The U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) has awarded more than $5.8 million to Idaho National Laboratory to support research that boosts domestic supplies of the critical elements needed to meet the nation’s clean energy goals.

The money comes through two ARPA-E programs. The first, Mining Innovations for Negative Emissions Resource Recovery, or MINER, is for developing commercially scalable technologies to increase domestic production of rare earth elements and critical minerals such as copper, nickel, lithium and cobalt. The second, Converting UNF Radioisotopes into Energy, or CURIE, sponsors projects led by universities, private companies and national laboratories that develop new reprocessing technologies for extracting and recycling valuable actinides from used nuclear fuel.

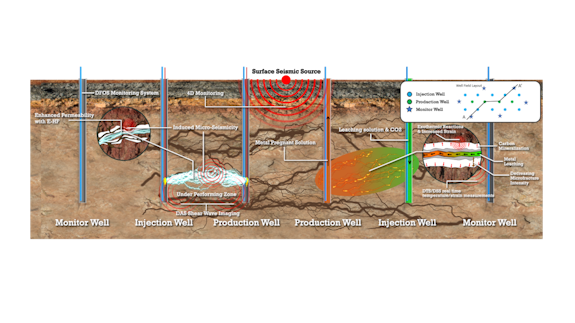

Through MINER, ARPA-E has awarded $3.1 million to an INL project led by Wencheng Jin. The project will develop a disruptive technology called electric-hydraulic fracturing to break up underground rock deposits, extract critical minerals and sequester carbon dioxide. Weakening rock before mining reduces water consumption and requires less crushing, grinding and tailings.

Under CURIE, INL is slated to receive nearly $2.7 million for work focused on using electricity to recycle nuclear fuel led by Prabhat Tripathy. Specifically, the lab will design, fabricate and test anode materials for electrochemically recovering radioactive elements from used nuclear fuel for use in advanced reactors. These actinides — elements such as uranium, thorium and plutonium that release energy during radioactive decay — can be used to power the next generation of nuclear reactors.

MINER: Better extraction through electricity, chemistry

MINER’s intent, according to ARPA-E’s funding announcement, is to develop technologies that will help achieve carbon-negative mining operations.

Certain ore deposits contain strategic minerals such as nickel, copper, cobalt and platinum, critical for energy transition. They also contain minerals such as olivine, a magnesium iron silicate that reacts with carbon dioxide. The biggest challenge to mine these minerals and isolate carbon dioxide is the lack of reactive surfaces. Using electrical current and fluids, Jin and his collaborators – Eden Geopower, Colorado School of Mines and Stony Brook University – aim to fracture ore deposits then inject enhanced metal leachate charged with carbon dioxide. While the leachate creates conditions for minerals to be extracted the carbon dioxide will be trapped on the surfaces of the fractured rock. Experimental and numerical simulations indicate this can increase permeability up to 500%, leading to recovery of up to 80% of the energy-relevant minerals and mineralizing up to 60% of the injected carbon dioxide — a vital carbon capture goal.

“With carbon negative mining, energy used to extract the minerals is far less than what is used in open pit or underground mining,” Jin said.

Eden Geopower has performed a preliminary field test and Colorado School of Mines continues to develop a technology called distributed fiber-optic sensing, to monitor fracture processes and chemical reactions during operations. The first full-scale field tests will be done at the Sanford Underground Research Facility, a laboratory in South Dakota that houses dozens of experiments in geology, biology, engineering and physics.

CURIE: Stronger, less expensive anodes

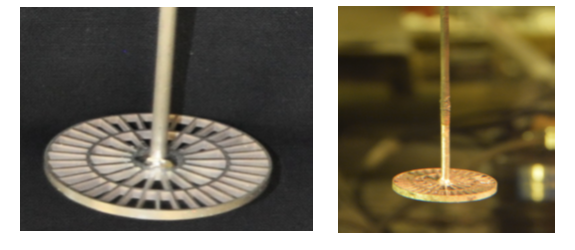

Pyroprocessing uses electricity and chemicals to recover actinides like plutonium and uranium from used nuclear fuel. The anodes used in this process have traditionally been made from either platinum or graphite. In addition to being expensive, these materials degrade rapidly, contaminating the metallic product and increasing the carbon footprint. Researchers have long been looking for an anode that can maintain its structural integrity during pyroprocessing.

To reduce anode costs and improve performance, Tripathy and his research team aim to fabricate new anodes made from iridium and ruthenium and evaluate their performance for commercial use. Developing robust anode materials supports a transformative solution to treating used nuclear fuel without generating greenhouse gases, Tripathy said.

The work expands on research Tripathy has conducted at INL and Massachusetts Institute of Technology. Because iridium belongs to the same group of metals as platinum, Tripathy fabricated anodes and performed experiments at engineering scale using kilogram quantities of spent nuclear fuel oxides, rare earth metals and alloys commonly found in devices such as smartphones, laptops and electric vehicles. In his experiments, the monolithic iridium anodes experienced continuously extreme conditions for days at a time yet demonstrated service life nearly 10 times longer than platinum anodes under identical stress.

When iridium’s price nearly quadrupled around 2020, Tripathy turned his attention to ruthenium, a more affordable metal from the same family of elements. While he has tested monolithic ruthenium at bench scale for depleted uranium oxide and non-nuclear oxides, under CURIE these anodes are to be tested for actual spent fuels. Anodes made of alloys containing ruthenium and iridium and iridium/ruthenium-coated anodes will also be fabricated and tested. Outside of used nuclear fuel, Tripathy says the technology could be used to recover rare earth metals from e-wastes and remove toxic elements involved in environmental remediation work.

Supporting university, industrial research

In addition to these two projects, INL researchers can take part in four other ARPA-E/CURIE projects for two universities and two private companies. Here is what they involve:

- Self-powered Wireless Hybrid Density/Level Sensing with Differential Pressure Sensors for Safeguarding and Monitoring of Electrochemical Processing of Nuclear Spent Fuel — INL’s Guoping Cao is working with Haifeng Zhang of the University of North Texas.

- Achieving 1% Isotopic Assay of Special Nuclear Materials in 2 Minutes with Microcalorimeter-Array Gamma-Ray Spectroscopy — INL’s Ammon Williams is partnered with Daniel Becker of the University of Colorado.

- Closing the Cycle with NuCycle — INL’s Ken Marsden is consulting with Vik Singh of Curio Solutions.

- Improved Volatile and Semi-volatile Radionuclide Off-Gas Management — INL’s Amy Welty is working with Phillip Cox of Mainstream Engineering.

About Idaho National Laboratory

Battelle Energy Alliance manages INL for the U.S. Department of Energy’s Office of Nuclear Energy. INL is the nation’s center for nuclear energy research and development, and also performs research in each of DOE’s strategic goal areas: energy, national security, science and the environment. For more information, visit www.inl.gov. Follow us on social media: Twitter, Facebook, Instagram and LinkedIn.

Published on Jan. 26, 2023.

By Paul Menser, INL Communications