INL News Release

FOR IMMEDIATE RELEASE

April 21, 2022

NEWS MEDIA CONTACTS:

Michelle Goff, (208) 932-6581, [email protected]

Sarah Neumann, (208) 520-1651, [email protected]

The development of new, more efficient electrochemical cells could provide a good option for carbon-free hydrogen and chemical production along with large-scale electricity generation and storage.

But first, scientists must overcome several challenges, including how to make the cells more efficient and cost-effective.

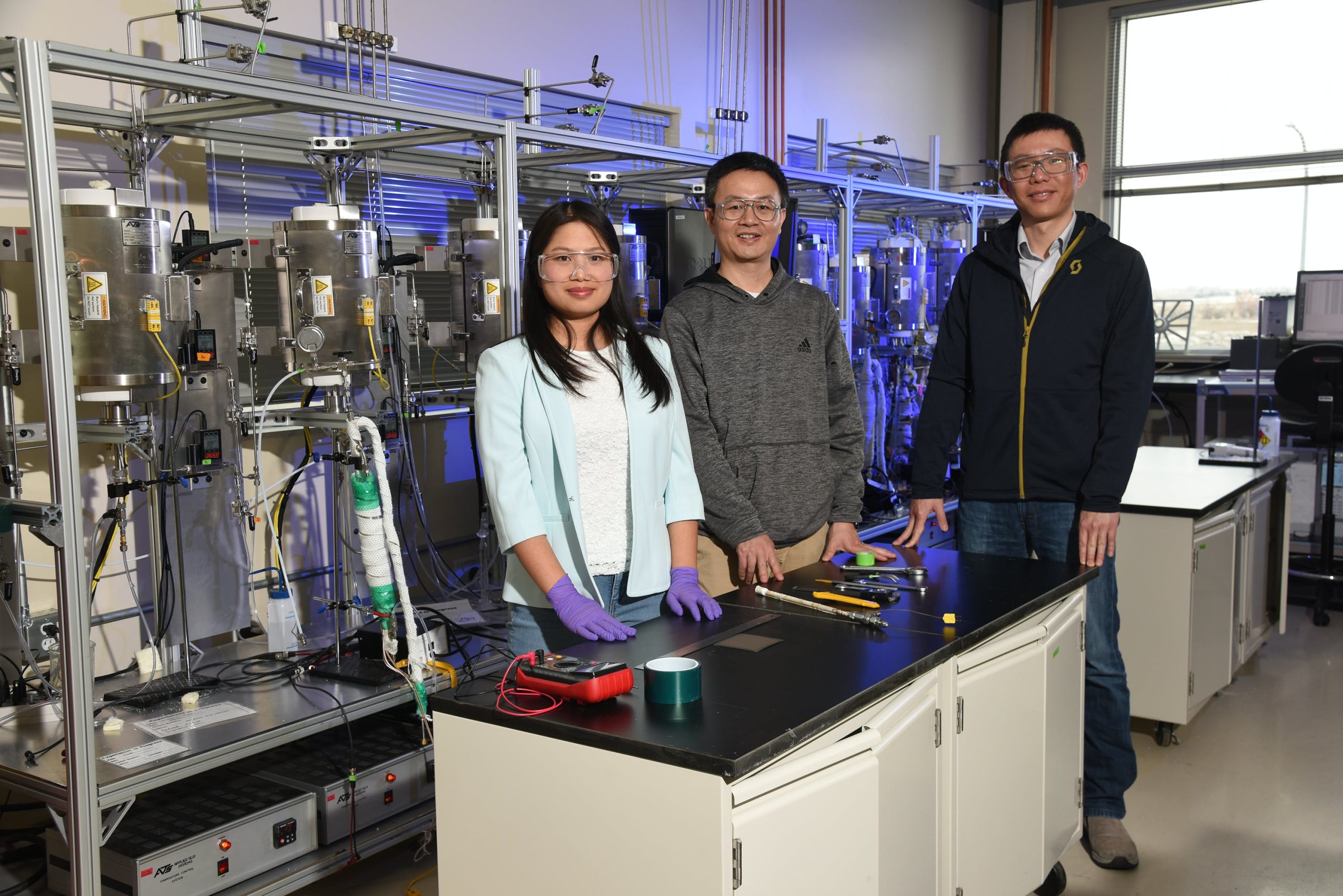

Recently, a research team led by Idaho National Laboratory used a simple process to bind materials more tightly within protonic ceramic electrochemical cells, also known as PCECs, solving a mystery that had limited the technology’s performance. The results were published in the latest issue of the scientific journal Nature. This is the first INL-led research paper published in that journal in almost 30 years.

The team included researchers from Massachusetts Institute of Technology, New Mexico State University, and the University of Nebraska-Lincoln.

Just as rechargeable batteries use chemistry to store electricity for later use, PCECs can convert excess electricity and water into hydrogen. PCECs can also operate in reverse, converting hydrogen into electricity. The technology uses crystalline materials called perovskites, which are inexpensive and capable of operating at a wide range of temperatures.

Researchers in the U.S. are developing the electrochemical cells primarily for hydrogen generation, but also several other applications. The hydrogen produced by these cells can also be used as fuel for heat, vehicles, chemical production or other applications.

In theory, PCECs should operate more efficiently at a wider range of temperatures than similar types of electrochemical cells. But until now, researchers could not achieve the technology’s theoretical potential.

“PCECs should perform well due to their high conductivity and small activation energy associated,” said Dong Ding, a distinguished staff engineer/scientist at INL. “Yet, we found that their present performance is lower than what we expected, and our team at INL has been devoted to understanding why since 2017.”

The team set out to solve the mystery by measuring how well protons (positively charged hydrogen atoms) flowed across the electrode/electrolyte interface. Sure enough, the interface was the problem. Specifically, Wei Wu, a materials engineering researcher at INL, suspected that the electrode and the electrolyte weren’t bound tightly enough.

Ding and his colleagues used a simple acid treatment to bond the electrode to the electrolyte, allowing for a more efficient transfer of energy. “The simple acid treatment can rejuvenate the surface of the PCEC, to help it achieve maximum performance,” said Wenjuan Bian, a postdoctoral fellow and primary contributor to this project. “This approach can be readily scaled up and integrated for large cell and stack manufacturing”

Upon close examination, researchers found that the acid treatment increased the area of contact between the electrode and electrolyte — roughing up the surface in much the same way that a potter would rough up the moist clay of a cup before attaching the handle.

The increased surface area caused a tighter bond between electrode and electrolyte that allowed for a more efficient flow of hydrogen atoms. Additionally, the cell stability improved significantly, especially under certain extreme conditions.

This process could open the doors for numerous “clean and green hydrogen” applications, Wu said.

“The high performing PCEC allows us to push operating temperature down to 350 C,” Ding said. “Reduced operating temperature enables cheaper materials for the large-scale assembly, including the stack. More importantly, the technology operates within the same temperature range as several important, current industrial processes, including ammonia production and CO2 reduction. Matching these temperatures will expedite the technology’s adoption within the existing industry. In fact we are accelerating the scale-up of these cells at INL, by integrating this technology into our manufacturing processes.”

For more information, see the publication here.