Using the right construction material is important. Just ask the third of the three little pigs. That star of the children’s tale would say selecting the proper material was the key to success.

The same principle holds in the real world. So, to help engineers and others pick the right material, the American Society of Mechanical Engineers (ASME) publishes the “Boiler and Pressure Vessel Code” – also referred to simply as the Code. It lays out design rules for how much stress is acceptable and specifies the materials that can be used for power plant construction, including in nuclear power plants. Adhering to these specifications ensures component safety and performance.

Now, a team at Idaho National Laboratory in collaboration with groups at Argonne and Oak Ridge national laboratories, as well as industry consultants and international partners, has for the first time in 30 years gotten a new material, Alloy 617, into the Code. A combination of nickel, chromium, cobalt and molybdenum, Alloy 617 can be used in tomorrow’s advanced nuclear plants because it allows higher temperature operation.

“It’s a pretty substantial accomplishment,” said Richard Wright, an INL laboratory fellow emeritus, of the successful yearslong effort to get Alloy 617 into the ASME standard. Wright headed the INL part and overall management of the project.

The achievement means that designers working on new high temperature nuclear power plant concepts now have 20% more options when it comes to component construction materials. “In contrast to light water plants, the commercial fleet, where you might have 50 or 100 materials that you could use, there were exactly five you could use for high temperature reactors,” Wright said.

Alloy 617 took so long to make its way into the standard because of physics and the way materials are added to standards. Each aspect took years to complete.

Creeping along

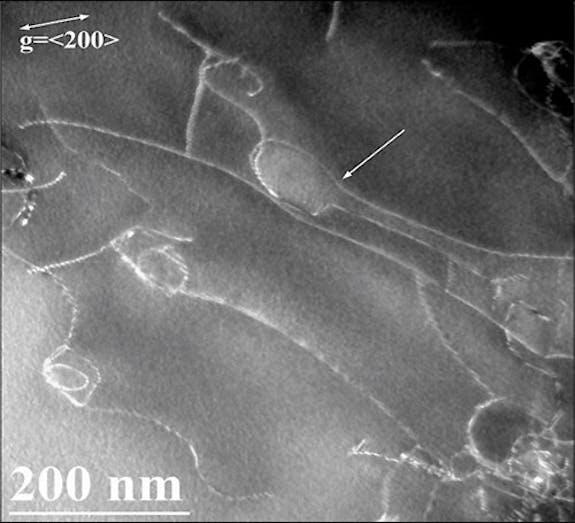

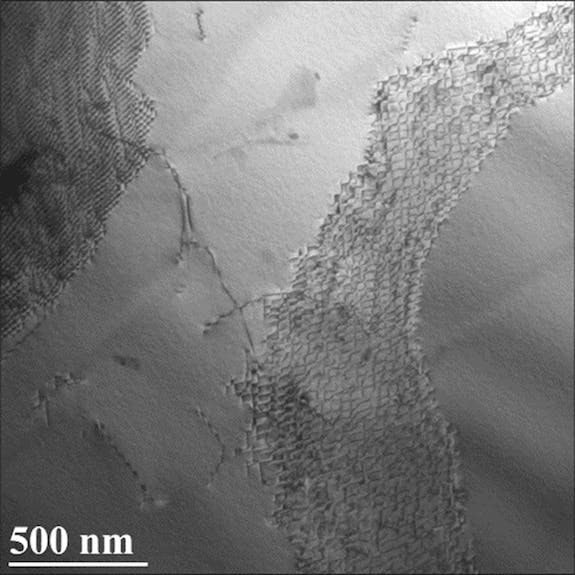

Regarding the physics, Wright said the issue has to do with creep – the tendency of a substance to change shape over time. Creep only becomes an issue starting at about half the melting point of a material. The lack of creep is why a car can sit in the driveway for years without the metal deforming.

But at higher temperatures, creep happens, and it will be a factor in new proposed reactors. Unlike light water reactors that operate at around 290o C (about 540o F), the proposed molten salt, high temperature, gas-cooled or sodium reactors will run two or more times hotter. So, determining what happens to Alloy 617 over time at a given temperature was critical. However, that job was not easy.

“These time dependent properties get to be really tricky to measure and understand,” Wright said.

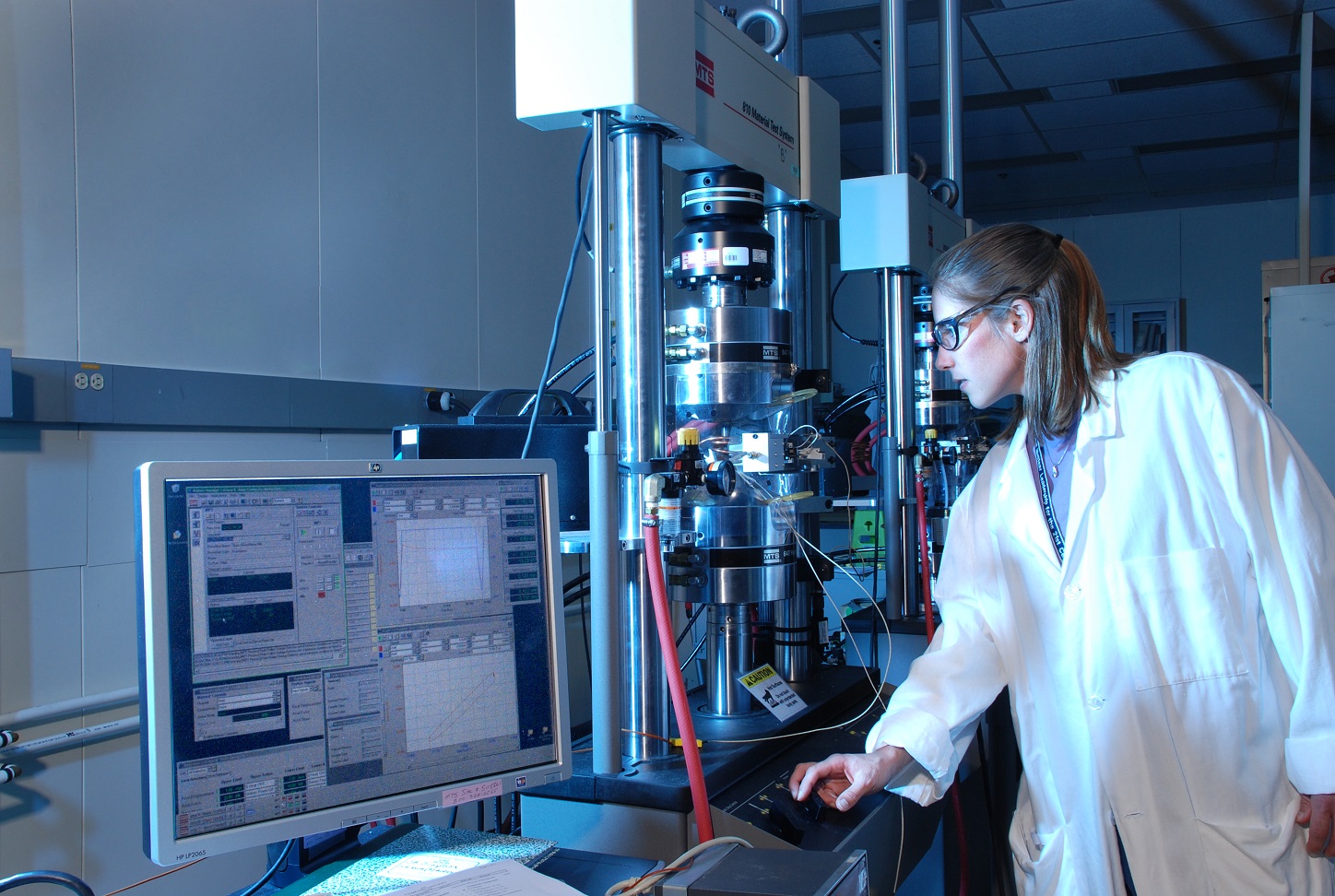

What’s more, any measurements had to be done on different batches of Alloy 617 to account for slight variations in composition and manufacturing. Some of the tests were quick, like measuring how much stress the material could take before it breaks. But some of the tests, like those involving creep, take years.

ASME permits a threefold extrapolation factor for time. In other words, to qualify a material for 100,000 hours, or 11.4 years of operation, researchers must gather data for 33,000 hours – or 3.75 years. That mark is about the minimum a new material must be qualified for, as power plants are designed to run for decades.

After gathering the data on Alloy 617, the researchers came up with conservative figures to go into the ASME specification. They then submitted this proposal for balloting, starting the next phase of the process to get the material into the Code.

Balloting, one step at a time

In organizations like ASME, everybody must agree on changes to standards. So, when changes are introduced, proponents of the change provide supporting data, answer questions posed about the data, educate committee members if needed, and otherwise try to move the process along. The researchers working on the Alloy 617 Code inclusion started with the high temperature working group. After clearing that hurdle, the next stage involved doing the same for the appropriate subgroup, followed finally by achieving consensus from the full committee. Volunteers from industry, national laboratories and elsewhere serve on the various working groups, subgroups and committees, which meet to consider changes to the standards four times a year.

“We started moving it through the balloting process. It took three full years,” Wright said. The final approval came in the fall of 2019.

The last new high temperature material had been added to the Code in the 1990s, and that partially explains why getting approval took so long, he said. “A big challenge for us was simply reinvigorating this process that hadn’t been used in 30 years.”

The entire Alloy 617 project took 12 years to complete at a cost to the Department of Energy of $15 million. Adding prior work and non-DOE contributions, brought the total material research expenses into the tens of millions of dollars and decades of time.

Now that Alloy 617 is part of the engineering toolkit, designers of high temperature nuclear plants have a new material that offers an expanded operating range. The previously allowed high temperature materials could not be used above about 750o C (around 1,380o F), according to Wright.

“Our newly qualified material can be used in design and construction up to 950o C [about 1,750o F]. As a result, it could enable new higher temperature concepts,” he said.

If that happens, it’ll be another example, as was the case with the three little pigs fable, that constructing things with the right material is a critical building block for success.