The first magnifying lenses appeared in the 13th century, invented to aid those with poor eyesight. Technological improvements eventually led to microscopes and telescopes, opening our eyes to the tiny worlds right in front of us and the vastness of space over our heads.

More refinements to the technology brought us high-powered electron microscopes and the Hubble Space Telescope, leading to breakthroughs in fields such as astronomy, biology, surgery and more.

Science always moves forward. But sometimes it’s good to pause and recognize the progress that’s been made.

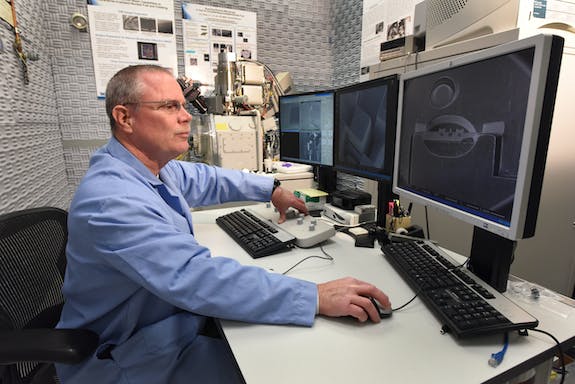

That’s why James Madden had mixed emotions when he emailed colleagues to let them know that an important piece of equipment was being decommissioned at the Materials and Fuels Complex’s Electron Microscopy Laboratory.

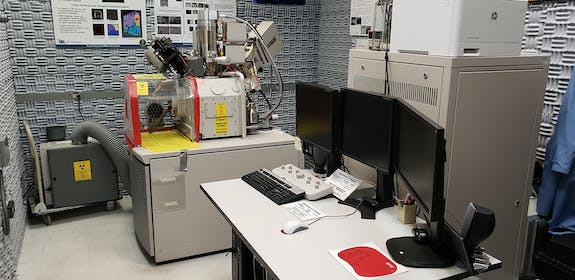

“Just wanted to let you know that the EML Quanta 3D FEG, the FIB that proved everyone wrong about using a focused ion beam (to study irradiated materials), is being decommissioned starting today,” Madden’s email read. “It’s a little sad to see her go but we will replace her with something better, with stronger abilities and higher performance.”

The equipment Madden referenced in his email was a scanning electron microscope, known as a SEM, equipped with a focused ion beam, known as a FIB. It was used for groundbreaking work studying irradiated fuels and materials.

The microscope, called “the FIB” by those who worked closely with it, proved that similar high-end characterization equipment, like the tools that now fill INL’s state-of-the-art Irradiated Materials Characterization Laboratory, could be safely used to study highly irradiated materials.

“It really was the instrument that started a revolution in the characterization of nuclear fuel,” said Mitch Meyer, director of Characterization and Advanced Post-Irradiation Examination at MFC.

INL pioneers new use for old technology

Similar equipment was standard in other industries, such as the semiconductor industry, but there were doubts it would prove useful to study irradiated materials because of the cost and potential risk to people and equipment.

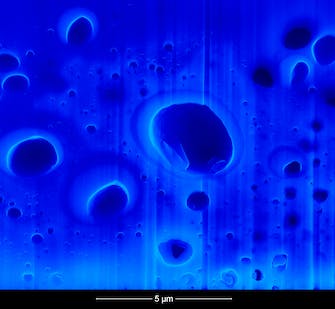

But the capabilities provided by that equipment were needed to advance the study of irradiated fuels and materials, which weren’t well understood at the nanometer (one billionth of a meter) and atomic scales. Maybe even more importantly, traditional sample preparation methods didn’t work well with highly radioactive materials, making it even harder to study using other pieces of equipment.

Additionally, the areas of predictive modeling and computer simulation needed better real-world data to validate the results their high-end computers were producing.

There was a push in 2008 to see if the state-of-the-art tools and techniques available in the general research community could be used to modernize the study of irradiated nuclear materials. Jim Cole led the team that brought the FEI Quanta 3D FEG to INL. His team purchased the instrument in 2009 as the first test case.

At the time, Madden was working with similar equipment at Micron Technology, a semiconductor company in Boise. Cole posted a job search for a professional microscopist for sample preparation and to develop techniques for use with irradiated materials. The job listing caught Madden’s eye, saying the groundbreaking potential and challenge of figuring out how to make the equipment work in the study of nuclear materials was too interesting to pass up. So Madden applied, and got the job.

“They wanted me to get the FIB up and running and provide knowledge to develop the program but also modernize their labs,” Madden said. “EML and (the Fuels and Applied Sciences Building) looked like machine shops.”

Transforming the study of irradiated materials

Once on-site, Madden teamed with researchers Jan-Fong Jue, Jian Gan and Brandon Miller to figure out how to make it work.

The team started small, using samples with lower levels of irradiation. They gathered information on procedures and the effects on the equipment before moving to more challenging samples. The methodical approach paid off.

“In the beginning, people said we were crazy,” Madden said. “They thought it would contaminate the equipment, but the more we worked with it, we found out it was very safe.”

The team can now do things that were previously unavailable for irradiated materials, including:

- Routine nano and atomic scale characterization

- Prepare samples of irradiated materials to be used on other high-end pieces of advanced imaging equipment

- Decrease radioactivity levels of prepared samples, allowing for safe contact handling

- Minimize instrument contamination

Gan said analyzing the microstructure and microchemistry of irradiated fuels was “extremely challenging” prior to the FIB because it was so difficult to produce high-quality samples of the material.

The new equipment was exactly the breakthrough Gan and other researchers were looking for.

“The introduction of the FIB for irradiated fuel characterization, led by INL, is the most impactful development in the nuclear fuel research and development worldwide,” Gan said.

He said the new equipment could produce sectioned areas with pristine irradiated microstructure for analysis, providing researchers and modelers with data quality that was not possible using conventional sample preparation techniques.

Gan said the improvement was even bigger for those using TEM characterization of highly radioactive materials, including more detailed resolution, shorter sample preparation time and decreased dose exposures.

“With INL’s successful pioneer work of FIB application for irradiated fuel characterization, it brought revolutionary changes to the nuclear fuels R&D in the world now,” Gan said. “I consider this is one of the most impactful works to the world that originated at INL.”

Madden and his colleague look back fondly on the work they did at EML, and are proud of what that work has led to.

“The work here is very challenging, but we’ve shown we can do it,” Madden said. “And the FIB is the piece of equipment that showed it was safe to use high-end quality equipment with highly irradiated materials.

“Who would take the chance of doing this with the equipment? Somebody had to come forward and attempt it and INL decided it was something worth doing. And now it’s a standard in the industry.”

Did you know?

The Quanta 3D FEG that was housed in the Electron Microscopy Laboratory featured a scanning electron microscope (SEM) and a focused ion beam (FIB). The instrument was vital in advancing the study of irradiated nuclear fuels and materials.

What is a scanning electron microscope? A scanning electron microscope, also known as a SEM, uses an electron beam to rapidly scan the surface of a sample specimen to produce an image of the surface topography. The SEM has a resolution of about 10 nanometers.

What is a focused ion beam? A focused ion beam, also known as FIB, is similar to a SEM, but instead of using electrons, the FIB uses a focused beam of ions to modify or mill with nanometer precision a specific area of interest on the sample.

How do they work together? When the SEM and FIB are combined in the same machine, like the Quanta 3D FEG, the beams work together to provide high-resolution SEM imaging of the FIB-milled surface.