Systems Engineering & Integration

About

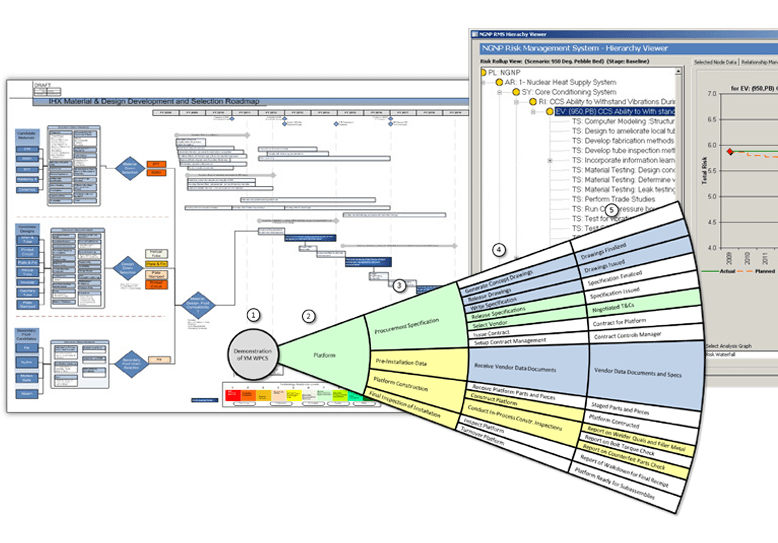

Systems Analyses and Integration (SA&I) develops innovative solutions to a wide range of complex challenges. Its unique mix of mission analysis, requirements management, integration, decision analysis, and roadmapping expertise ensures:

- Customer needs are understood and project requirements are identified and validated throughout the project life cycle

- Viable solutions are developed and integrated to satisfy expectations

- Potential impacts of technical and program risk are minimized

SA&I delivers independent, objective results to ensure a system-wide perspective is considered for use in establishing budgets, planning and executing projects, and increasing the probability of project success.

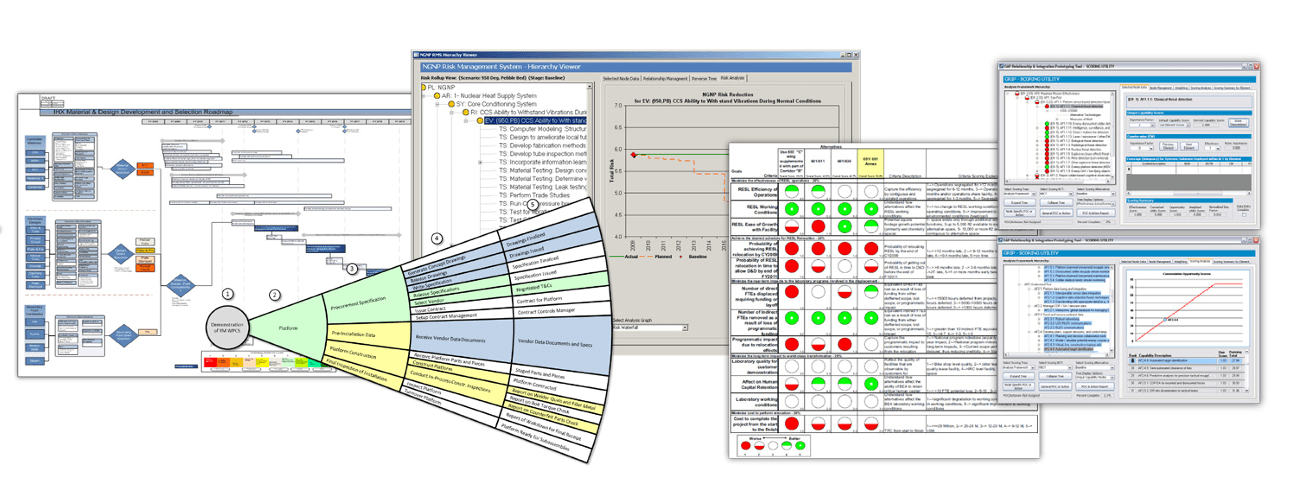

Core Functions

SA&I has decades of combined experience applying systems principles in the DOE, DOD, NASA, and private sector. The seven core SA&I functions applied at the INL provide the structured approach and technical analyses necessary to ensure the systematic, risk-informed management of R&D, programmatic, and operations activities.

The seven core functions are:

- Mission Analysis & Planning

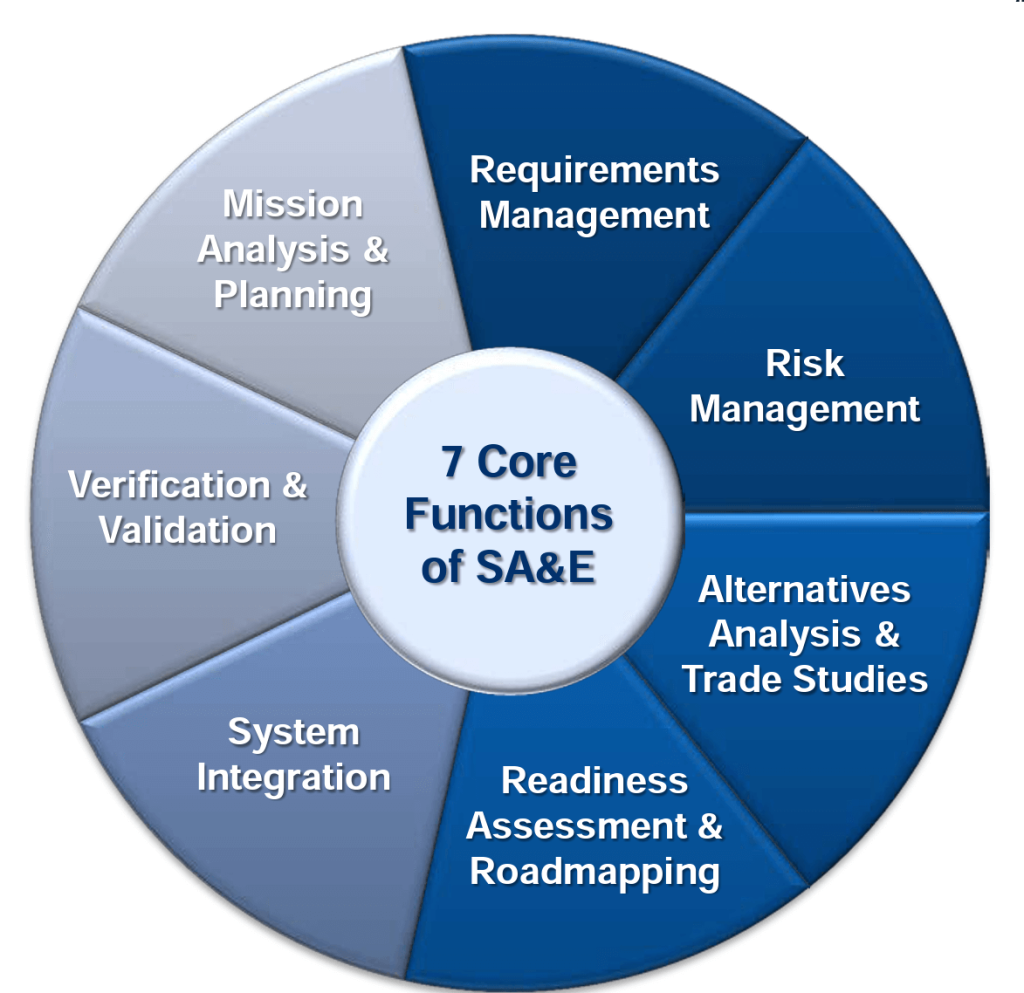

- Requirements Management

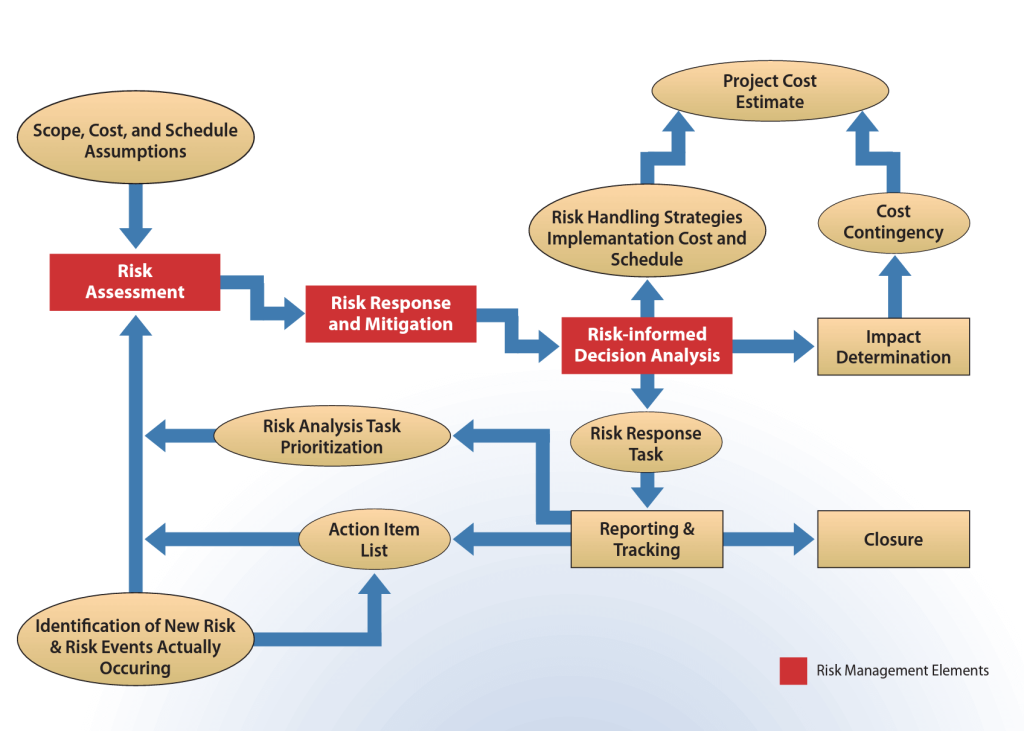

- Risk Management

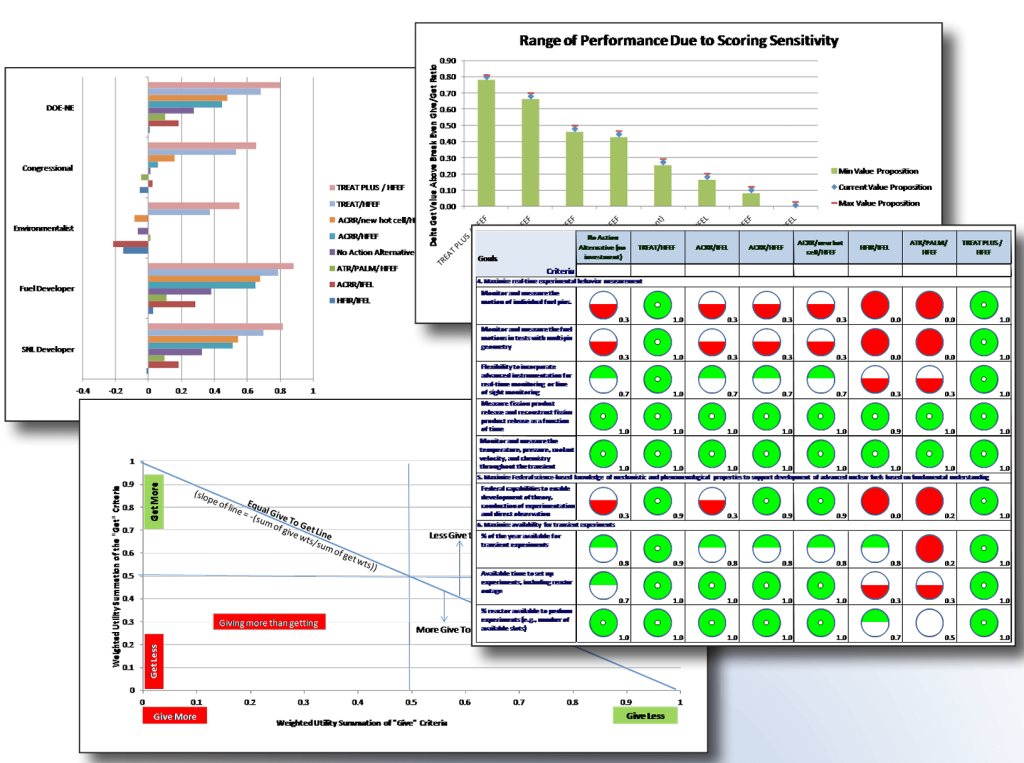

- Alternatives Analysis & Trade Studies

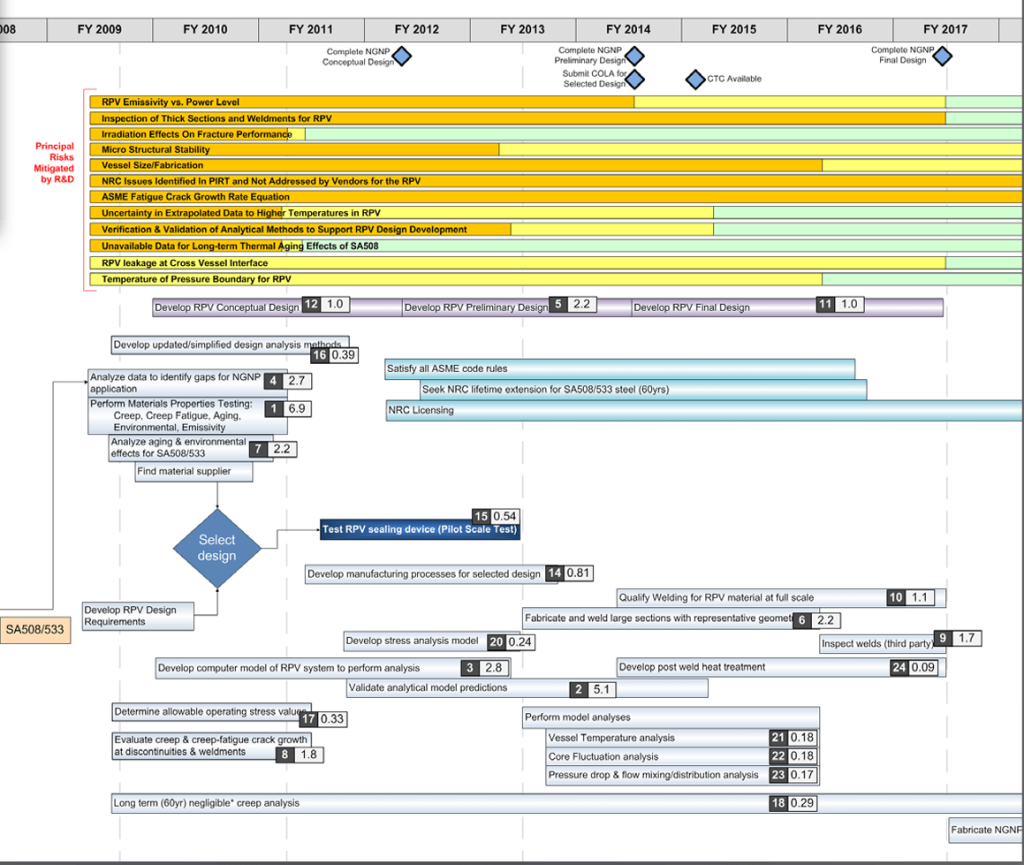

- Technology Readiness Assessment & Roadmapping

- Systems Integration

- Verification & Validation

Benefits

The application of SA&I functions offers several benefits for INL projects, R&D activities, and operations, such as:

- Clear understanding of customer challenges and requirements

- Analysis and down-selection of preferred solution(s)

- Improved integration and collaboration

- Focused R&D toward technology maturity

- Basis for defensible, risk-informed decisions

- A higher probability of overall project success

Factsheets

SE Core Functions

Mission Analysis & Planning

Requirements Management

Risk Management

Alternatives Analysis & Trade Studies

Technology Readiness Assessment

Systems Analysis & Engineering

Innovative Systems Engineering

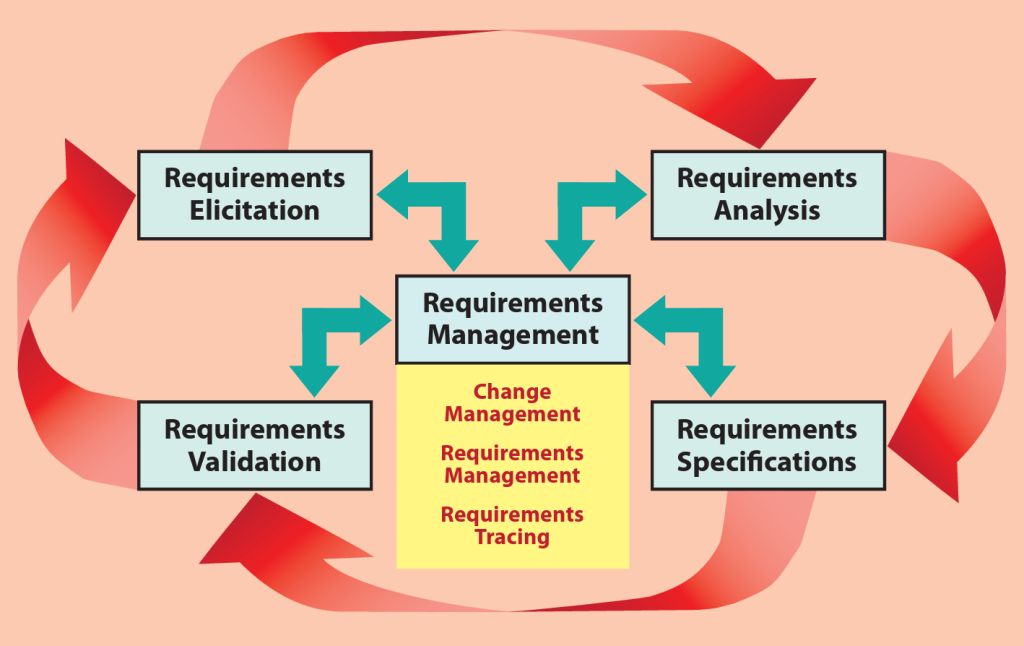

Computer-Aided Decision Support

Team & Organization

James Case

Senior Manager

Humberto Garcia

Senior Advisor

Kevin Kenney

Radioactive Source Recovery RM

Justin Welch

IROC Operations Director

Michael Darby

Systems Engineering Team Lead

Kurt Meyers

Energy & Grid Systems Integration Team Lead

Pam Crane

Radioactive Material Disposition & Security Team Lead