Selective Separations and Recovery

Critical Materials

Revolutionizing Critical Mineral Extraction

The Sequential Separations and Selective Recovery pillar is dedicated to modernizing the production of critical and strategic materials through advanced chemical and isotopic separation techniques. By optimizing processes from chemical leaching to the delivery of high-purity metals and oxides, we strive to reduce waste, energy consumption, and environmental impact. Our focus is on developing efficient, clean production methods that maximize resource recovery and support the sustainable supply chain for critical materials.

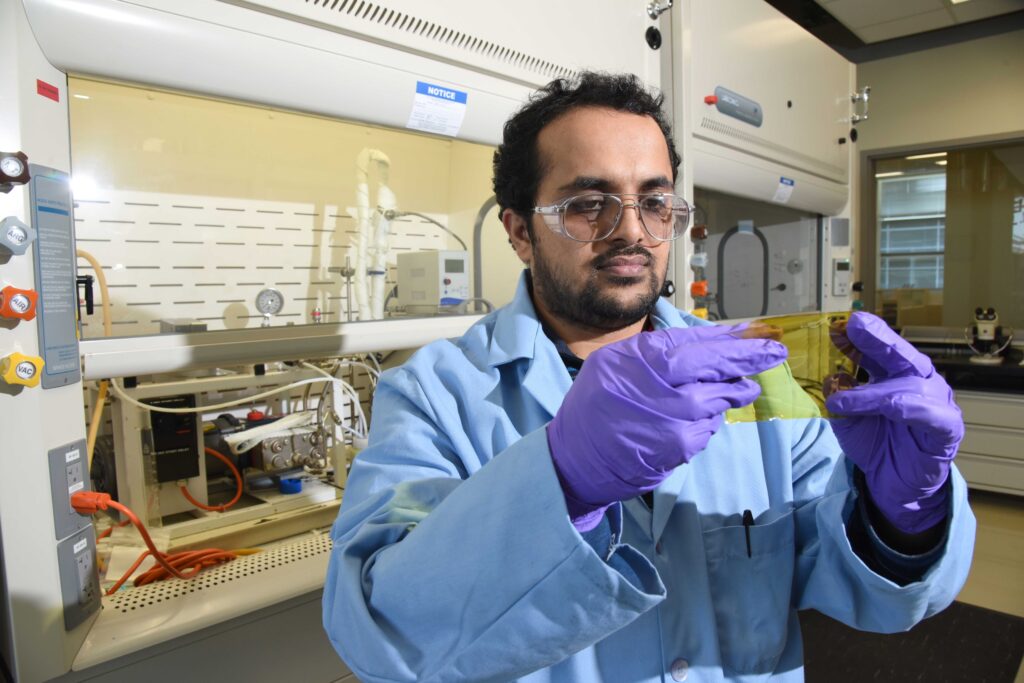

Hydrometallurgy

Hydrometallurgy is a liquid-liquid separation process to purify target metals from a complex matrix of undesirable contaminants.

It can be achieved through solvent extraction techniques using a variety of equipment and chemical separation flowsheets. Capabilities include the collection of experimental chemical equilibrium data for complex multicomponent systems, computational modeling and simulation for flowsheet design, and validation within counter-current solvent extraction systems. Among those capabilities are:

A wide range of separations equipment specific to solvent extraction operations, including mixer settlers, pulsed columns and centrifugal contactors

Development and testing of multi-stage, counter-current engineering flowsheets using a variety of small laboratory systems that can inform flowsheet design and scale-up

In addition, the laboratory brings expertise in chemistry and separations of rare earth elements, actinides and other metal ions.

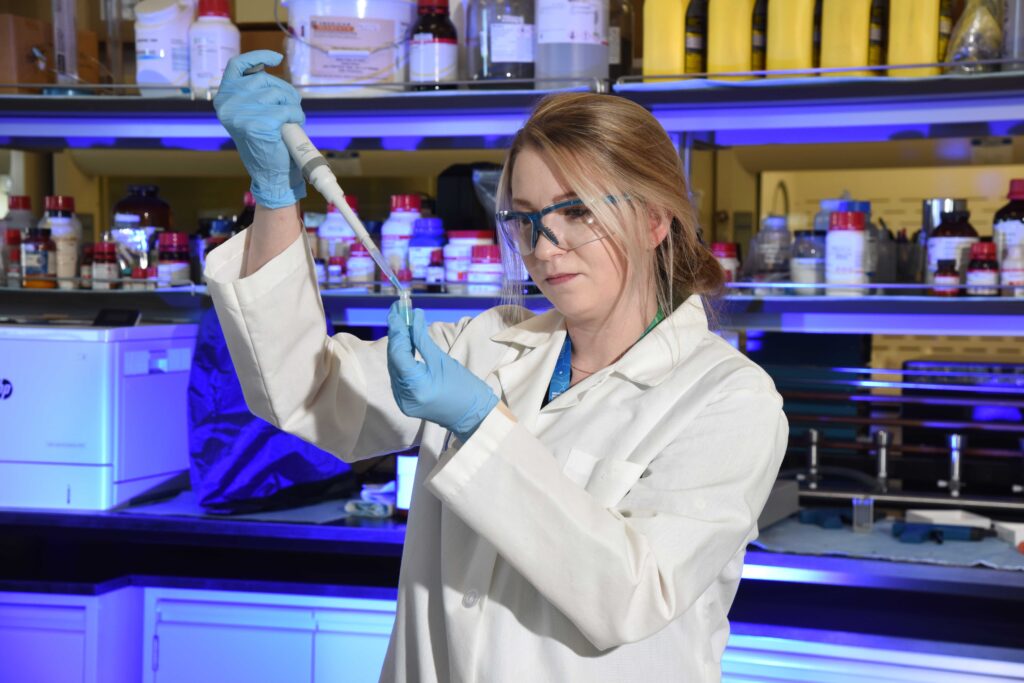

Biohydrometallurgy

Bioleaching uses acids or metabolites to solubilize and release metals from a solid matrix, which may be ores or unconventional materials.

Bioleaching may rely on microbial reduction-oxidation reactions of iron and oxidation of sulfidic minerals to produce sulfuric acid, or it may rely on the bioproduction of acidic and/or chelating metabolites, such as organic acids. INL develops processes that use both mechanisms to recover critical metals (e.g., rare earth elements, lithium, cobalt, tellurium) from a variety of resources (e.g., ores, tailings, fluidized catalytic cracking catalyst wastes, phosphor wastes, phosphogypsum, permanent magnet wastes, lithium-ion battery black mass).

Process development is aided by thermodynamic modeling and multi-omic techniques to identify microbial communities, metabolites and proteins responsible for efficient mineral recovery. Fundamental understanding of the mechanisms involved enables the identification of critical process variables. Optimization of the process variables can then be guided by design of experiment modeling, where the targets for the latter are determined by technoeconomic assessment and life cycle analysis. The goal is to develop economically competitive and environmentally responsible approaches for critical mineral recovery.

In addition, the multi-omic results enable the development of techniques to monitor performance.

Electrochemical Facilited Hydrometallurgy

INL applies innovative electrochemical concepts to develop scalable critical material recovery technologies, substituting intensive chemical consumption with electrons as main oxidation and/or reduction reagents. Applications of electrochemical approach include extraction of valuable and critical materials from electronic waste, end of life lithium-ion batteries, solar panels, and waste reduction in ore extraction. Further capabilities being developed at the lab are electrophoretic transport-based rare earth elements separation.

Membrane Facilitated Separations

Membranes are used in the separation of elements, including critical materials, by taking advantage of molecular size exclusion and solubility preferences. INL has been involved in membrane development and testing for more than 40 years. This work includes gas-phase separations, liquid phase separations and pervaporation (liquid to gas phase).

The laboratory specializes in high-performance polymer membranes and engineered nano-scale materials. Among them are:

- Polymer membranes for selective gas separations of CO2, hydrogen and oxygen separations

- High temperature polymer membranes to separate hydrogen from CO2 (syngas)

- Membranes that use pervaporation and membrane distillation for organic and aqueous solutions

The laboratory also researched water filtration with membranes (nanofiltration, forward osmosis and reverse osmosis), as well as facilitated transport membranes for the separation of ethylene from alkanes (saturated hydrocarbon gases).

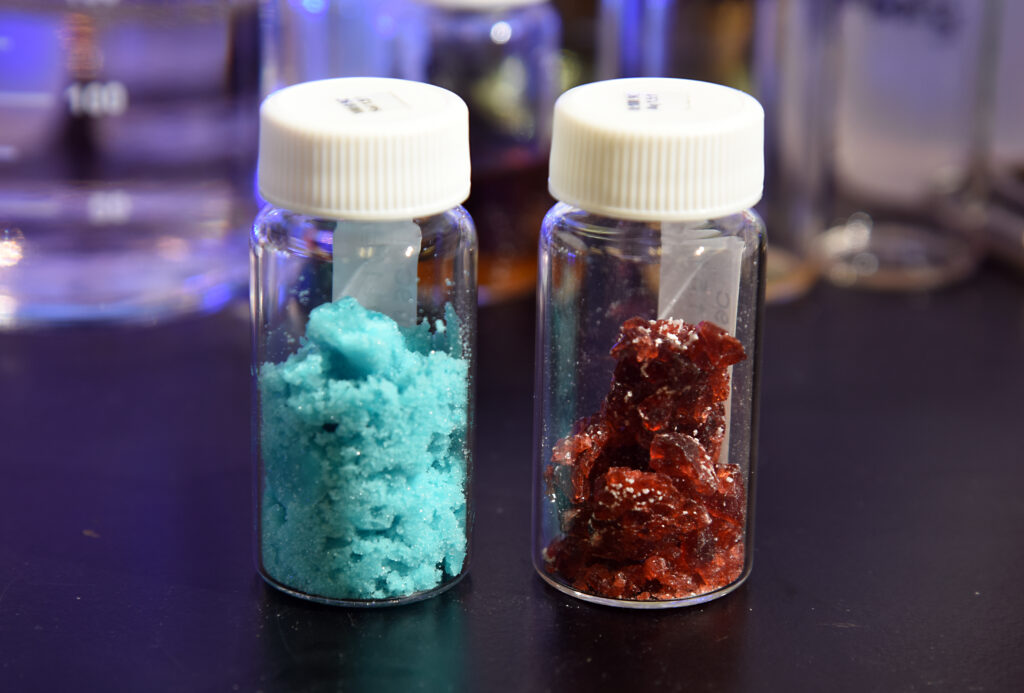

Fractional Crystallization

One focus area is dimethyl ether-driven separations, which remove solids from solutions and solutions from solids. They are accomplished with high selectivity (separation factors as high as 700), low energy cost and much higher energy efficiency compared to state-of-the-art processes, while also avoiding the waste generation of chemical (including base) precipitation. The processes are facilitated by dimethyl ether, a low-cost, low-toxicity, environmentally benign commodity chemical that can be easily recycled (>99.9995%). Application space includes mineral recovery, water treatment and processing of wet solids.

Electrochemical Facilitated Separations in Molten Salt

Molten salt media are used instead of aqueous media for electrodeposition of metals due to their wide electrochemical stability window, high ionic conductivity and fast electrodeposition kinetics. Important metals like aluminum and rare earth metals are thus produced this way. At INL we’re investigating novel extraction and electrodeposition methods in molten salts that reduce cost, increase efficiency and replace complex separations and toxic chemicals with an electricity-driven processes that use common, non-toxic salts.

Chemical Separations

In mineral processing, the initial step after mining includes physical beneficiation, a process during which the concentrated fractions of the element (or elements) of interest are obtained. Then, metals can be brought into an aqueous medium through hydrometallurgical processes.

INL developed an efficient solution to unlock one of the largest cobalt reserves in the U.S. This novel method extracts cobalt from minerals like cobaltite, which also contains the toxic element arsenic. Through an energy-efficient, low-temperature electrochemical process, arsenic is separated and immobilized as an inert mineral (scorodite).

The environmental hazards associated with groundwater contamination are thus eliminated, unlocking the potential value of cobaltite minerals.

Work With Us

Need more information about our capabilities or research? Want to work with our experts?