Keeping the nation’s lights on is no small job. The grid we take for granted involves large, expensive equipment, most notably power transformers. If one goes down, it can take more than a year to replace and at massive costs. In heavily populated, seismically active areas like California or the Pacific Northwest, time is not a luxury.

During an earthquake, the place where a large, high-voltage power transformer is most vulnerable is its bushings – hollow electrical insulators that safely guide current between a transformer’s internal windings and external power lines. They are most often made of porcelain due to its ability to isolate the conducting material, usually copper or aluminum, and keep high-voltage current from leaking or sparking and causing explosions.

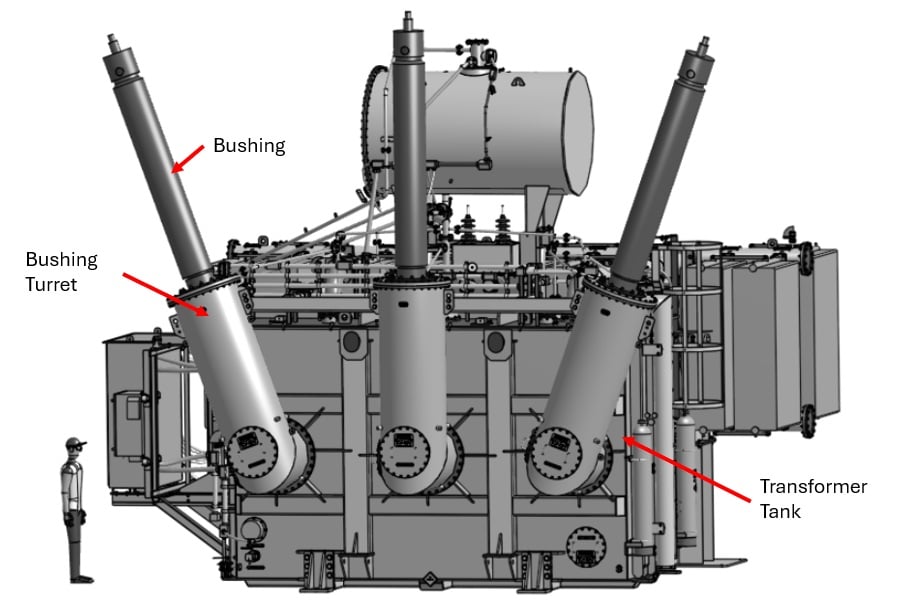

Bushings are bolted onto a transformer’s turrets, which extend up from the main tank (see Figure 1). These connections are what a team of researchers at the Idaho National Laboratory (INL) has focused on. The team’s goal is to develop a mechanically simple, adjustable isolator, known as a decoupler, that can be mounted at the base of a bushing and tuned to prevent resonant frequencies in the bushing and the turret from matching (which results in amplified mechanical stress on the porcelain bushing).

“Resonant frequencies are the lynchpin,” said Bjorn Vaagensmith, the principal investigator on the project and 2025 Presidential Early Career Award for Scientists and Engineers recipient.

Resonance explained

All objects have a resonant frequency, which occurs when input vibrations are maximally amplified in an object. When a sound wave shatters a wine glass or a mirror, that is resonant frequency at work. In the history of civil engineering, perhaps the best-known example is the collapse of the Tacoma Narrows Bridge in 1940. Wind speed and direction combined with the bridge’s design and materials to create a resonant frequency that caused its deck to oscillate wildly. This earned the newly built bridge the nickname “Galloping Gertie” – before it broke into pieces and dropped into Puget Sound after four months.

In an earthquake, seismic waves cause the up-and-down or back-and-forth oscillating ground motion that is transferred into large power transformers. Because of their flexibility and density, big power transformer tanks made of steel and filled with insulating oil can resonate dynamically with the equipment mounted on them. When a tank and its mounted bushings are on the same wavelength, there’s a danger the amplified shaking from the earthquake will stress the bushings to catastrophic failure.

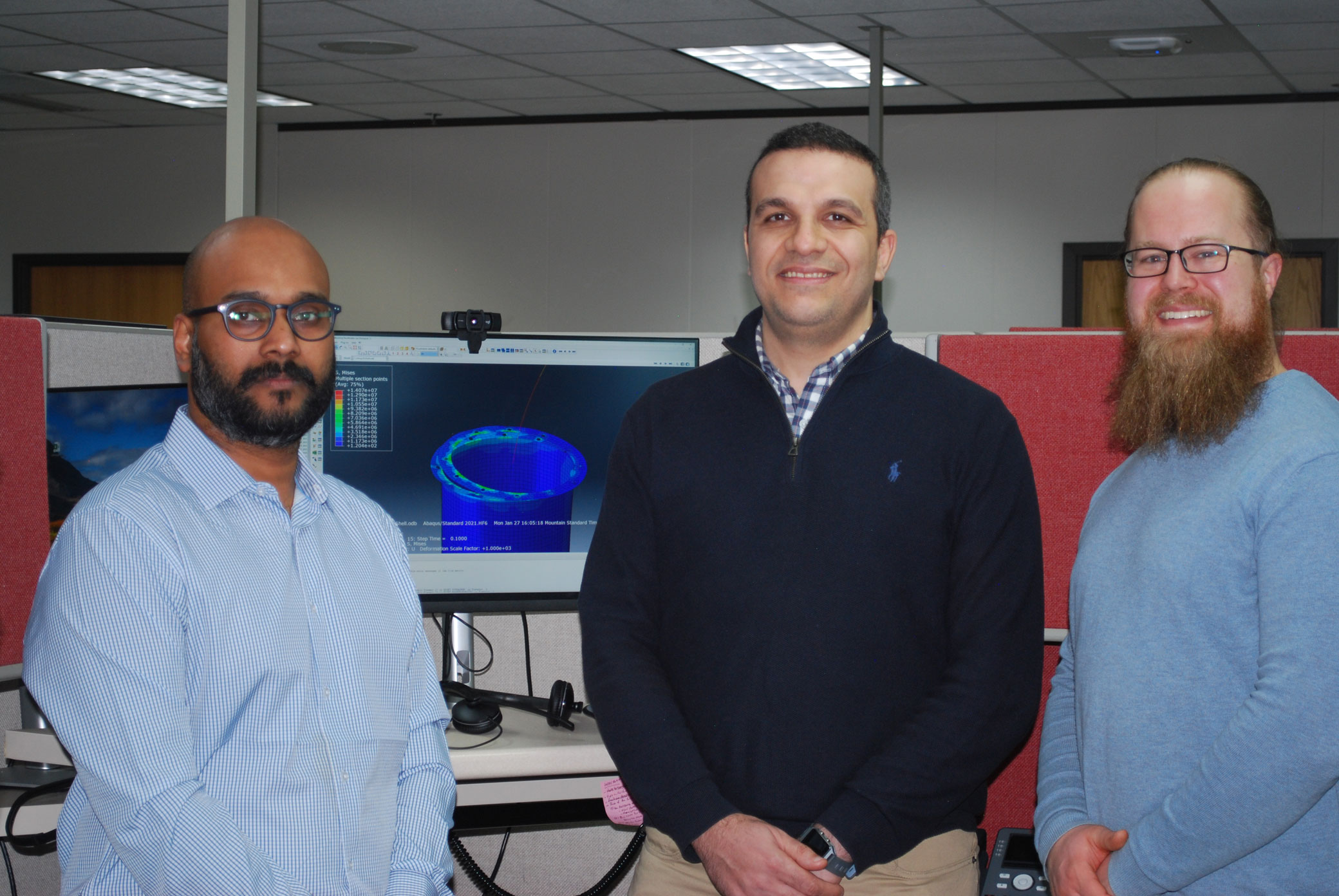

Vaagensmith and his colleagues – Chandu Bolisetti of INL and Jon Bender of WEGAI, a Boise-based engineering firm – are seeking to tackle this problem by inventing a decoupling device that shifts the resonance frequency of the bushing away from that of the transformer. The decoupler they are designing can be easily installed at the base of the bushing and retrofitted to older transformer models for a low cost. The team is pursuing a patent on the design.

Their project was initially funded through INL’s Laboratory Directed Research and Development program. It is now collaboratively supported by the U.S. Department of Energy’s Office of Electricity’s Transformer Resilience and Advanced Components (TRAC) program and the department’s Office of Cybersecurity, Energy Security and Emergency Response (CESER). The TRAC program exists to speed up grid modernization by addressing challenges in grid hardware technologies, including large power transformers. The CESER office aims to secure and strengthen U.S. energy infrastructure against threats and hazards.

At the culmination of their project, Vaagensmith and his colleagues hope to test their resonance frequency decoupler in a big way. They’ve managed to secure a 500,000-pound transformer, which they hope to take to the earthquake simulator at the University of California San Diego in 2026. The university’s shake table is the largest of its kind in the U.S. and rivaled only in size by another in Japan. This will be the first test of its size and could significantly impact safety requirements for transformers in seismic zones.

“This is a rare opportunity,” Bolisetti said. “To me, it’s miraculous.”

The main event

In collaboration with the University at Buffalo, the team has plenty of opportunities to get things wrong. That is the purpose of experimentation. “We can fail however we want to fail,” Vaagensmith said. “We can try out our solution and test to the limits. We want to be sure we know how to design the decoupler before we go to San Diego.”

Word in the industry is spreading, especially since the INL team gave a main stage presentation in October 2024 to the Institute of the Electric and Electronics Engineer’s Power and Energy Society Transformer Working Group Committee’s annual fall meeting, where industry standards for all things related to transformers are created. “People are excited about this,” Vaagensmith said. “We have an opportunity to resolve a longstanding debate about appropriate seismic transformer protection measures and come up with a solution for bushing manufacturers that doesn’t require them to retool. Utilities will be happy, and the grid will be more resilient. We already have people saying, ‘When are you selling tickets?’ Industry is very interested.”