Developing the nuclear power systems of the future requires innovative thinking and new approaches to solving complex challenges. For the first time, a team of Idaho National Laboratory (INL) and University of Idaho researchers has successfully applied machine learning to characterizing the microstructure of metallic nuclear fuel, the fine details only visible under powerful magnification. The data collected through this technique will be used by engineers to predict fuel performance more accurately as they develop fuel for the next generation of nuclear power reactors.

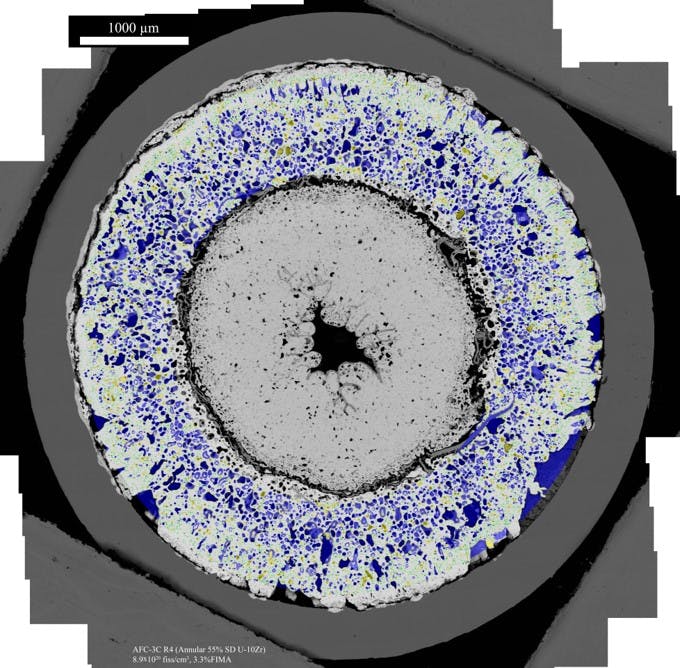

The research team, based out of INL’s Irradiated Materials Characterization Laboratory, developed machine learning approaches to extract and analyze a wide range of data points, such as the size and connectivity of fission gas bubbles, from irradiated uranium-zirconium fuel.

Gas bubbles are a natural byproduct of nuclear fission. As uranium atoms split apart, they produce heat along with smaller atoms including xenon and krypton. These and other byproducts are stored as bubbles within the fuel elements, resulting in microstructural changes that can limit the fuel’s ability to transfer heat to the reactor coolant, reducing efficiency.

The uranium-zirconium fuel under study by the INL team has been touted as the top option for several next-generation reactor designs and has advantages such as a simplified manufacturing process and increased fuel burnup.

Enhancing characterization with artificial intelligence

Machine learning involves feeding data into an algorithm that learns from the inputs and performs increasingly accurate analyses. The developed models can be extended to perform accurate predictions of material properties. Characterizing the microstructure of irradiated fuel, particularly the bubbles and fission products that may form during operation, is crucial for engineering nuclear fuel that is both highly efficient and effectively resists breaking down under potential accident conditions.

“The new approaches we developed will help us uncover the dynamic environment inside irradiated fuel in a nondestructive manner,” said Tiankai Yao, a post-irradiation examination specialist at INL. “It also allows us to significantly accelerate our post-irradiation examination work via an automated process and provides us with accurate information including fuel morphology, fission gas bubble density and lanthanide distribution.” Lanthanides are elements that form during reactor operations and inhibit fuel efficiency.

“We are building reliable and efficient machine learning approaches to help reveal and interpret valuable insights from high-quality nuclear fuel data,” said professor Min Xian, director of the University of Idaho’s Machine Intelligence and Data Analytics Lab. “We look forward to helping create a clean energy future using advanced AI techniques.”

Algorithms for quicker analysis

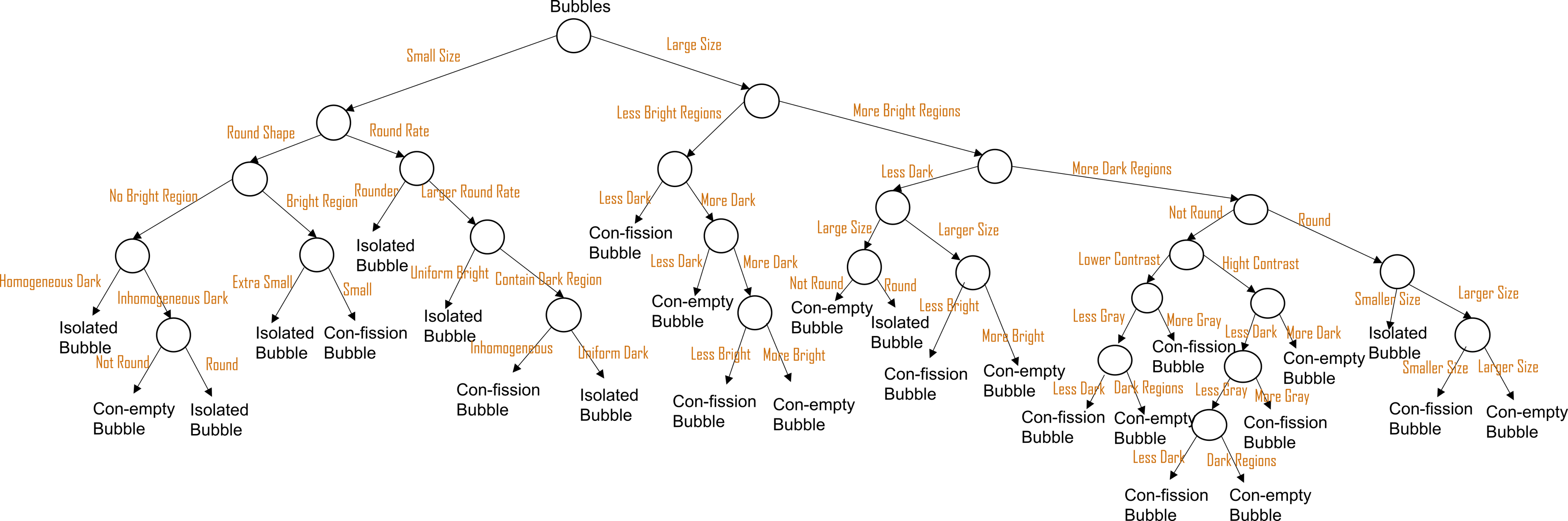

To develop the machine learning process, the researchers first created a comprehensive dataset with high-resolution images of fuel cross-sections and manual annotations of fission gas bubbles. They then implemented a machine learning algorithm, known as decision tree, to predict the category of each bubble using quantitative image features including bubble size, shape, and appearance. The algorithm is also designed to filter out “non-bubble” pixels in the images to enhance the speed of the process and account for varying levels of brightness to ensure accurate characterization.

“Our program uses a hierarchical methodology to sort images of fission gas bubbles with a high degree of accuracy and specificity,” said Fei Xu, an INL computation vision specialist.

The data generated will enable a better understanding of fuel performance dynamics, such as how the distribution of microstructures evolve as thermal conductivity decreases over time.

“We look forward to further refining this capability and potentially applying our algorithms to other areas of post-irradiation examination work,” said Luca Capriotti, an INL post-irradiation examination specialist.

The project has produced several notable insights into uranium-zirconium fuel performance, including identifying fuel thermal conductivity degradation due to extensive pore structure and an increase of connected pores in hotter regions of the fuel.

The findings have been published in the scientific journal “Materials Characterization,” available by subscription. The work was funded through the Department of Energy’s Office of Nuclear Energy and supported by the DOE Advanced Fuel Campaign.