When University of Illinois researchers were developing a polymer that could revolutionize the manufacture of everything from airplanes to bicycles, they needed a computer model to fine-tune their invention.

But developing computer models can take time and money. Researchers who want to simulate complex science and engineering problems often resort to hiring programmers and building the model from scratch.

Instead, Philippe H. Geubelle, a professor of aerospace engineering at University of Illinois at Urbana-Champaign, found a better option: the Multiphysics Object Oriented Simulation Environment (MOOSE). His team published its results in the May online issue of Nature.

MOOSE is a framework developed at Idaho National Laboratory that allows researchers to build their own models by plugging in the right physics equations.

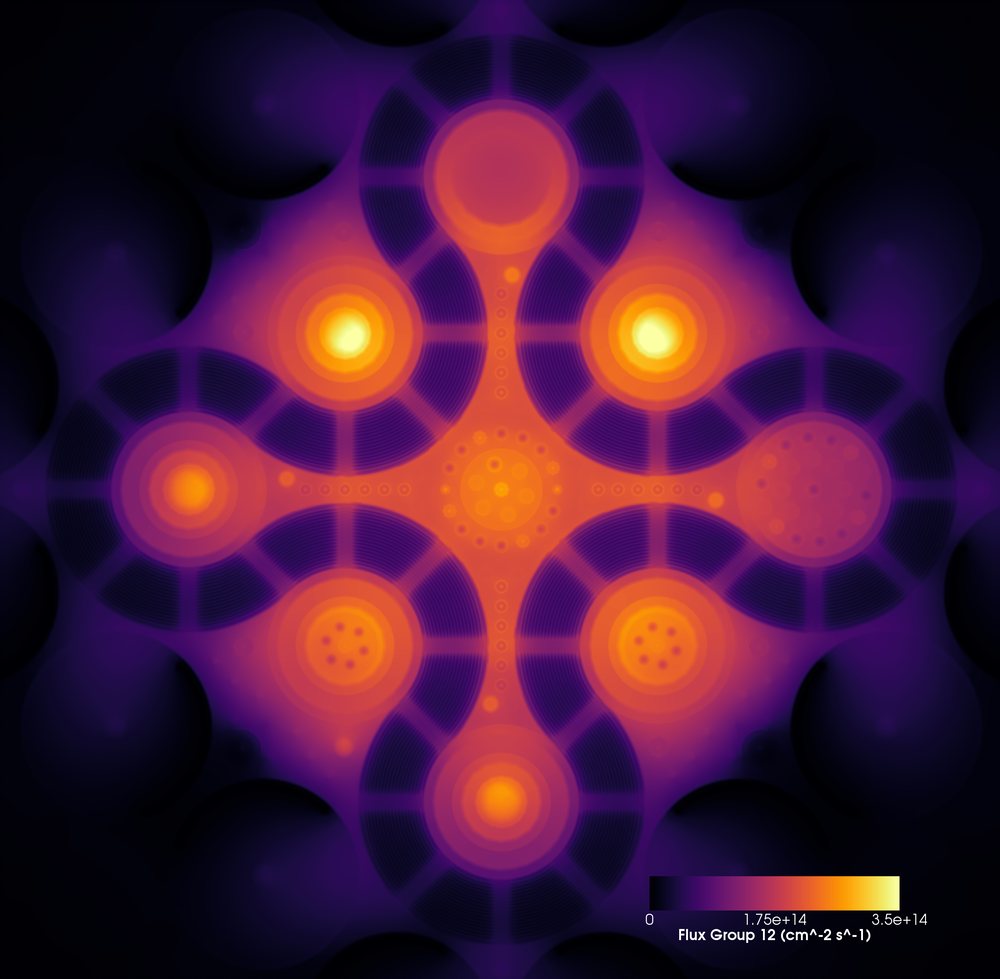

Though INL’s computer scientists originally designed MOOSE to model how nuclear fuel performs in a reactor, the open-source software is flexible enough to simulate all kinds of physics problems.

The MOOSE platform has spawned more than 40 applications (all named after animals native to Idaho) to model everything from nuclear fuel to the movement of fluids through shale to electromagnetic wave propagation.

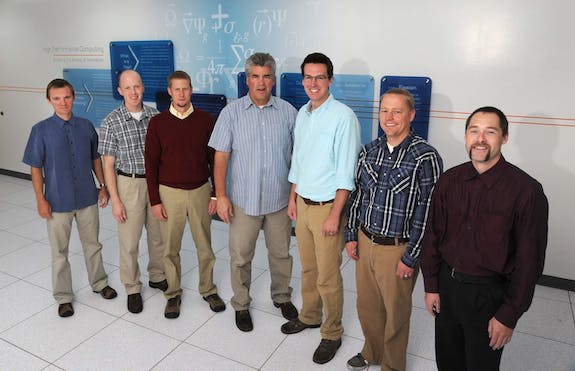

MOOSE is the brainchild of Richard Martineau, director of INL’s Nuclear Science and Technology Modeling and Simulation group, and Derek Gaston, a computational mathematician and MOOSE team lead.

“MOOSE takes care of the heavy lifting of computer science,” Martineau said. “It lets you just focus on physics. It’s a lot easier than coupling these disparate codes together that were created with different program languages, software designs and syntax languages.”

MOOSE not only allows researchers to develop simulations in a fraction of the time, but its state-of-the-art modeling and simulation techniques allow predictive simulations. MOOSE can also handle multiple simulations in parallel to describe the interactions of different phenomena.

For Geubelle and his modeling team, MOOSE was the ideal way to simulate their novel approach to curing their polymer during the manufacturing process.

Typically, when manufacturers build something out of polymers—say, an airplane fuselage—they must cure the part at high temperatures in an autoclave for several hours. This process is not only costly in terms of time and energy, but it also produces a lot of carbon dioxide.

The polymer developed by the University of Illinois team skips the autoclave step by curing itself. When a heating element touches the polymer in a gel or liquid form, the heat sets off a chemical reaction that causes the polymer to harden.

That chemical reaction, in turn, generates its own heat, which causes the reaction to propagate through the polymer. “We demonstrated that we can make parts of good quality, and we can do it in a fraction of the time and especially a fraction of the energy,” Geubelle said.

Geubelle and colleagues needed to know how to fine-tune the technique for different manufacturing scenarios. “The key contribution is the great control that we have with the chemical reaction,” he said. “You need a lot of heat to propagate the reaction, but you don’t want to create too much energy, otherwise the material will be degraded.”

To successfully simulate the self-curing polymer, Geubelle and his team needed a modeling platform that could handle the necessary reaction diffusion equations. The platform would need to describe not only the chemical reaction itself, but how the heat generated affects the entire system.

One of Geubelle’s students found the MOOSE software, which comes with physics modules that can handle heat transport, tensor mechanics and other types of equations needed to model the polymer reaction.

“They are basically using our tool to go in a completely different direction,” said Daniel Schwen, a staff scientist at INL who works on the computational methods development team.

This flexibility and support has helped MOOSE catch on with researchers around the world. Users include about 60 universities in the United States and dozens more in China, Australia, Japan, Russia and Europe.

The MOOSE user group, an online community to provide support for MOOSE users, is now approaching 1,000 members. There’s also a core group of programmers at INL who are interacting with that user community to constantly update the platform.

“The main thing that’s rewarding about this job is that it’s being used all over the world,” said Schwen, who has served as the lead developer for MOOSE applications such as MARMOT and MAGPIE.

“If somebody does encounter problems, that gives us ideas and drives the development,” Schwen said.