Molten Salt

Research

Molten salts are a diverse group of fluids that can be used for a variety of applications, including nuclear fuels and coolants, purification and separation of chemical species, and energy storage.

INL is studying and solving complex issues associated with advanced energy production and used fuel management for effectively and safely deploying future energy solutions.

Molten Chloride Reactor Experiment

In a collaboration between Southern Company Services, TerraPower, and Idaho National Laboratory (INL) (as well as other partners), the Molten Chloride Reactor Experiment (MCRE) is a six-month sub-scale test that will demonstrate the first operational fast spectrum molten salt critical system in the world.

INL will synthesize and handle the fuel salt, load and operate the reactor, and perform all post-operation deactivation and disassembly work.

This public-private partnership under the Department of Energy Office of Nuclear Energy’s Advanced Reactor Demonstration Program, will provide the data necessary to take the next step toward licensing a commercial Molten Chloride Fast Reactor.

MCRE is expected to be built and operated at the National Reactor Innovation Center’s Laboratory for Operation and Testing in the United States (LOTUS) testbed.

Studying Molten Salt Chemistry and Electrochemical Properties

Molten salts are widely used in a variety of applications, such as purification and isolation of target metals, energy storage, and as nuclear fuels and coolants.

To better understand how molten salts change in high-temperature environments, like a nuclear reactor, INL researchers are developing and demonstrating nonintrusive spectroscopic methods to measure salt compositions and remote sensors for real-time monitoring of the salt’s composition.

Researchers are also developing molten salt flow loops to investigate how temperature, salt chemistry and containment materials impact corrosion, thermal hydraulics and heat transfer.

Researching Salt-Based Fuel Cycles

Molten salts can also be used to recycle previously used fuel, a technique known as pyroprocessing. This reprocessing recovers valuable elements, such as uranium and plutonium, that can be reused in nuclear reactors. Researchers support ongoing recycling processes for recovering uranium from used Experimental Breeder Reactor-II (EBR-II) fuel as well as advanced processes with improved economics and safeguards-by-design features.

Investigations include fundamental properties of molten salts, especially for uncommon and harder to handle components, such as transuranic elements and irradiated fuels. Researchers and engineers are also developing scalable technologies for fuel salt synthesis, from both fresh and recycled materials.

Researchers are also investigating waste form solutions for salt-based radioactive wastes, including salts from both pyroprocessing and molten salt reactors.

Research Laboratories and Demonstration Facilities

INL has several laboratories dedicated to molten salt research.

INL has several laboratories dedicated to molten salt research.

The pyrochemistry labs in INL’s Energy Innovation Laboratory are used to characterize surrogate fuel salts (i.e., nonradioactive salts that mimic the behavior of those used in a reactor), perform corrosion studies, analytical and experimental electrochemistry, spectroscopy, and nuclear waste form development.

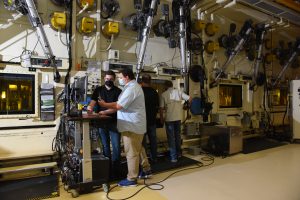

The Engineering Development Laboratory contains multiple inert atmosphere glove boxes and high-temperature furnaces used for molten salt research and process development. The Water Chemistry Laboratory contains a single-sided inert atmosphere glove box, fume hood and space for benchtop experiments and analysis. The Turbine Deck is a large room capable of equipment testing. It houses a robotic arm and 3D printer for rapidly prototyping materials and mechanical hardware.

The Irradiated Materials Characterization Laboratory is a multiuse facility focused on microstructural, microchemical and micromechanical analyses and characterizing irradiated nuclear fuels and materials.

The Analytical Laboratory provides chemical, radiochemical, physical and analytical data for radioactive samples.

The Fuels and Applied Science Building is a radiological facility that houses small hot cells, glove boxes, and equipment related to nuclear fuel fabrication, used fuel treatment options and nuclear waste management. It houses a 46-foot-long glove box dedicated to pyrochemical system development. This glove box includes a series of molten salt furnaces for experimentation and fuel salt synthesis.

The Fuel Conditioning Facility supports treatment of DOE-owned sodium-bonded metallic fuel. It also houses a glove box with a developmental electrorefiner used for process testing and demonstrations at the 1–10 kg scale.

The Hot Fuel Examination Facility (HFEF) is INL’s flagship facility for conducting post-irradiation examinations of fuels and materials. Related to molten salt research, HFEF contains the scalable pyrochemical recycling (SPYRE) test bed, which is capable of testing pyrochemical recycling of used fuels at the 1–10kg scale. HFEF also houses a 10–100-gram scale furnace used for small-scale tests with used fuel, and several controlled atmosphere furnace systems. These systems are heavily used for electrochemical, pyrochemical, voloxidation, and waste form process development and testing.

The Molten Salt Thermophysical Examination Capability (MSTEC) is a forthcoming state-of-the-art shielded argon glove box for irradiated and nonirradiated actinide materials. Funded by the National Reactor Innovation Center, MSTEC will offer a suite of thermophysical property characterization equipment, multifunctional furnaces and versatile workspaces for lab-scale experiments.

Energy Frontier Research Center for Molten Salts in Extreme Environments

Led by Brookhaven National Laboratory, INL is a partner on the Energy Frontier Research Center dedicated to providing fundamental understanding of molten salts.

Molten Salt News

For decades, light-water nuclear power plants have provided safe, reliable carbon-free energy in the United States and around the world....Read More

Salt isn’t just for popcorn anymore. In fact, molten salt has caught the eye of the nuclear industry as an...Read More

Idaho National Laboratory researchers have won funding from one of the nation’s largest sponsors of research in the natural sciences.

Idaho National Laboratory’s Center for Radiation Chemistry Research has developed a capability that supports the nuclear energy industry by researching...Read More

A new collaboration between INL and the University of Utah hopes to make fuel recycling a reality for advanced reactors.

Not finding what you are looking for? Please send your question to [email protected].