Over six weeks during the summer of 1977, the two Voyager spacecraft launched from Cape Canaveral, Florida. In the 42 years since, they have traveled more than 11 billion miles from Earth.

Along their journey, the spacecraft have provided stunning images of planets such as Saturn, Jupiter, Uranus and Neptune and their moons. They’ve gathered reams of data that have helped scientists probe the secrets of the universe. In 2012, Voyager 1 became the first man-made object to pass the edge of the solar system and enter interstellar space, followed by Voyager 2 six years later.

At the heart of these two spacecraft – providing electricity to the computers, spectrometers, magnetometers, radiometers and other subsystems that help the Voyagers fulfill their respective missions – are radioisotope thermoelectric generators (RTGs) powered by plutonium-238 (Pu-238).

The same is true for Cassini, Galileo, the Viking landers, Mars rover Curiosity, New Horizons and more than two dozen additional satellites, spacecraft and vehicles. For these space explorers, the lack of sunlight, rugged conditions or the length of the mission necessitate a robust, long-lived power supply.

“Without plutonium, we couldn’t really do a lot of the most important missions,” said Carla Dwight, who serves as INL’s Isotope Production Programs manager in the Space Nuclear Power and Isotope Technologies division.

A precious resource

While the United States has enough plutonium to fuel the space missions scheduled for the next decade, the domestic supply of plutonium is a limited resource. In order to establish a new supply of Pu-238 to enable future NASA missions, Congress directed the Department of Energy (DOE) to resume Pu-238 production.

Pu-238 gives off a large amount of heat due to radioactive decay during the course of its 87.7 year half-life. “Other radioisotopes have been studied and used in the past for radioisotope power systems, but Pu-238 has the best properties for conversion from heat to electricity for space missions,” Dwight said. “It’s been used safely since the 1960s.”

An RTG converts that heat directly into electricity using specialized thermocouples—devices that make electricity without moving parts that might fail during a long space mission.

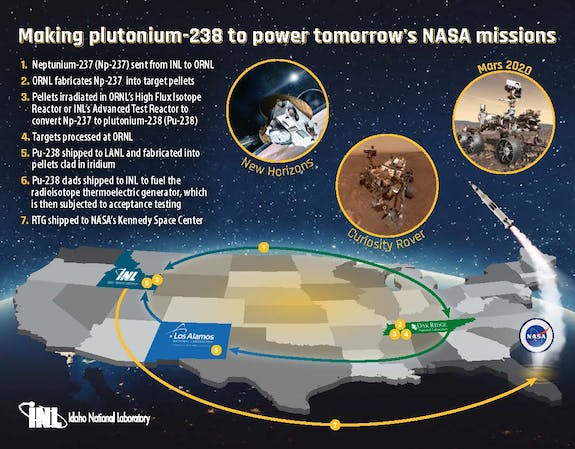

To make Pu-238, DOE repurposes some of its stockpile of neptunium-237 (Np-237)—a complicated process, involving experts and equipment at three national laboratories.

A cross-country journey

The steps to produce new Pu-238 require many facilities and unique processing capabilities. They can be summarized into three major steps: fabrication, irradiation and separation. First, researchers at Oak Ridge National Laboratory blend a powdered form of Np-237 with aluminum powder, press the mixture into pellets about the size of a pencil eraser, and load those pellets into aluminum tubing that is welded closed resulting in a fabricated target.

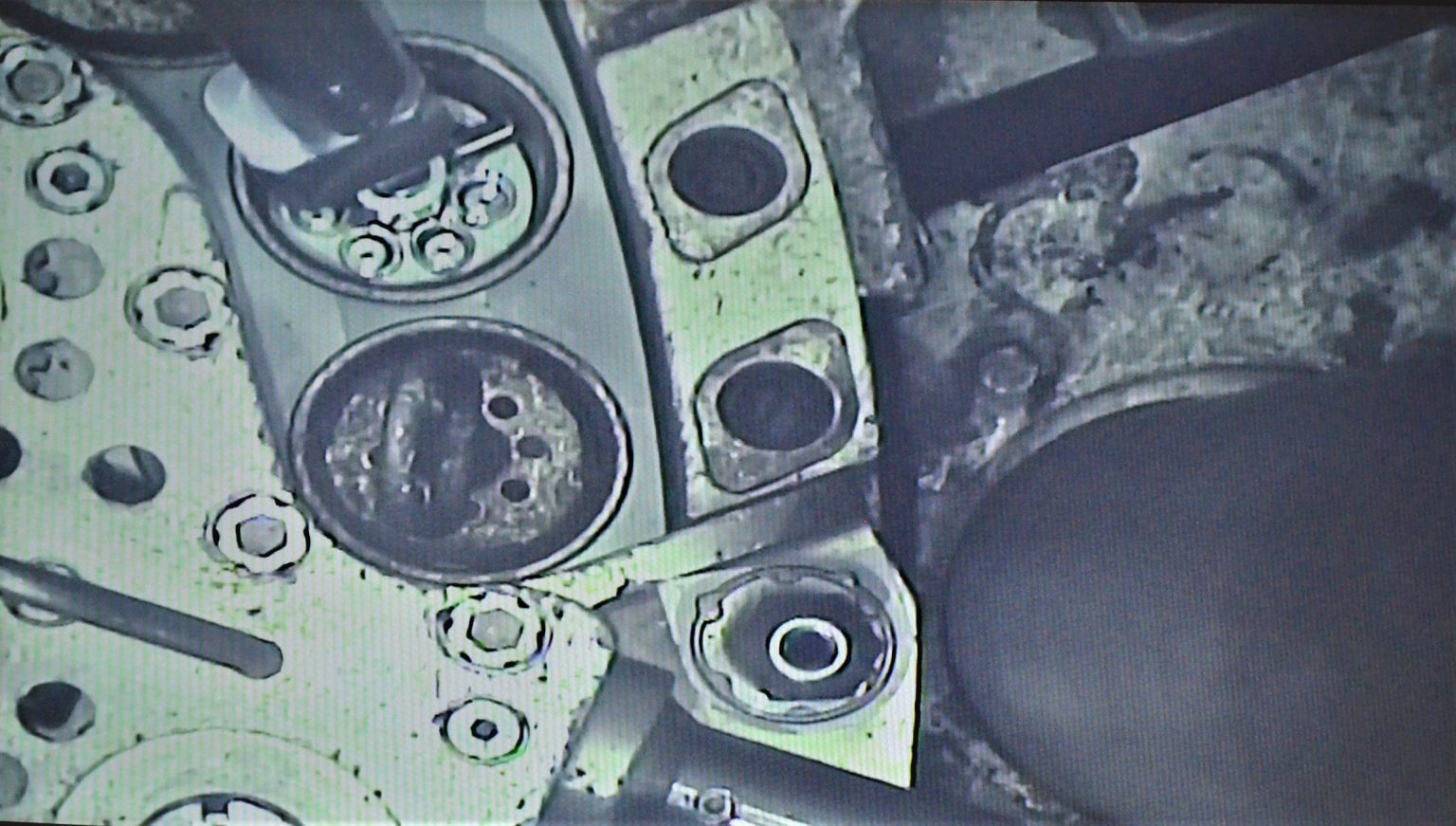

These targets are grouped in bundles, for convenient handling, and then placed in one of two available reactors well suited for the next step—irradiation. Both Oak Ridge’s High Flux Isotope Reactor and Idaho National Laboratory’s Advanced Test Reactor receive and insert the bundled targets into reactor positions, where they are bombarded with a prescribed amount of neutrons for multiple reactor operating cycles. This process causes a percentage of the Np-237 to be converted into Pu-238.

After the targets are irradiated, they’re allowed to cool in the local reactor pool and then shipped back to Oak Ridge where they are chemically processed. Chemical processing of these irradiated targets provides the next critical step—separation. What’s left is a mixture of 85% to 90% residual Np-237 and 10% to 15% newly produced Pu-238 with small quantities of other isotopes. The two key materials, plutonium and neptunium, are separated and the Pu-238 is converted to oxide. The Np-237 is recycled back to the target fabrication step.

The Pu-238 oxide is then packaged for shipment to Los Alamos National Laboratory where it is blended with fuel already in inventory to meet NASA’s specifications.

The Pu-238 oxide is compressed into pellets and placed into a shell of iridium, a metal that, when hot, can be deformed without breaking. The iridium cladding is a safety layer designed to keep the Pu-238 oxide pellets contained in case of an accident during launch or re-entry into the Earth’s atmosphere. These “fueled clads” are quality checked at LANL, and then shipped to INL where they are stored in a flight-ready state for future RTG fueling.

The end of a mission

The Voyager missions were originally intended to last only five years. By now, the Pu-238 powering the Voyager spacecraft has decayed to the point that NASA engineers have begun shutting down scientific equipment in order to save power. By 2025, NASA says, the Voyager spacecraft will finally stop collecting data and sending it to Earth.

The Voyager spacecraft continues to function in the dark and cold of interstellar space 37 years after their mission was planned to end, which is a testament to the reliability of Pu-238-powered RTGs.