An undergraduate, master’s and two doctoral nuclear engineering students came together this summer to collaborate on an in-core neutron sensor known as the Micro-pocket Fission Detector (MPFD). The four have spent their summer working on this innovative technology in the High Temperature Test Laboratory (HTTL) at Idaho National Laboratory. The MPFD provides researchers with enhanced, real-time data about reactor conditions during irradiation testing.

Sarah Stevenson is a senior in nuclear engineering at Kansas State University, while Kevin Tsai is pursuing his master’s degree in nuclear engineering at Idaho State University. Michael Reichenberger is studying for his Ph.D. in nuclear engineering at KSU and hopes to complete it in December. The mentor of the group, Troy Unruh, is pursuing his Ph.D. in nuclear engineering at ISU, and has been instrumental in facilitating continued MPFD development as an in-core instrumentation research scientist at the HTTL.

“I became familiar with the technology of the MPFD while obtaining my master’s degree at KSU, and I thought a collaboration between KSU and INL was the next natural step,” Unruh said. “We’ve been very fortunate to have it funded by the Nuclear Energy Enabling Technologies (NEET) program for the past five years.”

The MPFD, despite the advanced and unique capabilities it touts, is in appearance an unassuming pencil eraser-sized disk attached to wires. What distinguishes it from previous technologies is that as a multipurpose device, it can simultaneously measure temperature, thermal neutron flux and fast neutron flux within a single package. It is extremely small, robust, and boasts a fast response. Its most outstanding capability, however, is the ability to provide data about real-time conditions during irradiation testing.

“Because the core of a nuclear reactor is such a harsh environment, not much survives the heat and radiation. We’re working with very extreme conditions,” Reichenberger explained.

The current knowledge of the conditions inside the core is primarily based on data gathered before and after—but not during—irradiation tests. “The MPFD will play a key part in bridging this data gap by providing a real-time alternative,” Stevenson said.

“A very simple analogy I like to use is the concept of sticking a thermometer in something baking in an oven, except the MPFD is providing more information than just the temperature,” Unruh said.

Though the MPFD is still under development, its design has been proven and has undergone testing at the KSU TRIGA research nuclear reactor. It is headed to higher-power reactors for further testing. Current deployment plans include sending MPFDs to both the Advanced Test Reactor and the TREAT reactor on INL’s desert site.

“The work we’ve been doing here is extremely exciting, because we want the technology to be used, not just researched,” Unruh said. “INL has ongoing collaborations with other national and international laboratories, universities and companies interested in using this technology for themselves.”

Another noteworthy feature of the MPFD and other sensor technologies produced in the HTTL is that they are constructed and customized specifically for INL’s use.

These “aren’t gadgets that can be bought commercially, or produced by just anyone,” Reichenberger said.

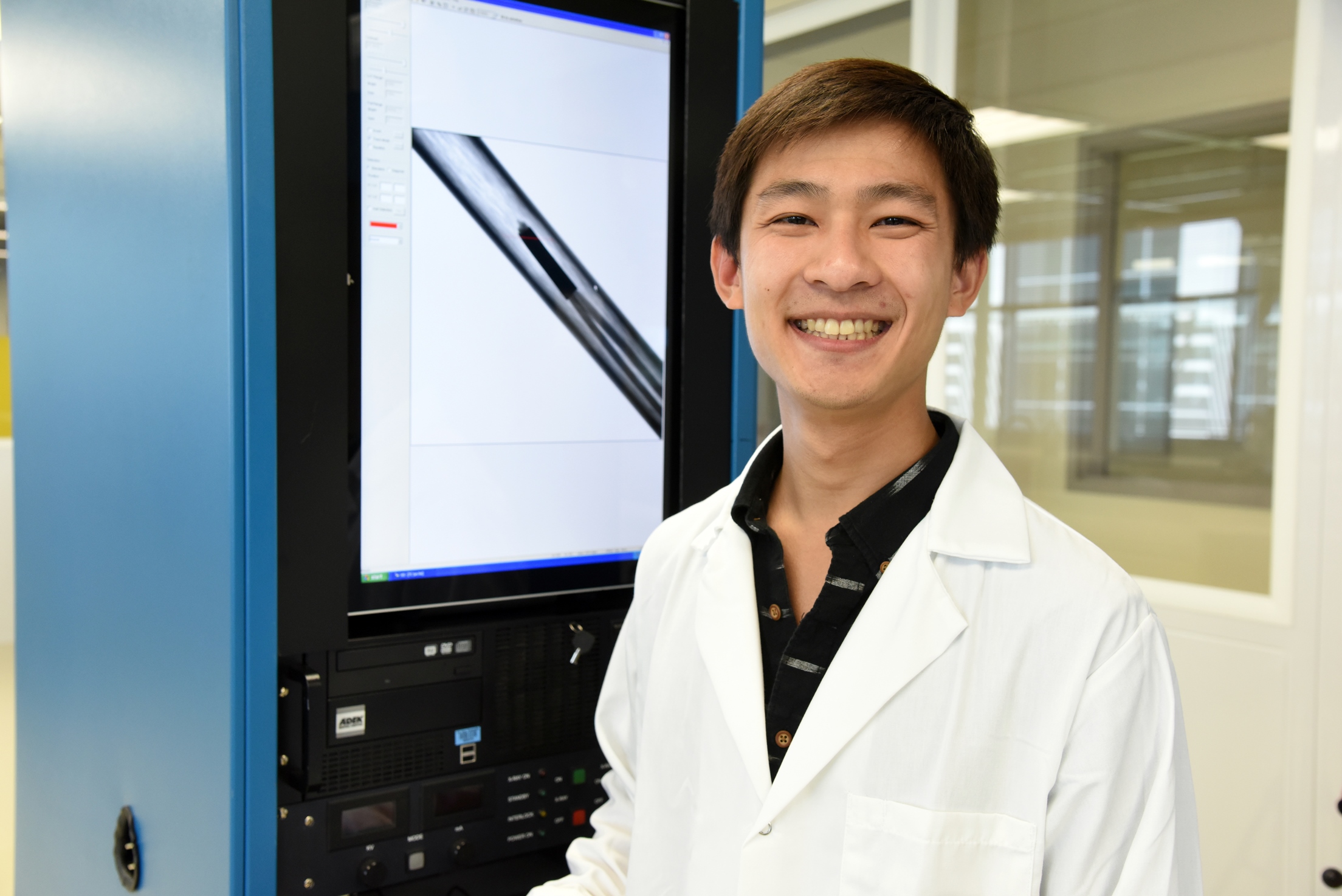

Recently, the U.S. Department of Energy (DOE) invested in a sophisticated nondestructive microfocus 3D Computed Tomography machine for the HTTL that has enabled the group to view, in detail, the precise construction of the MPFD.

“This equipment has made us that much more confident in our design, which is extremely important as the MPFD may be used in future nuclear fuel and material irradiations,” Unruh said.

The project has also proven to be an invaluable experience for the three interns beginning their professional careers. They have further cemented their collaborative efforts by participating in recreational activities outside of work, such as hiking at Craters of the Moon and visiting Lava Hot Springs.

“Working in the HTTL has given me valuable laboratory experience in fabrication of nuclear instruments,” Tsai said. “The connections I’ve made and experiences I’ve gained are instrumental in furthering my academic and professional career.”

At Kansas State University, Stevenson’s primary focus has been helping fabricate these devices. “My INL internship not only leveraged this experience,” she said, “but also elevated my perspective by introducing me to the various programs that want to use these detectors.”

This project has been distinctive because the interns are at varying stages of learning, and can use their individual knowledge to contribute to the world’s supply of nuclear energy, their mentor said. “We are able to take an idea from its conception to reality, and immerse ourselves as that process unfolds in front of us,” Unruh said.