Over the next few decades, dozens of coal power plants around the country will reach the end of their operational lives, and will need to be replaced with new, clean energy sources.

The city of Kemmerer, Wyoming, home to a coal-fired power plant that is slated for retirement in 2025, has found itself in the spotlight as the center of a new kind of clean energy project.

Kemmerer is the proposed site of a new sodium-cooled fast reactor plant designed by nuclear innovation company TerraPower. The Natrium reactor could help the community remain an energy town and continue providing jobs to support the local economy, and it could be operating around the end of the decade.

But there’s a long path to traverse between here and there for TerraPower to commercialize its technology, and many private innovators in the nuclear space lack the dedicated facilities needed to take a reactor from the drawing board to the real world. That’s where the National Reactor Innovation Center (NRIC) supports companies like TerraPower, by facilitating partnerships between the private and public sector to enable the technology demonstrations and eventual deployment of advanced reactor projects like Natrium. A significant portion of that work is taking place at Idaho National Laboratory (INL), utilizing its unique expertise and nuclear research and development facilities.

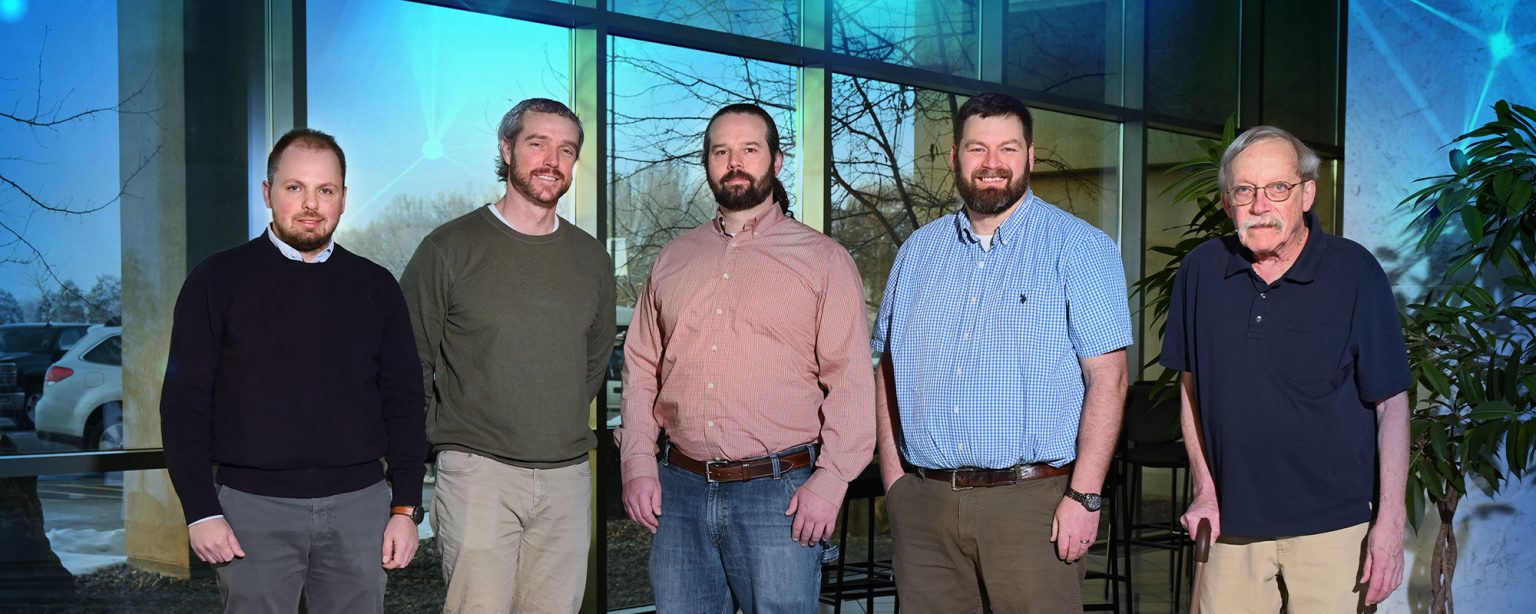

The NRIC team includes a dedicated group of professionals from across INL who specialize in helping the private industry navigate the steps from concept through testing, licensing and construction. They lead research and development activities and consult with TerraPower to execute NRIC’s mission of accelerating advanced reactor demonstration and deployment.

- Doug Porter, an INL Fellow, is the program’s overall technical lead. Porter started at the lab in 1977, working on fuel fabrication issues and doing in-core experiments for Experimental Breeder Reactor-II. He also led the fuel development component for the Integral Fast Reactor Program. Porter oversees the technical direction and outputs of the program. He works with TerraPower and NRIC staff members to ensure that planned and performed activities meet the technical requirements specified in agreements. Porter also offers directional consultation to TerraPower on their initial fuel design.

- Also assisting TerraPower with developing the fuel is Randall Fielding, who leads fabrication development efforts for the commercial Natrium reactor fuel. Fielding started at the lab in 2001 and has worked in a number of fuel fabrication roles since then, focusing mainly on metallic fuels, but he has worked with most other fuel forms. In his current role Fielding directs a team of engineers, scientists and technicians providing important development data to TerraPower so the fuel can be produced for testing.

- Colby Jensen is the fuel performance testing lead. He has been designing, analyzing and leading irradiation experiments in INL’s test reactors for more than eight years and is currently the lab’s technical lead for testing potential accident scenarios known as transients. He provides technical direction for all of the testing that ensures TerraPower’s fuel performs as designed in regular operation as well as during hypothetical accident scenarios. This is a critical part of making TerraPower’s reactor a reality and takes advantage of facilities like INL’s Advanced Test Reactor and Transient Reactor Test Facility.

- Luca Capriotti is the technical lead for post-irradiation examination (PIE), which confirms how the fuel behaves during testing. Capriotti started at INL in 2016, and he has been working on PIE of metallic fuel for sodium fast reactors for the last 10 years. He coordinates a team of scientists executing PIE activities across INL to provide critical data supporting Natrium’s licensing efforts. He works with TerraPower to define the technical requirements of examinations, such as scanning electron microscopy, chemical and isotopic analyses, and fission gas release measurements.

- In addition to fuel testing and analysis, INL provides TerraPower with digital engineering expertise, which helps reduce costs and streamline engineering processes through tools including advanced data collection and analysis. Leading this aspect of NRIC’s work is Ross Hays, who supports a diverse team of individuals from TerraPower, Bechtel, GE and INL in implementing digital engineering principles and software solutions for the Natrium project. He has been at INL for the past eight years, supporting advanced fuel cycle scenario analyses, biomass feedstock logistics calculations, and more recently digital engineering tool development for the Versatile Test Reactor.

NRIC has the resources of the national laboratory complex at its disposal to help advanced reactor developers like TerraPower progress toward commercialization. With NRIC’s support, the nation can act more quickly to address the need for clean and affordable energy. For more information, visit nric.inl.gov.