIR-TCs that have been inside INL’s Advanced Test Reactor for more than a year. At temperatures nearing 1,500° C, they have shown consistent readings, with very little variation or drift.

“To our knowledge, this is the highest sustained temperature ever measured inside a nuclear reactor,” INL mechanical design engineer Joe Palmer reported during his presentation at the 2019 Nuclear Plant Instrumentation, Control and Human-Machine Interface Technologies conference this year.

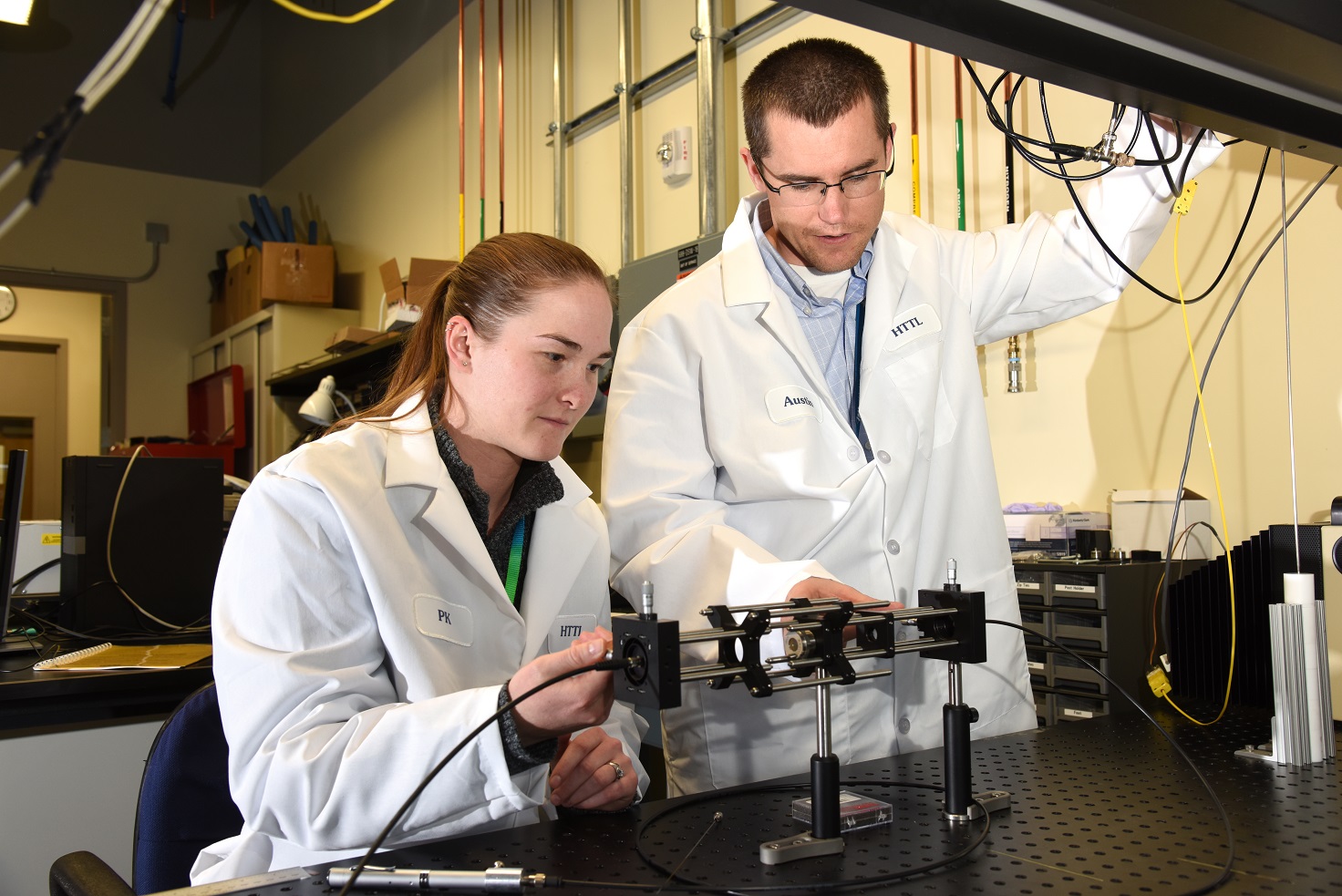

While that team validates the HTIR-TC, others are testing new manufacturing approaches for such high-performance sensors.

INL has collaborated on 3D printing tests with Boise State University and installed its own 3D printer in an INL Research Center laboratory. Although 3D printers have gained wide applications in many industries, “For nuclear, it’s an application that’s still in its infancy,” said Dr. Pattrick Calderoni, the Measurement Science Department manager. “For sensors, the key is demonstrating that we can print electrodes onto insulating ceramic material in a way that doesn’t affect the stability of the interfaces.”

In collaboration with Dr. David Estrada at Boise State, researchers have used 3D printers to print submillimeter-sized sensors onto dosimeters, which will in turn be subjected to extreme conditions in INL’s Transient Reactor Test (TREAT) Facility.

Before any sensors can be printed or embedded in pre-irradiated cladding or fuels, simple proof of concept tests have to be done, said Troy Unruh, another instrumentation researcher. “Can we show that they print, and can we show they can measure temperature?” he asked. “The technology is moving so fast, we don’t know what will be possible in five years. We may be able to print fuels, print structures, embed sensors and take measurements we’ve never been able to take before.”