Similar to how automobile engineers crash test cars, nuclear researchers conduct tests of new fuels, materials and sensors to ensure their safety and performance.

These tests typically take place in test reactors, special nuclear reactors designed to maximize the production of neutrons where test samples can be inserted into the heart of a neutron field.

Weeks or months of neutron bombardment in a test reactor such as Idaho National Laboratory’s Advanced Test Reactor might mimic years in a conventional or advanced nuclear power reactor. Experiments in the lab’s Transient Reactor Test Facility (TREAT) can simulate more extreme conditions with intense bursts of neutrons to intentionally damage materials.

To then assess the damage, researchers must conduct careful examinations of the fuel, sensor or material.

To aid with those examinations, INL and the Heinz Maier-Leibnitz Institute at Technical University of Munich (TUM) have developed a digital neutron computed tomography system. The system was installed at INL’s Neutron Radiography (NRAD) Reactor, a 250-kilowatt test reactor on the INL Site west of Idaho Falls, Idaho.

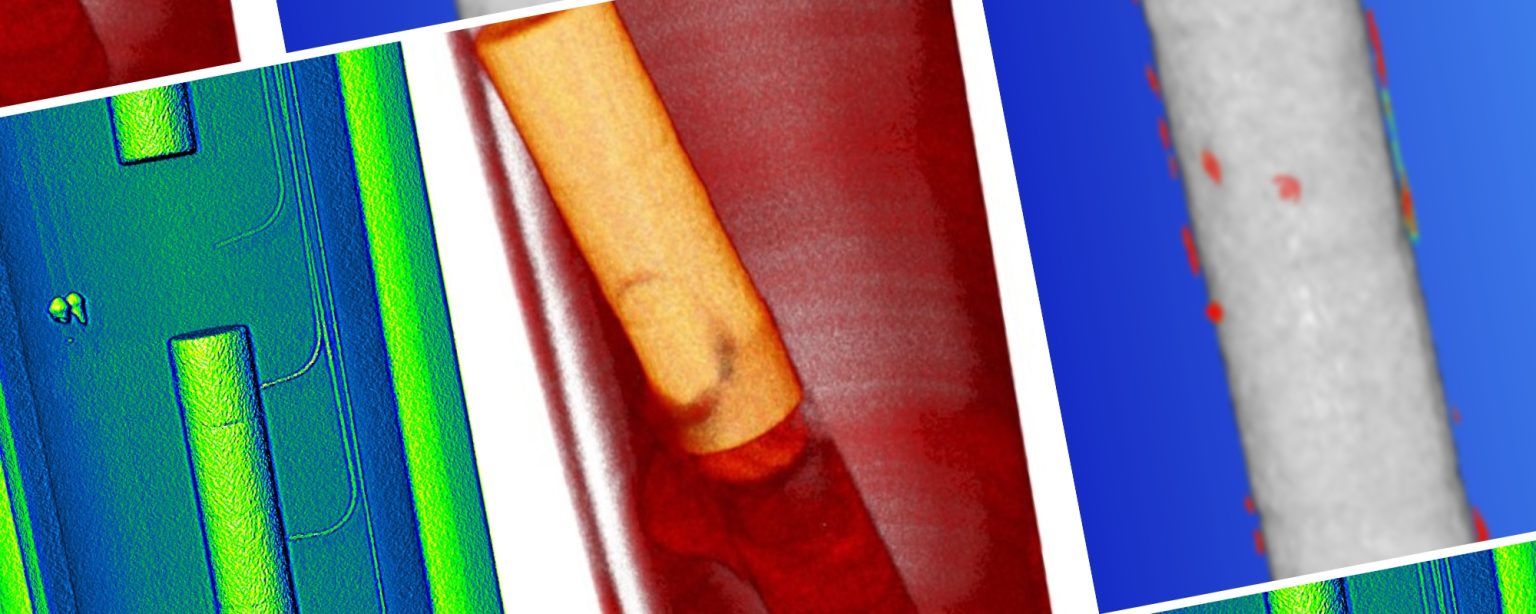

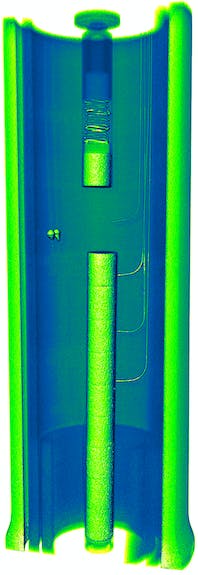

In the same way that a computed tomography (CT) scan makes 3D X-rays of the human body, the digital neutron computed tomography system is capable of making 3D images of nuclear fuels and reactor components using multiple neutron radiographs.

The neutron CT scan “is like a diagnosis,” said Dr. Aaron Craft, an INL researcher who led development of the system. “We’re using neutron tomography to diagnose fuel that is intentionally damaged in a test reactor such as TREAT.”

In a typical CT scan, the X-ray machine is rotated around the object to capture the necessary images. However, since the neutron beam coming from NRAD’s reactor core cannot be rotated, the neutron CT system rotates the object in order to get the multiple radiographs needed to create a 3D image.

“We take radiographs at different angles and then mathematically reconstruct them into a 3D representation of the object,” Craft said. “One of the big advantages is that it’s nondestructive.”

Unlike X-rays, which interact with the electrons of an atom, neutrons interact with the atom’s nucleus. The result is better penetration through metals and a better image of components containing hydrogen. While X-rays are useful for imaging materials such as bones, neutrons can capture images of materials that X-rays cannot penetrate, such as the dense components of nuclear fuels.

Researchers often take complementary high- and low-energy neutron radiographs, which together can offer a better understanding of a given test material. Further, neutron radiographs are not as sensitive to the gamma radiation coming off irradiated nuclear fuel, which can reduce the image quality of an X-ray.

In the past, neutron radiographs were developed using a complicated process not too dissimilar from older, chemical photography techniques. But Craft has built a system using digital cameras that are shielded against radiation.

Without digital radiography, taking a full set of film radiographs might take a month or more.

But a typical radiograph is limited. “The 3D neutron CT scan reveals details you would never be able to see in a 2D image,” Craft said. For example, a single radiograph would not necessarily give enough information to determine whether temperature sensors are still attached to the cladding of a fuel rod or the presence of cracks.

One complexity to the 3D imaging: how to automate the sample movement with acquisition of hundreds of digital images. The solution at NRAD emerged from a collaboration with Dr. Burkhard Schillinger from TUM in Germany.

TUM developed and gave INL a customized control system for the imager that was specifically adapted for use at NRAD. The system allows researchers to automate the imaging process, which can require hundreds of radiographs. A computer then assembles the 2D radiographs into a 3D image.

The neutron CT system recently produced the world’s first digital neutron CT scan of irradiated nuclear fuel. The resulting 3D reconstruction shows a test fuel rod that broke after testing in extreme conditions at TREAT.

TUM performed initial tests of the system at its FRM II reactor. While the FRM II reactor in Munich is not capable of performing examinations on highly radioactive nuclear fuel, it is providing high-resolution test measurements at different energy levels to aid development of new, higher resolution radiography techniques. Radiographs made using multiple energy neutrons will allow deeper insights into the properties of nuclear fuel.

“The neutrons are traveling at a higher speed,” Craft said, explaining that while low energy neutrons travel at almost 5,000 miles per hour, high energy neutrons would travel at several times that speed. “High energy gives you better penetration.”

These new imaging capabilities from INL and TUM will assist with a worldwide effort to develop new low-enrichment fuels for research reactors, many of which still require high-enrichment fuel to deliver optimum scientific results.

While conversion to low-enriched fuel is challenging and may take several years, advancements in examination technology such as the digital neutron computed tomography system may accelerate development of low-enriched fuels.

LEARN MORE

For information about other NRAD projects, visit: https://inl.gov/article/neutron-radiography/

For information about NRAD’s latest upgrade, visit: https://inl.gov/article/neutron-radiography-reactor-restarts/

By Cory Hatch for INL Communications & Outreach