Although his training is in biology, his real superpower is problem-solving.

Five years ago, Jeff Lacey’s kids started talking about buying a 3D printing pen. He thought it sounded like a good idea – but not a great one. Enter his superpower.

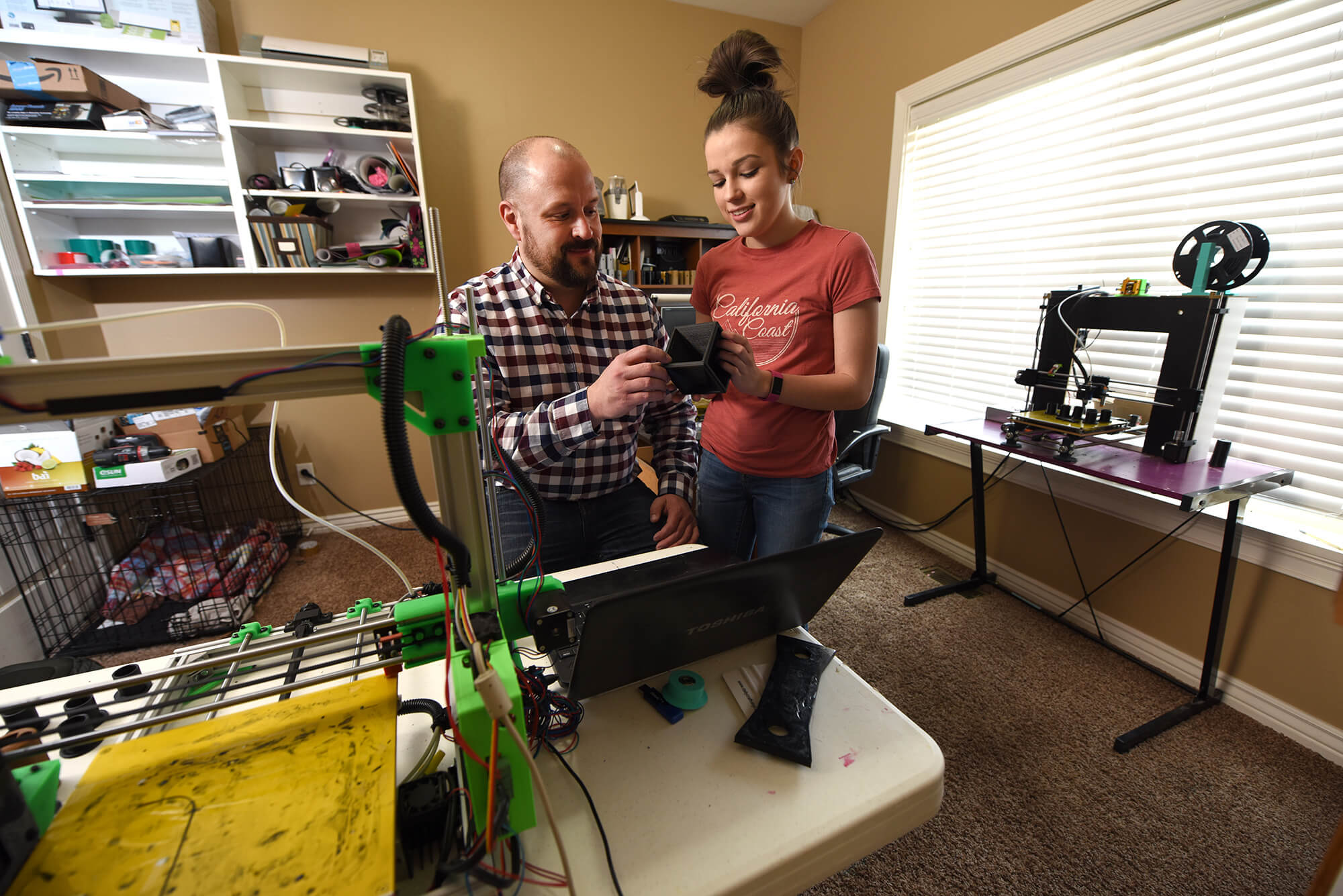

“I said, ‘Hey, what if you saved up some money and bought an actual 3D printer instead?’” His daughter, Hannah, 9 years old at the time, was all in. Together, the father-daughter duo raised $300 by making and selling homemade dog treats. (It was a lot of work, Lacey says.) Then he kicked in another $300 so they could buy their first, basic printer.

It has been a great investment – both in money and family relationships.

Together, they made lots of little gadgets and doodads. Every year, Lacey takes his printer to Hannah’s classroom and he lets it spend the day printing out a replica of Yoda from Star Wars, Frozen’s Elsa, or some other character. (Although creating things from a 3D printer is much faster than making a mold, it still takes a whole school day to print one Elsa.)

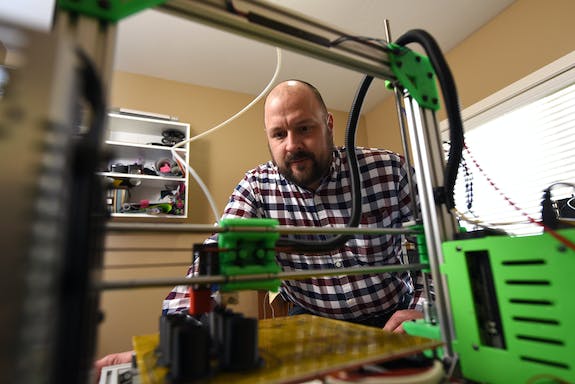

After mastering little toys, they used that first printer to build a better 3D printer that they named Neuromancer (from the cyberpunk novel Neuromancer). In turn, Lacey used Neuromancer to build an even better, fairly high-end printer that he named Wintermute (from the same book series). So from the beginning basic printer, he has created two sophisticated printers – and forged a stronger bond with his children.

By day, Lacey works at Idaho National Laboratory in the biomass program. His official title is staff scientist in the Biological and Chemical Processing Department. This biomass program studies how to get energy and fuels from excess biomass in the most cost-efficient way. It’s almost like spinning straw into gold – except it’s not a fairy tale. He, specifically, helps create a higher-quality starting material by removing foreign objects and lower-quality fractions that would hinder the process. Even some parts of the plant have minerals that are counterproductive to the conversion process. “There’s not a lot of wiggle room,” Lacey says. “In the biomass conversion process, everything is tied to a narrow price margin.”

Lacey’s undergraduate degree is in zoology; he has a master’s in environmental science and his doctorate is in plant science. So the stretch to 3D printing required additional skills. “I’m a biologist,” he says, “not an engineer. I didn’t know CAD modeling. I had some computer programming, but I’ve learned more.”

He is, however, a big do-it-yourselfer. His other hobbies include car and motorcycle restoration. The vehicle currently torn apart in his garage is a 1984 Porsche 944.

He also enjoys woodworking and fly fishing. “There is something very satisfying about catching a fish with a fly you tied yourself. It’s a reward for your mind.”

The same is true for his 3D printing hobby.

It’s a reward for his mind and he is always finding a new way to implement it. For example, he sometimes prints parts for whatever car he is restoring – especially if it’s something that isn’t available or quite expensive. “Sometimes, it’s just cheaper and faster to design and make a part than to hunt one down.”

Lacey credits his DIY instinct to his rural upbringing. “My dad always had us outside swinging a hammer,” he says. “We were always fixing or building something.”

His motto has become, “Why pay someone to do something if you can figure out how to do it yourself?” Although Lacey is the first to point out that the do-it-yourself approach doesn’t always work for him, when it does, “It feels good.”

Although he was always interested in 3D printing, he couldn’t justify the cost until Hannah got interested and he could see a value way beyond the initial $600 startup cost. (Beginner printers are even cheaper now – especially if you’re willing/able to start from a kit and put it together. A good quality, ready-to-go, off-the-shelf printer will set you back about $2,000 to $3,000.)

Some of his other 3D projects are designing/building connectors, bearing pockets, and other parts for mechanical duck decoys, and creating a prototype set of potatoes to demonstrate different sizes for a salesman to take to restaurants. His son, Conner, used the 3D printer to make a quadcopter for his senior project, which worked great until it crashed – a couple of times. On the upside, it gave him a chance to examine impact results.

In the future, Lacey would love for his research and hobby worlds to collide. Examples of where this might happen are using a 3D printer to create prototypes for pathogen detectors or creating a membrane separator for the purification of gases and liquids. The advantage of using a 3D printer for the prototypes is that you can create, reject and refine designs fairly quickly.

Although nobody knows their future for certain, it’s a good bet that Jeff Lacey’s will include something that he makes himself – possibly with a 3D printer.

Hobbies are fulfilling, and fulfilled people make more productive employees. Hobbies unearth hidden skills, alleviate stress, unite you with others, and improve quality of life — all things that will help you function better at work. See other stories about Idaho National Lab employees.