Center for Radiation Chemistry Research

Capabilities

Energy Innovation Center Irradiation Suite

Many of these capabilities can be integrated using the FTS Model-812 irradiator’s two access ports to provide in-situ/in-line and real-time monitoring. A prime example of this integration is one of our new capabilities for performing high temperature (≤ 200 °C) in-situ gamma irradiations of aqueous solutions with spectroscopic monitoring.

The bespoke titanium cell has sapphire windows that can be interfaced with a spectrophotometer via coupled fiber optics cables and collimating lenses to collect absorbance data in real-time during irradiations.

Jacy Conrad using her high-temperature cell to study radiation-induced chromium redox chemistry.

The Model-812 irradiator is also part of the Nuclear Science User Facility’s (NSUF) suite of reactors, hot cells, beamlines, and analysis instrumentation. As such, our instrument can be made available for the exploration of basic and applied nuclear research via their funding opportunities.

In addition to our gamma irradiation capabilities, the Energy Innovation Laboratory Irradiation Suite now has an adjoined laser flash photolysis laboratory, which currently houses a Luzchem LFP-412/422 laser photolysis transient absorption and diffuse reflectance spectrometer. The Luzchem LFP-412/422 utilizes a 10 Hz Continuum Surelite I-10 Nd:YAG laser (512 nm, 355 nm, and 266 nm outputs) as the excitation source and a 300 W continuous wave xenon lamp to determine the transient absorption spectrum. The laser and xenon are coupled to the sample cell using fiber optics. Transient species with lifetimes of > 10 nsec – seconds may be monitored with this system. A temperature-controlled flow-thru sample cell is available for temperature and light sensitive samples.

Materials and Fuels Complex Irradiation Suite

Located in the Fuels and Applied Science Building, the Materials and Fuels Complex Irradiation Suite offers access to a MDS Nordion Gammacell 220 Excel cobalt-60 gamma irradiator directly supported by an Agilent Cary 6000 UV-Vis-NIR spectrophotometer, a bank of CINC V-02 centrifugal contactors, and compressed gas cylinders regulated by an array of Sierra Instruments mass flow controllers for inline sparging.

The Nordion Gammcell consists of an annular source permanently enclosed within a lead shield, a cylindrical drawer, and a drive mechanism to move the drawer up or down along the source center-line. The drawer has a chamber to carry samples to be irradiated from outside the shield to the source. Samples up to approximately six inches in diameter and eight inches in height can be accommodated in the chamber. Liquid, gaseous, electrical, or mechanical connections can be introduced into the sample chamber through an access tube in the upper portion of the drawer. An electrically powered digital timer automatically raises the drawer at the termination of a sample irradiation. The Nordion Gammcell—also available via the NSUF —is reserved for low-dose rate (~30 Gy min–1) irradiations and provides the niche capacity to irradiate radioisotope containing systems, such as aqueous acidic solutions of the actinides. Additionally, this instrument supports the use of a bespoke test loop. This unique capability was developed to evaluate the radiolytic stability and performance of advanced solvent systems for used nuclear reprocessing under conditions more representative of industry. The INL test loop is made up of an irradiated volume contained in a borosilicate glass coil (∼75 feet in length, 0.375 inch outer diameter, 0.202 inch inner diameter), and an external stainless steel manifold, composed of a magnetic drive gear pump and a second stainless steel coil held in a temperature-controlled water bath to maintain loop solvent temperature.

A second test loop has been designed to eliminate components located outside of the gamma irradiation sample chamber, thus increasing the effective gamma dose rate delivered to the solvent system under test. While the original test loop pumped the aqueous and organic phases through a glass coil held in the irradiator sample chamber, the new design uses a single vessel. Mixing of the aqueous and organic phases during irradiation is accomplished using an air-driven magnetic stirring plate to mix the phases held in the irradiation vessel. Temperature control is provided by a cold finger held in the center of the irradiation vessel. The cold finger is connected to an external temperature-controlled water bath.

The Materials and Fuels Complex Irradiation Suite is also supported by the INL Radiochemistry Laboratory, a state-of-the-art radiological facility that provides extensive handling—eight active fume hoods, two air gloveboxes, and one argon glovebox—and analytical capabilities for the preparation, characterization, and post-irradiation examination of radionuclide containing solutions.

Theory and Modeling

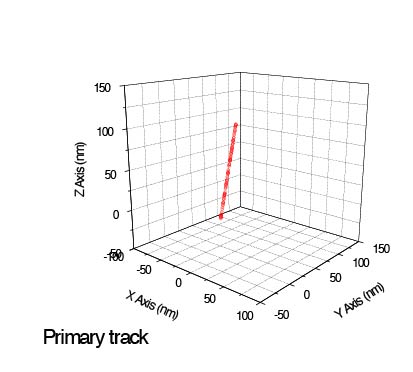

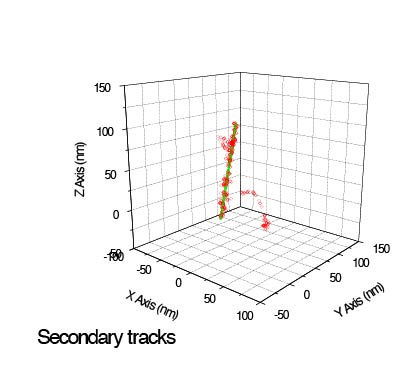

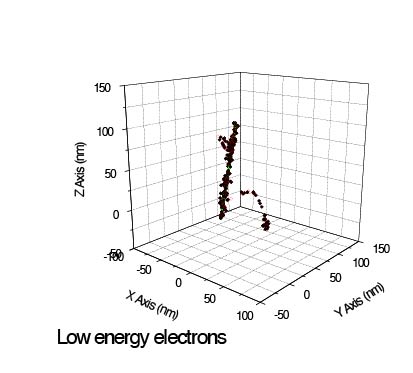

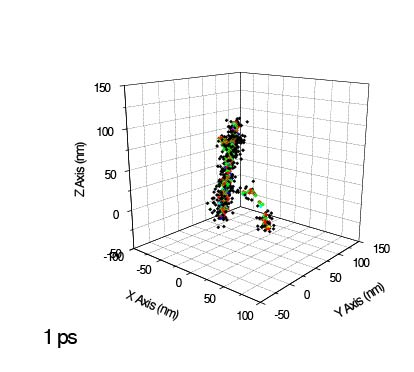

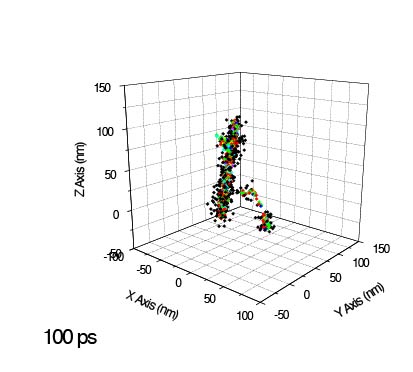

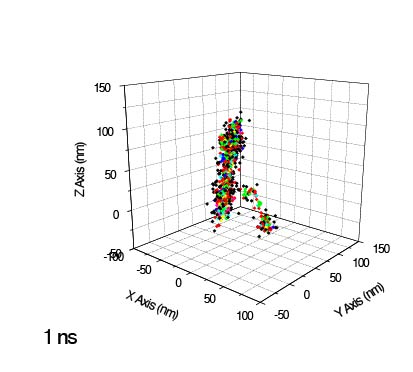

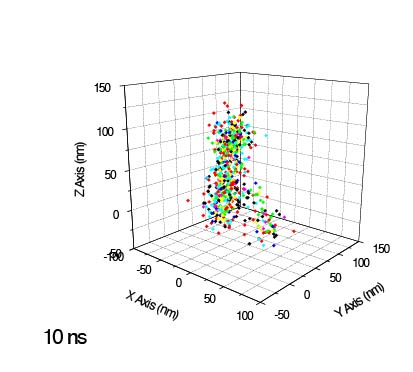

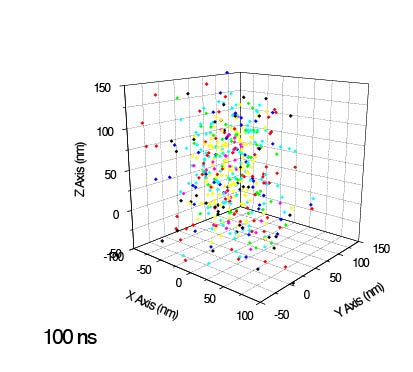

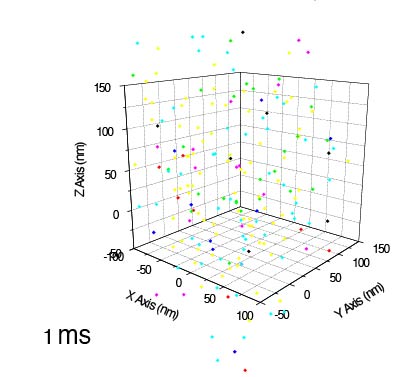

Simulated 5 MeV helium ion track chemistry in water.

In addition to experimental capabilities, the INL CR2 is also actively involved in the development of complementary theory and modeling methods for irradiated systems, specifically multiscale approaches. Multiscale calculations provide an accurate description of radiation effects in condensed matter through an understanding of energy transfer events, radiation track structure, physicochemical processes, diffusion-reaction competition kinetics, and the fate of radiolysis products over multiple length, space, and time scales. This level of understanding is achieved by a combination of track structure and independent reaction times kinetics simulations that utilize INL High Performance Computing resources, such as Lemhi and Sawtooth, coupled with a deterministic reaction kinetics model. This multiscale approach has been successfully used to interpret the radiation-induced chemistry of several solutes in complex aqueous solutions, including actinides.

Collaborative Capabilities

In addition to our in-house capabilities and expertise, the INL Center for Radiation Chemistry Research is actively involved in collaborative efforts to pioneer new irradiation capabilities.

In 2018, the center collaborated with the Brookhaven National Laboratory Laser Electron Accelerator Facility in the design and execution of a beamline setup for performing time-resolved electron pulse irradiation of actinide solutions. To date, this world-leading capability has been successfully used to measure chemical kinetics and elucidate fundamental mechanisms for the reactions of uranium, americium, curium, berkelium, and californium ions with radiolysis products arising from the irradiation of a wide range of solvents, including aqueous acidic solutions, organic liquids, and molten salts.

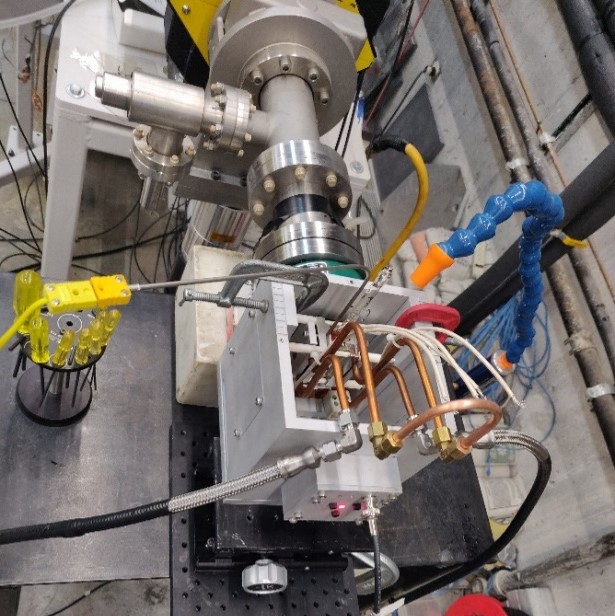

In 2023, a new steady-state irradiation capability was established, in collaboration with the Idaho State University Accelerator Center, to facilitate high dose rate electron beam irradiations of liquid samples at elevated temperature (≤ 700 °C). The bespoke sample cell holder can be installed at the end of the IAC 25 MeV S-band Varian 2500 linear accelerator, and has been successfully used to evaluate the radiation-induced chemistry of various sulfur chlorides and molten salt mixtures to date.

The new temperature-controlled, high dose rate electron beam setup at the Idaho State University Accelerator Center, successfully used to investigate the radiation chemistry of sulfur chloride compounds.