Idaho National Laboratory wins four R&D 100 Awards

Four Idaho National Laboratory technologies won R&D 100 Awards in 2021.

This prestigious innovation awards program celebrates technology research and development, with awardees selected by a panel of industry-leading expert judges from submissions made across the public and private sector. U.S. Department of Energy national laboratories typically have dozens of finalists each year.

INL has won more than 30 R&D 100 Awards since 2005.

Additionally, INL had two technologies recognized as finalists.

Winning technologies led by INL:

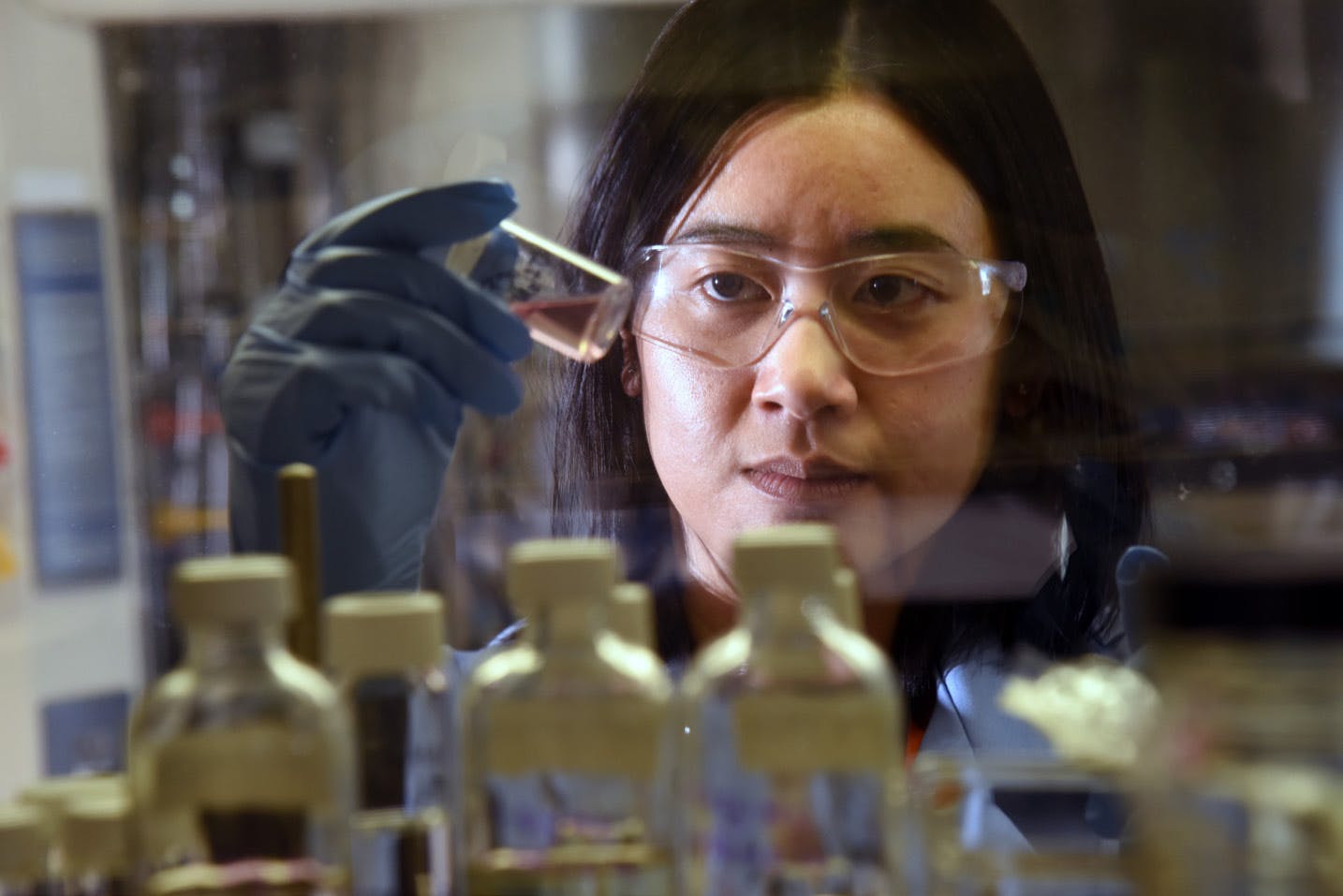

RE-Metal

Donna Baek, Robert Fox, Abderrahman Atifi

RE-Metal helps solve an enormous challenge for U.S. manufacturers: enabling the environmentally friendly recycling of a limited supply of essential rare earth elements that are required for most of today’s high-tech devices. Recycling rare earth elements from high-tech devices typically involves a toxic process that’s banned in many countries, including the United States. RE-Metal enables the recovery of rare earth metals from waste electronics and other sources.

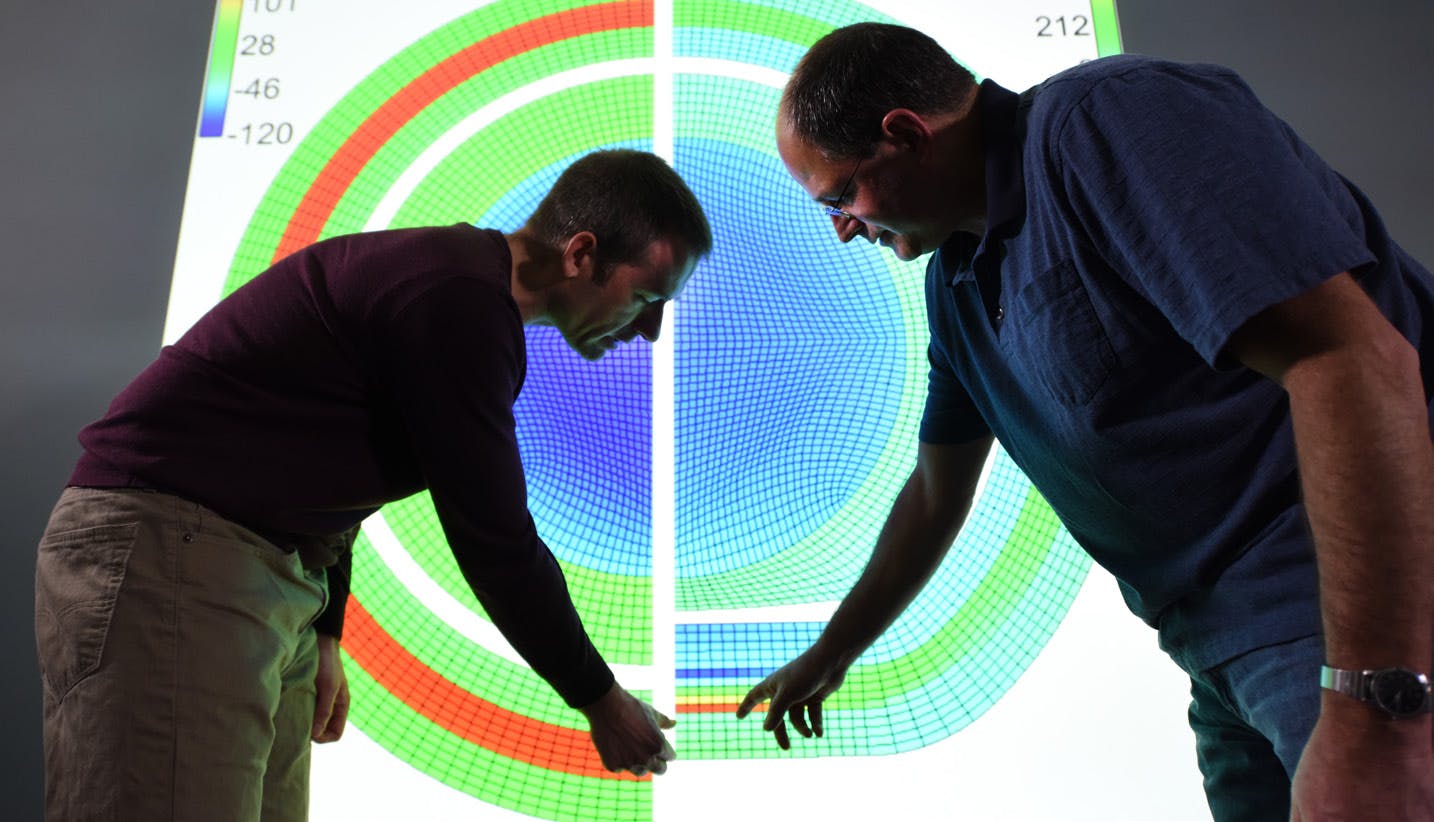

Bison

Jason Hales, Richard Williamson, Albert Casagranda, Kyle Gamble, Stephen Novascone, Stephanie Pitts, Gyanender Singh, Benjamin Spencer, Aysenur Toptan, Wen Jiang

Bison is a flexible, next-generation nuclear fuel performance analysis code that is unique in its ability to analyze fuels of varying types and geometries in one, two or three dimensions. By making advanced simulation more accessible to nuclear engineers, Bison will help enhance the safety and effectiveness of existing nuclear plants. It also is enhancing safety and efficiency for the next generation of reactors.

Commercial Routing Assistance Tool

Ollie Gagnon, Robert Edsall, Mary Klett, Timothy Klett, Michael Overton

The Commercial Routing Assistance Tool is an interactive website that maps routes and displays information about state government actions that can impact interstate transportation. The tool produces routes for commercial, emergency and disaster response vehicles to travel into or around various states in an efficient, compliant and safe manner.

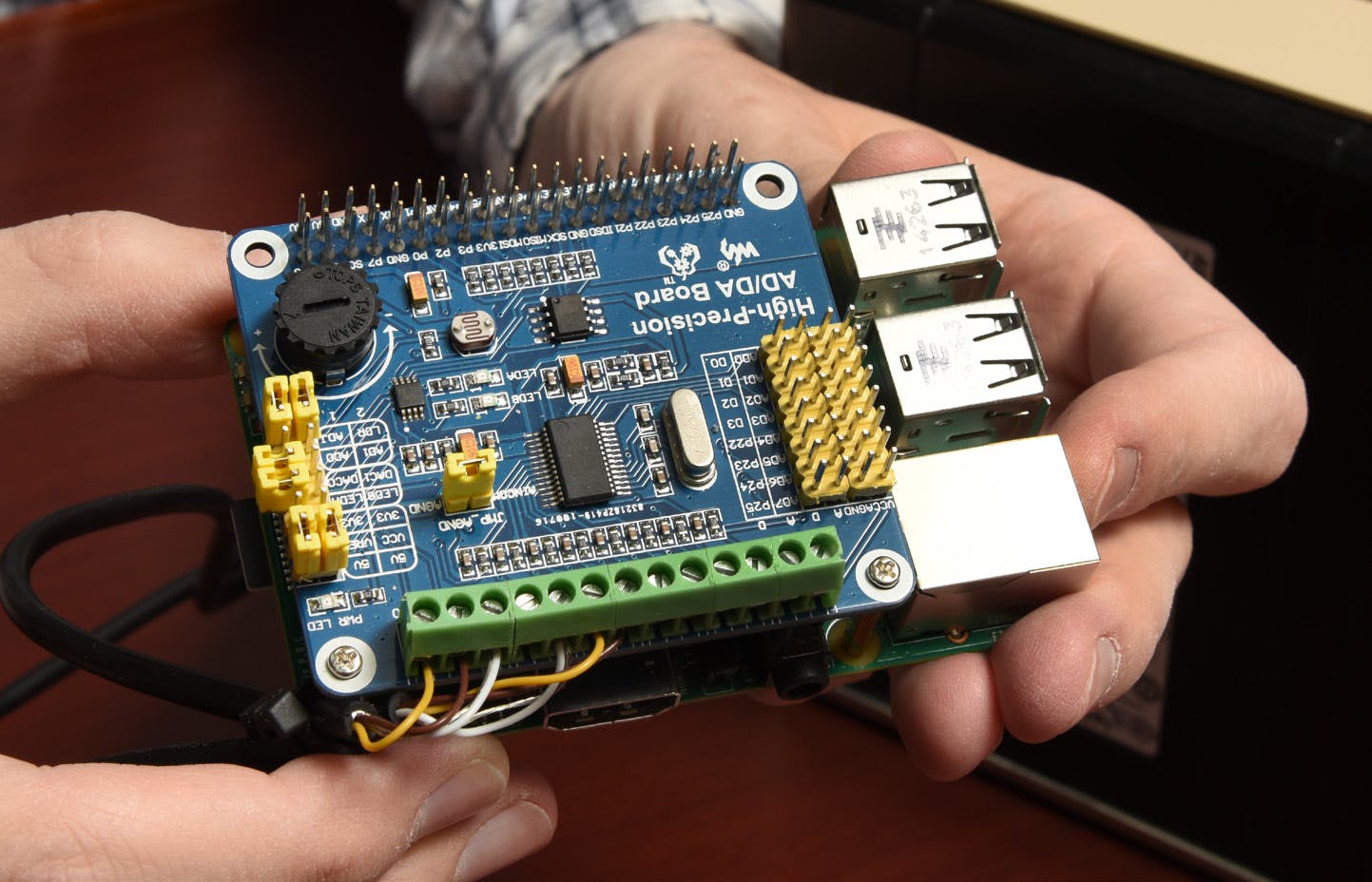

Plug-N-Play Appliance for Resilient Response of Operational Technologies (PARROT)

Craig Rieger, Edward Springer, Michael McCarty, Timothy McJunkin

The Plug-N-Play Appliance for Resilient Response of Operational Technologies (PARROT) provides an extra layer of security from cyberattacks on critical infrastructure operations. When placed between control systems and infrastructure, PARROT isolates a cyberattack, provides a manual or automated response, and prevents harmful impacts while maintaining operations.

Finalist technologies led by INL:

Wireless Valve Position Indicator Sensor System

Vivek Agarwal, John Buttles, Robert England

Safety and efficiency at most industrial facilities depend on having valves positioned correctly. Leveraging advancements in sensor and wireless communication technologies, Valve Position Indicator allows for monitoring the position of valves from a remote location, cutting manual inspections, verification, unnecessary maintenances and calibrations, and labor costs while protecting against cyber sabotage.

Carbon CACHE (Ceramic Anode Cell with High Efficiency)

Dong Ding, Ting He, Wei Wu

Carbon CACHE is an advanced direct carbon fuel cell that uses solid carbon as fuel. It offers much cleaner and more efficient electricity generation compared to combustion-based technologies from resources such as coal and biomass. It could also reduce the cost of carbon capture to address climate change.