Advanced nuclear technologies could play an important role for nations seeking carbon-free energy solutions to reduce the impacts of climate change.

Companies around the world are developing advanced reactor designs to meet a range of needs, from microreactors for remote applications to large reactors that could power huge urban areas while also providing heat for industrial applications such as hydrogen production.

While these advanced reactors are a diverse bunch, they all benefit from both passive and inherent safety design features that use advanced materials to increase safety, reliability and performance.

One type of inherently safe technology, TRi-structural ISOtropic particle fuel (TRISO), consists of a kernel of uranium-based fuel surrounded by three layers of carbon- and ceramic-based materials chemically and structurally resistant to degradation in a reactor environment.

The resulting fuel particle is roughly the size of a poppy seed and can withstand temperatures of more than 3,000 degrees Fahrenheit, well beyond the threshold of current nuclear fuels, without melting or releasing significant quantities of fission products.

As more reactor companies look to TRISO particles to power their designs, understanding how these tiny fuel particles perform on the microscopic scale is vital.

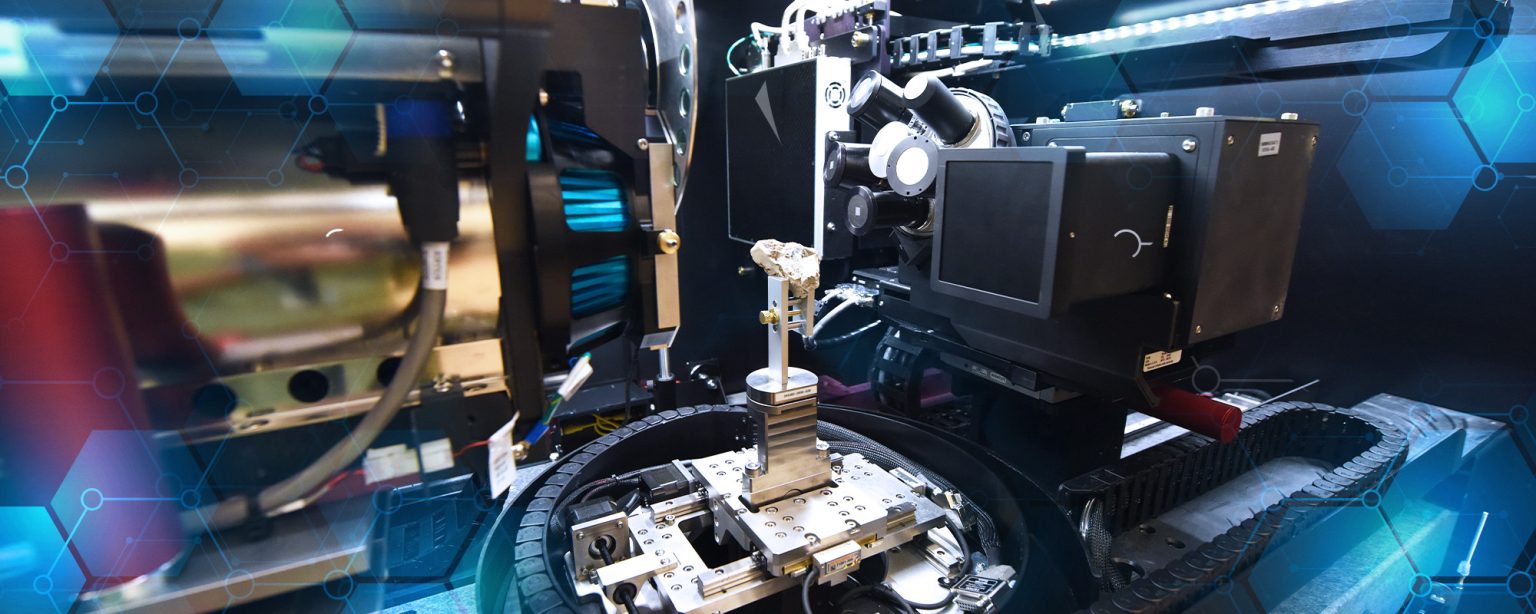

For the first time, researchers at Idaho National Laboratory have adapted a commercially available X-ray microscope to examine the internal structure of the uranium kernels inside irradiated TRISO particles. The particles were irradiated for 560 days in INL’s Advanced Test Reactor.

This technological leap in nuclear fuel imaging can help researchers identify mechanisms of fuel degradation and collect data to inform computer models of nuclear fuels. That data helps companies develop and qualify fuels for their reactor designs.

A slice of the picture

TRISO fuel particles are usually investigated by physically cutting the particle and using optical microscopy or scanning electron microscopy. While these methods provide researchers with useful information, they only show a slice of the picture, and at least part of the sample is destroyed in the process.

“We usually grind through a sample, polish it up and examine the cross-section,” said John Stempien, an INL scientist who specializes in post-irradiation examination of TRISO fuels. “This technique works well, but to prepare a cross-section, part of the sample has to be removed, and some information is lost in that process.”

The new method uses X-ray computed tomography, a technique that takes multiple 2D X-ray images of a specimen. A computer then assembles those 2D images into a 3D image for examination.

In the past, researchers used X-rays to successfully examine the carbon and ceramic layers of TRISO fuel coatings. But high-quality X-ray images of the uranium kernel interior have been elusive.

A shadow image full of artifacts

“Uranium is hard to get X-rays through,” said Nikolaus Cordes, an INL instrument scientist. “Low energy X-rays of the kernel are not especially accurate. The kernel acts as a beam stop. You’re getting a shadow image that’s full of artifacts.”

Those artifacts — details in the image that aren’t really there but are a byproduct of the low energy X-rays — can mislead investigators or obscure important details of the fuel particle under examination.

To get quality X-ray images of TRISO particles, Cordes and his colleagues used high energy X-rays and a special X-ray filter that blocks low-energy X-rays. “By throwing away those low-energy photons, we prevent a lot of artifacts from being created,” Cordes said.

The new technique allows researchers to image the entire TRISO particle nondestructively. They can then use destructive techniques such as optical microscopy or scanning electron microscopy to zoom in on interesting details.

“Analyzing random pieces of a particle is like trying to find a needle in a haystack,” said William C. Chuirazzi, an INL researcher who specializes in imaging and analyzing nuclear materials. “Now, if we see areas of interest in the 3D X-ray image, we can target this with more destructive techniques.”

The technique is also useful for examining fuel elements, where thousands of TRISO particles are embedded in a matrix material for insertion into a reactor.

Conditions inside a reactor

One specific question the new X-ray technique can help answer is how the conditions inside a reactor — i.e., neutron radiation and heat — damage a TRISO particle’s containment layers and uranium kernel.

“We’re really interested in fuel kernel swelling and how it affects the low-density carbon buffer layer around the fuel kernel,” Cordes said.

Just as important, the new imaging method can answer questions about the silicon carbide layer, and whether that layer remains intact without having to destroy the sample.

Further, the uranium kernel can develop pores that allow these fission products to move in unexpected ways that are revealed by the imaging technique.

More and better data for computer models

The new X-ray imaging technique will open the door for additional investigations of TRISO particles that will provide more and better data. That information can then be used to develop high-fidelity computer models of how TRISO particles perform in a reactor.

“If you have a reliable model, you can do scoping calculations to learn about how fuel behaves in a new reactor design that hasn’t been tested before having to do some of the more expensive and time-consuming experiments,” Stempien said.

In the end, these models and data will help reactor developers qualify their fuels and navigate the regulatory process.

“Our hope is to continue this work and get a real-world representation of a sample that can be used for model testing and validation,” Cordes said. “It would be a significant step for INL, as well as the broader scientific community, as we work to bring the next generation of nuclear fuels closer to reality.”