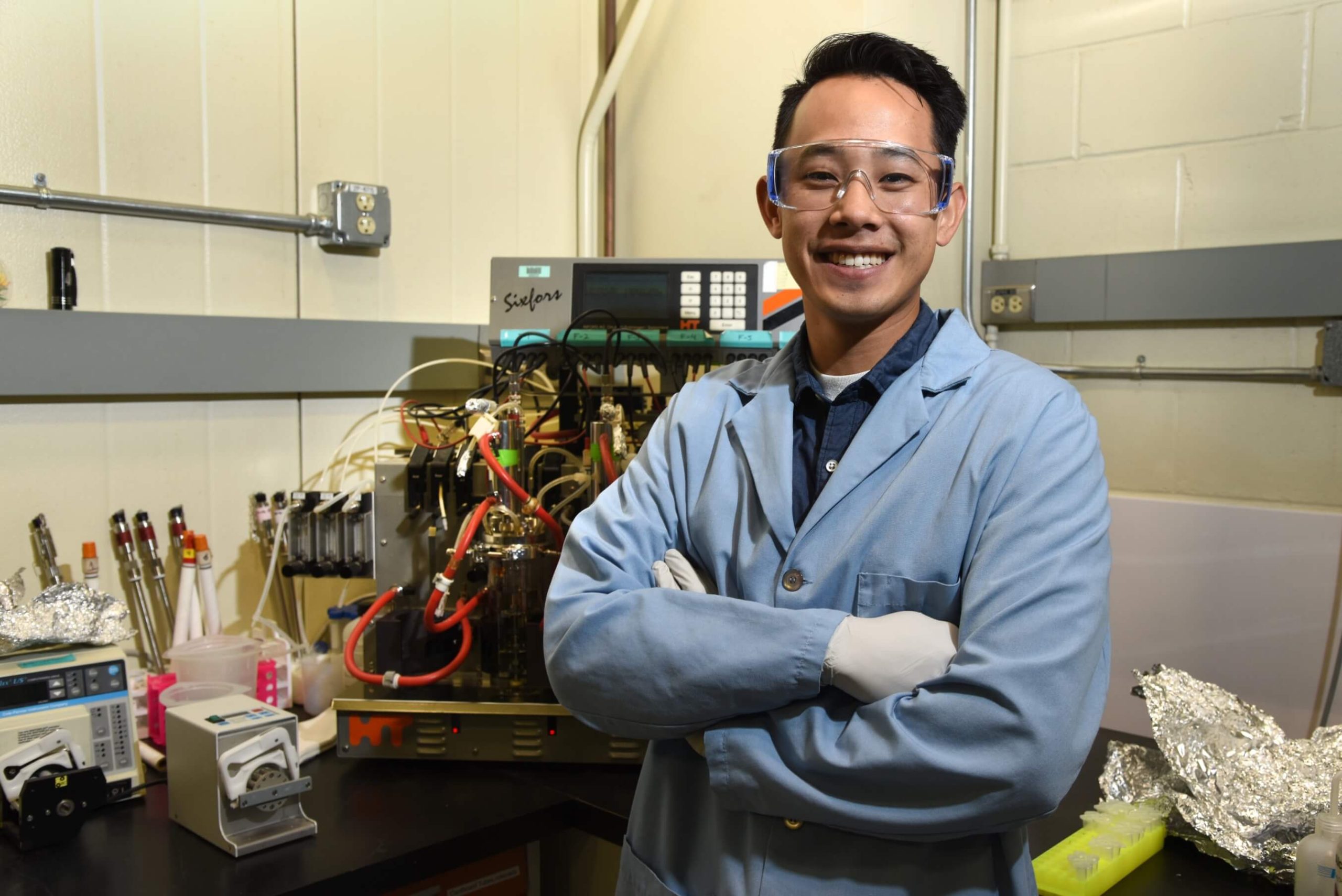

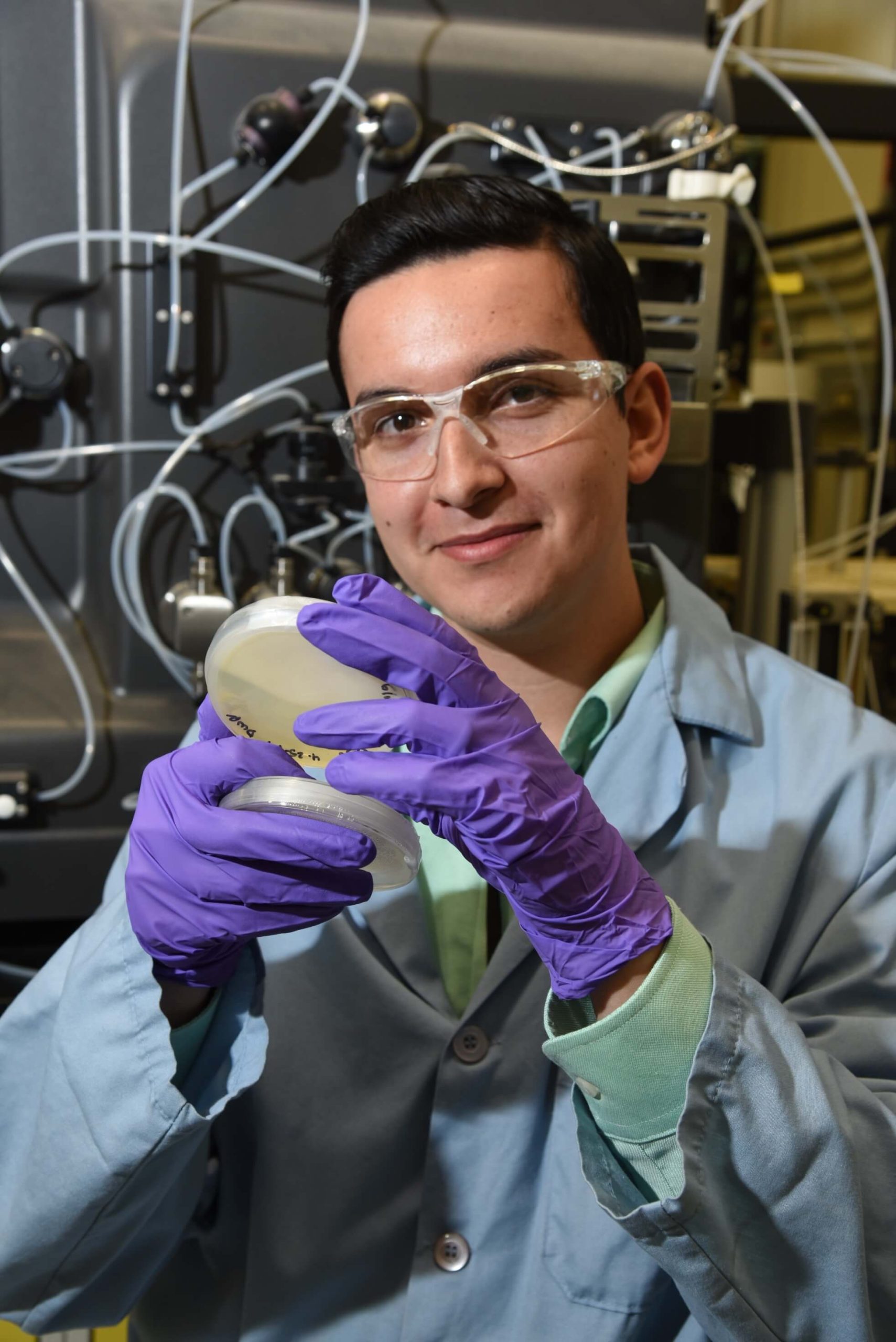

In an Idaho Falls laboratory, interns Matthew Yim and Michael Crain-Zamora tinker with complicated glass and metal vessels used to grow Gluconobacter oxydans, a bacterium that causes fruit to rot.

Growing the bacterium is tricky business. All of the lab equipment is sterilized to prevent contamination, and an array of probes monitors the growth of the microorganism. The microbe feeds on a mixture of sugar and salts, and the conditions need to be just right or the bacteria won’t flourish. “If the oxygen level goes too low, then jumps back up again, it can be hard on the microbe’s growth,” says Yim.

The outgoing seniors from Brigham Young University-Idaho are participating in the prestigious Science Undergraduate Laboratory Internship program. For their internships, Yim and Crain-Zamora are helping Idaho National Laboratory researchers tackle one of the biggest problems facing today’s high-tech industry: recycling metals such as neodymium and dysprosium.

If you’ve never heard of neodymium and dysprosium, you’re probably not alone. But chances are, you and nearly every other working-age adult in the United States has a small amount of these metals in your pocket.

That’s because these so-called “rare earth elements” are key components for cellular phones, among many other high-tech devices.

Lanthanum, for example, is used in hybrid car batteries, fiber optics, electron microscopes, telescope lenses, petroleum cracking catalysts, steel manufacturing, swimming pool cleaning products and medications. Other rare earth elements are found in everything from computers to lights to wind turbines.

The problem with rare earth elements, as their name suggests, is that they’re not often found in economically exploitable ore deposits.

They’re also very difficult to recycle from, say, used cellphones. Conventional techniques used to recover rare earth elements from recycled materials and ores may involve high heat, high pressures and harsh chemicals. Furthermore, the process is expensive and is not very efficient.

To overcome these challenges, INL researchers have developed a technique that uses the bacterium Gluconobacter oxydans to recover the metals—a process called “bioleaching.” Gluconobacter produces a mix of chemicals that contains organic acids such as gluconic acid, which can help extract rare earth elements from materials such as ground up magnets.

So why bother with bacteria? Why not just use organic acids produced in a factory? It turns out that the mix of chemicals produced by the bacteria works better than organic acids alone. The bacteria are probably producing something else—researchers aren’t sure what—that helps the bioleaching process.

The technique has the added benefit of being easy on the environment.

“Anything we’re producing is organic, so to speak,” says David Reed, an INL research scientist. “It’s biodegradable. It’s not corrosive. It’s not hazardous. It’s green technology.”

And the technology works, at least in the laboratory. Yim is helping advance the technology to an industrial scale.

“We’ve been extracting less-than-a-gram amounts, and now we want to improve that to kilogram and tonne amounts,” Reed says.

Crain-Zamora is researching cheaper methods to grow the bacteria. “We’re able to get Gluconobacter to grow very well when we give it some glucose (a simple sugar),” he said. “We’re looking for less expensive options such as waste products from agriculture like corn stover and sugar beet pulp. When you harvest these crops and recover the grain or sugar, you’re left residues. We can break the residues into simple sugars that Gluconobacter can eat.”

Using inexpensive, readily available wastes to grow the bacteria will in turn lower costs, making bioleaching more attractive to industry.

The idea has already drawn some interest. One company, a recycler of mercury from fluorescent lightbulbs, has provided Reed and his team with phosphor powders recovered from those bulbs. Bioleaching could be used to recycle rare earth elements from the light phosphors. Another has provided computer parts for testing.

Yim is examining the recovery of rare earth elements from petroleum-cracking catalysts, which are used to refine crude oils into products like gasoline.

Reed thinks bioleaching could also help the mining industry extract rare earth elements and other desirable metals from mining waste materials. Bacteria and nutrients would be introduced to low-grade material to collect trace amounts of metals that might otherwise be too difficult to recover.

“Maybe we can make it economical for them,” Reed says.