CobaltREE

Decision Support Systems Tools

Model Description

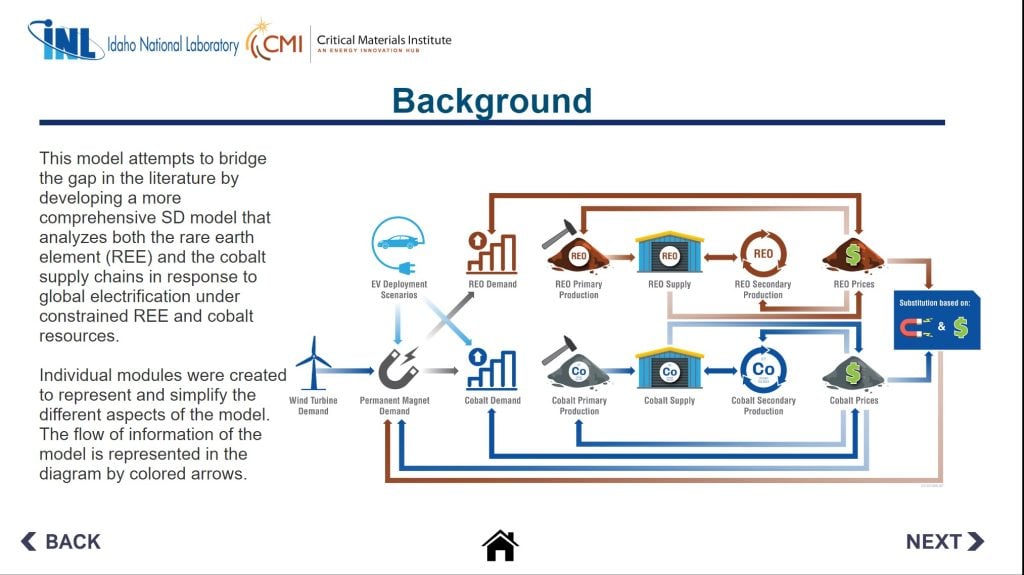

In this research, the authors attempt to bridge the gap in the literature by developing a comprehensive system dynamics (SD) model that analyzes both the rare earth element (REE) and the cobalt supply chains in response to a global deployment scenario of EVs. Approximately 80-90% of current EVs utilize rare earth permanent magnets in their traction motors. Sintered Nd-Fe-B magnets are used in EV motors due to their favorable characteristics, including high coercivity, thermal properties, and maximum energy product (BH)max range. One of the largest challenges of the Nd-Fe-B supply chain is that most magnet manufacturing takes place in China (92%) making the rest of the world (ROW) reliant on China’s output. To alleviate permanent magnet supply chain concerns, researchers with the Critical Materials Institute (CMI) have developed a lanthanum-neodymium (La-Nd) magnet as a substitute for sintered Nd-Fe-B magnets. In the La-Nd substitute, lanthanum and cobalt replace some of the neodymium and dysprosium used in the traditional sintered Nd-Fe-B magnet. The cobalt supply chain is already in tight supply and using more cobalt for the new magnet might further stress this supply chain.

To understand the impacts of substitution as well as key constraints to EV growth, this work was the first attempt to connect cobalt and rare earth supply chains.

The authors set out to answer three key research questions:

- What are the key constraints to EV deployment and does an alternative magnet or non-REE magnet motor technology alleviate the constraints?

- What individual improvements can be made to the cobalt or REE supply chain (depending on the key constraints) to improve EV sales?

- If EV deployment is still unfavorable after individual improvementracting Lithium from this source. This model links global demand and supply of lithium (Li) considering different electric vehicle (EV) demand scenarios.

Prerequisites

Methodology

License

Funding Source

This work is supported by the Critical Materials Institute, an Energy Innovation Hub funded by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Materials Manufacturing Technologies Office under Grant AL-12-350-001

This computer software was prepared by Battelle Energy Alliance, LLC, hereinafter the Contractor, under Contract No. AC07-05ID14517 with the United States (U. S.) Department of Energy (DOE). The Government is granted for itself and others acting on its behalf a nonexclusive, paid-up, irrevocable worldwide license in this data to reproduce, prepare derivative works, and perform publicly and display publicly, by or on behalf of the Government. There is a provision for the possible extension of the term of this license. Subsequent to that period or any extension granted, the Government is granted for itself and others acting on its behalf a nonexclusive, paid-up, irrevocable worldwide license in this data to reproduce, prepare derivative works, distribute copies to the public, perform publicly and display publicly, and to permit others to do so. The specific term of the license can be identified by inquiry made to Contractor or DOE. Neither the United States nor the United States Department of Energy, nor contractor makes any warranty, express or implied, or assumes any liability or responsibility for the use, accuracy, completeness, or usefulness or any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights.

Contact Information

Michael Severson