Hydropower is a reliable source of energy. However, the inconsistent nature of water flows and electricity demand often challenges hydropower operators and reduces revenue.

To address these challenges, the Idaho National Laboratory (INL) and Pacific Northwest National Laboratory (PNNL) partnered with Idaho Power, which operates 17 hydroelectric projects, to analyze the economic and environmental impacts of integrating hydrogen production with hydropower plants. The project, funded by the Department of Energy’s Water Power Technology Office, aims to increase the revenue of hydropower plants.

There are two main types of hydropower plants: run-of-river and impoundment. Both types can be integrated with hydrogen production.

Run-of-river plants generate electricity based on the flow of the river, without the ability to store water for extended duration. However, their power output fluctuates with the river’s flow, which changes throughout the year. Impoundment plants can store and release water as needed to meet seasonal energy and water demands. These reservoirs often provide recreational opportunities as well.

Hydropower challenges

Both run-of-river and impoundment plants are less profitable during times of low demand.

“Especially in the spring, there are times when there’s a lot of water flow that can be used for hydropower generation, but the power demand is low and power generation isn’t particularly profitable,” said Dan Wendt, a chemical engineer at INL and the principal investigator on the study.

Although impoundment plants can store water, operators are still required to release it based on the plant’s Federal Energy Regulatory Commission license or other regulatory requirements, even if they aren’t generating power and profit.

“We have to let a certain amount of water go downstream to support environmental objectives like fish migration, water quality improvement and managing water supplies during a drought,” said Fred Noland, an environmental manager for recreation and public access at Idaho Power. “There are a lot of challenges, but they’re not insurmountable.”

Another challenge for impoundment hydropower operators is maintaining downstream oxygen levels. Reservoirs and dams can reduce downstream oxygen levels, negatively impacting aquatic life.

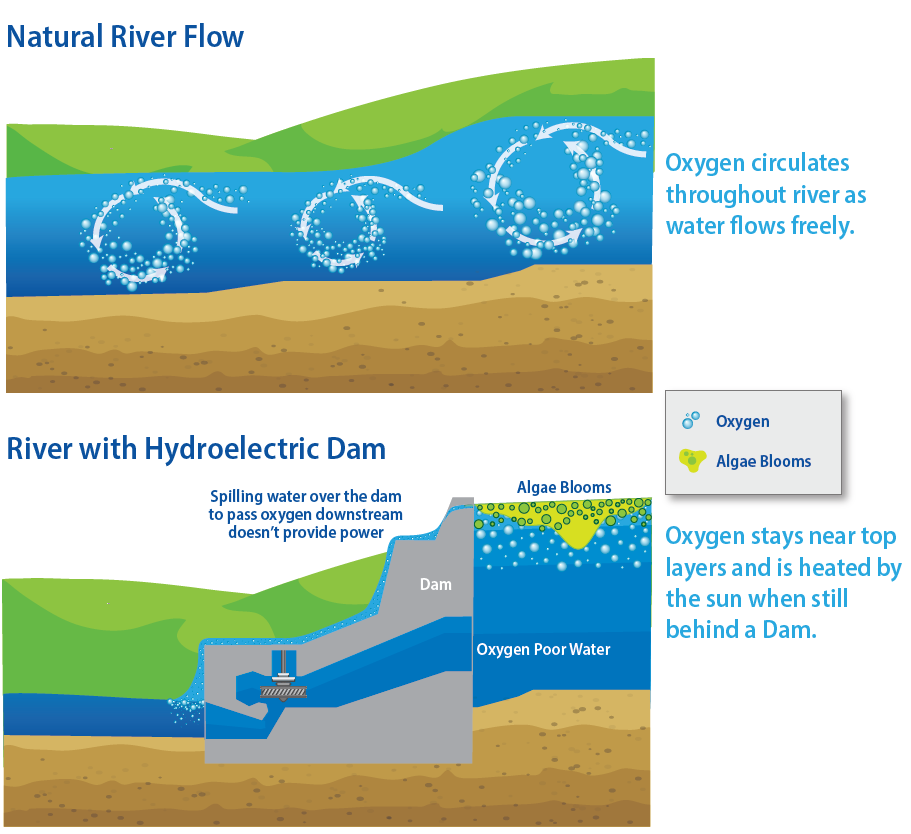

Normally, as a river flows, the water tumbles and mixes, distributing oxygen throughout. When water is trapped behind a dam, it forms layers. The top layer is heated by the sun and the warmer water stays near the top, while the bottom layer remains cooler and oxygen-poor.

Water downstream from the dam can suffer from low oxygen when water is released from the reservoir’s oxygen-poor layer. To mitigate this, hydropower plants use special equipment or operational techniques, such as spilling water over the dam or turbine venting, which reduce water available for power generation.

Hydrogen integration offers solutions

Hydrogen production could keep hydroelectric plants operating at near maximum capacity, and profitability, even during periods of low demand. Instead of letting water flow through the dam without generating electricity or producing power that is sold at low prices, operators could use energy to produce hydrogen.

The project team used advanced modeling and analytical methods to explore deployment scenarios that would maximize the benefits of hydrogen integration. Researchers evaluated various case studies for Idaho Power to determine the best system configurations, operating modes and hydrogen use applications for their developing hydrogen strategy.

Hydrogen has multiple uses. Primarily, hydrogen is valuable for transportation fuels and the production of fertilizers, metal, pharmaceuticals, silicon chips and glass. It is used to refine petroleum into gasoline and diesel and to extend the shelf life of foods.

“If the hydropower plant were integrated with a hydrogen production facility, they could store the clean hydrogen for power generation when the demand is high or sell the hydrogen into a chemical or transportation fuel market where the pricing is more consistent,” Wendt said.

Hydrogen can also be banked and turned back into electricity when demand exceeds what the plant can produce. By using hydropower and hydrogen generation in tandem, Idaho Power could provide more support to the grid and increase revenue.

“Adding hydrogen enhances grid stability and creates a more flexible power plant,” Wendt said.

Oxygen, a byproduct of hydrogen production, can be added to the water as it flows through the power plant, which may be more cost effective than other oxygenation methods.

By producing hydrogen, Idaho Power could harness hydropower to improve power production and open new sources of revenue. Hydrogen production potentially increases revenue during low energy demand, and the oxygen byproduct can improve water quality.

“One of the things I think it’s important to pull from this is that sometimes you do the research and exploration, and it isn’t the right time or ‘no’ is the answer,” said Noland, who led a strategy council team to create a hydrogen roadmap for Idaho Power. “INL and PNNL were able to connect data and information for it to be spatially and temporally valuable. It helped us understand the market and what would be needed.”