Figuring out what happens to a material over time can be tough – especially in harsh environments. Scientists would like to probe materials while subjecting them to heat, radiation, and other extreme environmental conditions. Now, researchers are one step closer to this capability, with a demonstration to show that light-generated sound waves can remotely and nondestructively reveal a material’s inner structure.

Researchers from Idaho National Laboratory (INL) were part of a multi-institution team that reported on progress in this area in a Nature Communications paper, “Imaging grain microstructure in a model ceramic energy material with optically generated coherent acoustic phonons.”

That title is a mouthful, said David Hurley, an INL fellow and director of the Center for Thermal Energy Transport under Irradiation, as well as one of the paper’s co-authors. He noted that the last word, phonons, refers to vibrations in crystals.

“At very low frequencies, they’re essentially acoustic waves,” he said. “At higher frequencies, we call them phonons and they’re responsible for carrying heat in ceramic materials.”

Hurley said this type of imaging will give clues about how the structure of a material changes over time. The ceramic energy material could be uranium oxide and thorium oxide (found in nuclear reactors), cerium oxide (appears in fuel cells), silicon, gallium arsenide or cadmium telluride (important in photovoltaics, also known as solar cells).

So, being able to see how these various materials evolve over time and under extremes of stress, temperature and radiation is important to a range of energy industries.

What is an optically generated acoustic phonon?

So, how do you make a sound wave in these ceramic materials?

You hit it with a pulse of light.

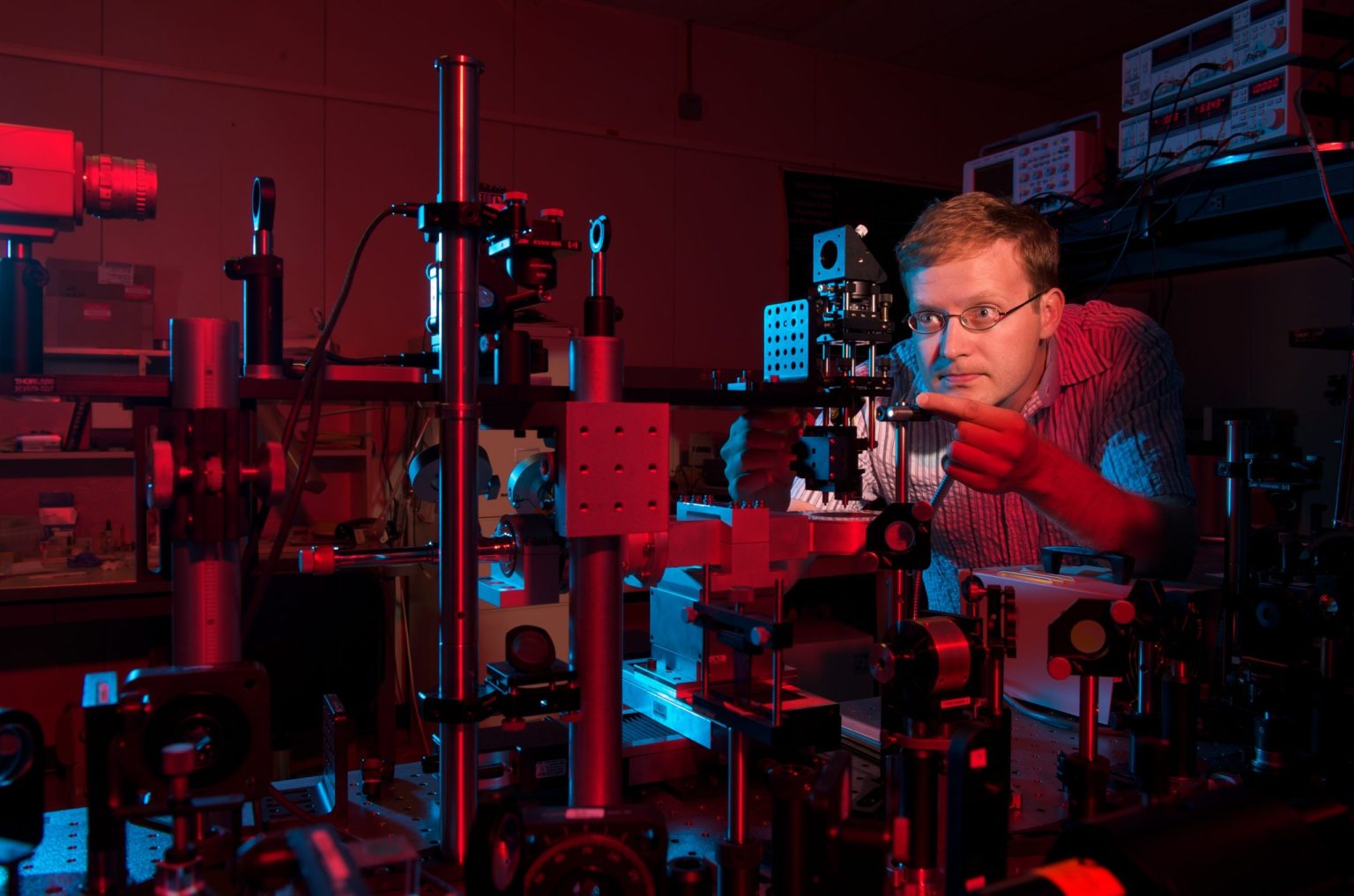

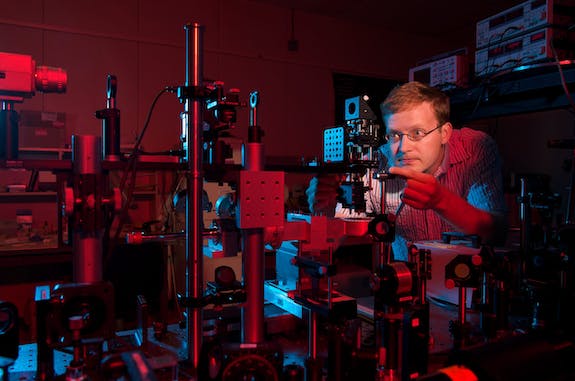

In their investigations, the researchers used a laser, with a pulse duration of a picosecond – or a trillionth of a second. The laser fired pulses 76 million times a second, and the scientists sent that stream of pulses into the surface of the sample being studied. Each pulse dumped energy into the material, causing it to expand very slightly and thereby generate a sound wave that propagated from the point of origin through the sample.

After pumping energy into the sample (with a “pump beam”), the researchers probed it, using another beam of light (the “probe beam”) that was slightly delayed from the pump beam. Some of this probe beam reflected off the surface, and some of it traveled into the material to reflect off the moving sound waves. That made it possible to determine important material characteristics.

In their experiments, those phonons were propagating through ceramic materials, and the materials had a polycrystalline microstructure. That is, for small regions they had a regular array of atoms with a defined spacing and orientation angle between them, much like crystalline structure found in diamond. These small regions are referred to as grains. Those laser-produced sound waves revealed information about the material, a result of what happens when you make sound using light.

“You get three frequencies and that tells you something about the crystal orientation,” Hurley said.

What the researchers showed is that by using different polarizations of the probe laser, they could extract the complete orientation of individual grains. In this way, they could image the grain microstructure, the arrangement of atoms in the polycrystalline microstructure.

The work was led by The Ohio State University, a member of INL’s National University Consortium.

Getting the picture

Such imaging is important because grains in a ceramic energy material can grow and change over time. The fuel in a nuclear reactor, for instance, undergoes a lot of grain restructuring in response to the environment, according to Hurley. The desire, therefore, is to be able to determine what’s going on with the material during actual operation of a nuclear power plant.

The light-generating-sound approach could prove a useful way to do this. For one thing, it provides information without damaging the material. The only other way to get the microstructure information is destructive and can be slow, depending on the size of the sample. In contrast, using optically generated acoustic phonons as a probe makes it possible to get data on the same sample repeatedly over time in realistic operating conditions including extremes of stress, temperature, and radiation. Plus, it can be orders of magnitude faster.

Another key advantage is that the sound-based method can be combined with optical spectroscopy, which provides information about a sample’s chemical composition. And other optical methods and instruments can be employed.

“So, you’re characterizing multiple things about the sample simultaneously,” Hurley said.

The capabilities demonstrated in the paper are already being put to use in new research. For instance, looking at what happens to the grains as temperature changes could lead to better understanding of what limits a material’s thermal conductivity—the degree to which it conducts heat. Such information could be important in designing higher performing materials for tomorrow’s reactors, fuel cells and photovoltaics.

Thus, making sound from light could be an important tool in a range of industries.