Since the start of the nuclear age, with very few exceptions, commercial nuclear power plants have served a single purpose: generating electricity.

Those plants worked well with older power generation and transmission infrastructure – large coal-fired, natural gas or hydroelectric plants, and a relatively simple electrical grid designed to deliver reliable power.

But now, researchers and industry must develop a new generation of nuclear power plants that will operate in an increasingly complex energy landscape.

Renewables such as wind and solar produce intermittent power, and conventional power plants operate best and are more profitable when they operate at full capacity. When plants are forced to operate at less than full capacity, power generation becomes less cost effective for customers and utilities.

Likewise, cybersecurity attacks, natural disasters and other threats present new challenges to maintaining reliable power into the future.

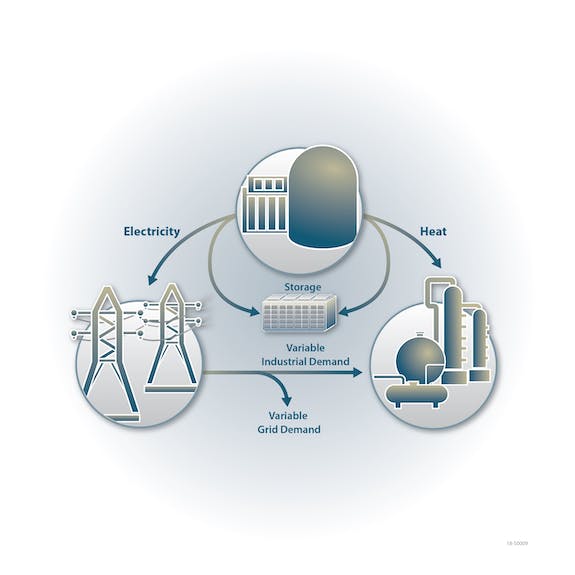

To meet these challenges, researchers and industry have developed technologies such as advanced microgrids, energy storage and integrated energy systems that divert excess capacity for industrial applications such as hydrogen production.

Next-generation nuclear plants will provide operators with the flexibility to adjust power outputs to match demand, to make crucial decisions about electricity generation and allocation of steam, to repel cybersecurity threats, and to maintain reliable power during natural and man-made disasters.

The Joint Use Modular Plant

To create this next generation of nuclear power plants, the U.S. Department of Energy is working with Utah Associated Municipal Power Systems (UAMPS) and NuScale Power to develop the Joint Use Modular Plant (JUMP).

The JUMP program will dedicate for nuclear energy research the first reactor module planned for the Carbon Free Power Project (CFPP), a nuclear power plant that UAMPS plans to build on the Idaho National Laboratory Site in the mid-2020s.

Since JUMP will be the first module fabricated and deployed at the CFPP, UAMPS and the DOE will be looking at ways to improve the efficiency and time required for subsequent module deployments for the CFPP, as well as subsequent advanced reactor deployments that are under consideration in the U.S.

The CFPP plant will consist of 12 independent NuScale small modular reactors (SMRs) in a shared pool. These SMRs – 60 megawatts electric each – will be constructed offsite and shipped to the plant located in the desert west of Idaho Falls.

Setting aside one of those 12 reactors for science presents researchers with a valuable opportunity, said Jess Gehin, chief scientist of the Nuclear Science & Technology directorate at INL.

“It would support research and development into the ability to utilize thermal energy storage, integration with other energy sources and potentially provide insights into other projects such as hydrogen production and desalinization,” Gehin said. “It would allow us to understand the impacts of interfacing these technologies with a full scale nuclear plant, which is very unique.”

Since the JUMP module has not yet been constructed, researchers and engineers can consider changes to the system to support research objectives, such as the means for integrating equipment with the steam-producing side of the reactor. This simplifies the development since the changes can be incorporated directly into the fabrication and construction of the plant, rather than retrofitting changes to an existing plant.

Such equipment could include infrastructure designed to divert steam from the turbine for integrated energy systems that would use excess capacity of a given power plant to produce commodities other than electricity – without interrupting the reactor’s ability to generate electricity.

“When we talk about integrated energy systems, there are several approaches we can take,” said JUMP Program Director Shannon Bragg-Sitton, lead for the DOE Office of Nuclear Energy integrated energy systems program. “We can divert a varying fraction of the steam from the turbine to drive industrial process such as the production of hydrogen, ammonia or other chemicals. Through the use of techniques to upgrade the temperature of that steam we can couple water-cooled reactor technologies, such as NuScale, to higher temperature processes.”

Connecting JUMP with Existing Capabilities at INL

The JUMP reactor could connect with existing capabilities at INL such as the Systems Integration Laboratory (SIL) – a suite of interconnected systems that allows researchers to simulate microgrids, advanced vehicles, hybrid energy systems, renewable energy, energy storage and more.

The Systems Integration Lab includes the Digital Real-Time Simulator (DRTS), a system that simultaneously models power grid infrastructure and thermal and mechanical systems to test any number of hypothetical scenarios from natural disasters to cyber attacks to the simultaneous charging of millions of electric vehicles.

The JUMP module could also connect with the microgrid test bed at INL, which includes solar panels, energy storage devices, load banks, smart inverters and a power distribution system.

Through these connections with SIL and the microgrid test bed, researchers would be able to test any number of scenarios – from an increase in energy production from a real-world renewable site to a simulated cyber attack or a hurricane – and monitor how the JUMP module would respond.

“It gives us the potential to maneuver energy between electricity production and integrated processes based on signals from the nearby Horse Butte Wind Farm (also owned by UAMPS), for example,” Bragg-Sitton said.

Additional Instrumentation

The JUMP program would include additional instrumentation to monitor the inside of these novel small modular reactors. This will give researchers, industry and regulatory agencies high-quality data to improve the reactor efficiency and fuel performance.

The addition of instrumentation and the use of the reactor for testing fuels, sensors and materials will be planned so that it does not change the licensing process of the UAMPS NuScale reactor, which is currently underway.

“NuScale is proud to provide a cost-effective, one-of-a-kind opportunity for the national laboratory to conduct RD&D at the country’s first commercial SMR,” said John Hopkins, NuScale Power chairman and chief executive officer. “NuScale’s involvement in the JUMP Program is yet another way NuScale is revolutionizing the face of nuclear energy and pioneering the clean, safe and resilient energy of the future.”

NuScale’s SMR technology uses a safer, smaller and scalable version of pressurized water reactor technology, and relies on natural convection instead of pumps to circulate the water that is used as a coolant within the reactor vessel. The extra instrumentation “provides us with so much additional data to characterize the flows associated with this novel design,” Bragg-Sitton said.

In the long run, that data could help reduce the capital and operating costs of new nuclear reactors in the future. “We overdesign when we don’t have high fidelity data,” Bragg-Sitton said. “The more conservatisms that we build into the system design, the more it costs. If we can improve the data on flow regimes and temperatures within the reactor, we can better optimize the design and reduce costs.”

The additional sensors will also provide for validation of advanced computer codes being developed by DOE’s Nuclear Energy Advanced Modeling and Simulation (NEAMS) program, including next-generation reactor systems analysis capabilities.

In addition to extra instrumentation, Bragg-Sitton hopes to incorporate a vessel where test samples – accident-tolerant fuels, new sensor technologies and new reactor materials, for example – could be introduced into the JUMP reactor vessel to test how they withstand the operating conditions of a commercial reactor.

Human Factors

The JUMP reactor also presents an opportunity to learn about how human operators are impacted by these new technologies.

A control room mockup could be used to monitor physiological signals of operators, tracking eye movements and cardiopulmonary signals, for instance, to help researchers understand how operating a next-generation nuclear plant impacts operator behavior and stress levels.

A Collaborative Vision

All said, the JUMP module has benefitted from the input of dozens of government and industry researchers and engineers.

“It’s not just a DOE lab-led push, but also supports research and development needs from NuScale and other industry partners who will benefit in the future,” Bragg-Sitton said.

“We surveyed various relevant programs across the national laboratory system to develop some of these preliminary concepts for research,” she continued. “NuScale is also looking at opportunities for JUMP to demonstrate plant resiliency to external events.”

Last year, NuScale unveiled a collection of resiliency studies suggesting that NuScale’s SMR design is more resilient than any currently operating reactor. The findings indicated the design’s resilience to a variety of events and its ability to provide first responder power.

“UAMPS welcomes this opportunity to have the Department of Energy and Idaho National Laboratory use a module from the Carbon Free Power Project for research and development,” said Doug Hunter, UAMPS CEO and general manager. “Their interest demonstrates support for the CFPP and the potential of next-generation nuclear technology. I’m confident that scientists will learn a great deal, especially the opportunity to integrate SMRs with renewable energy and energy storage. This research can help the United States maintain leadership in the critical field of advanced nuclear technology.”

For more information, visit:

- DOE Office of Nuclear Energy announces agreement supporting power generated from small modular reactors

- What is the Carbon Free Power Project?

- INL Hybrid Energy Systems video