Idaho lab completes bench testing for electric vehicle wireless charging

Editor’s Note: A bio of researcher Richard “Barney” Carlson is available here.

Idaho National Laboratory researchers and six companies have achieved a major milestone by completing bench testing for wireless charging systems, a technology that eliminates the need to plug in electric vehicles.

INL researchers collaborated with Toyota, Nissan, WiTricity, Jaguar Land Rover, Qualcomm and one other auto company to perform the tests in the summer and fall of 2016. INL reported the test results to SAE International (formerly known as the Society of Automotive Engineers) in November 2016 to support the SAE Technical Information Report J2954™, a wireless charging guideline published earlier this year.

Wireless charging systems use electricity from the grid to generate a magnetic field from a charging pad on the ground that transfers energy to a pad under the electric vehicle. The energy is converted to electricity to charge the battery.

The SAE Technical Information Report J2954™ guideline is designed to allow charging pads from one company to work with the vehicle pads from another company. This “interoperability” is important for safety and performance of wireless charging systems.

“Electric vehicles equipped with a J2954 wireless charger should be able to charge over any J2954 charging pad,” said Richard “Barney” Carlson, an INL engineer who heads up the wireless charging tests.

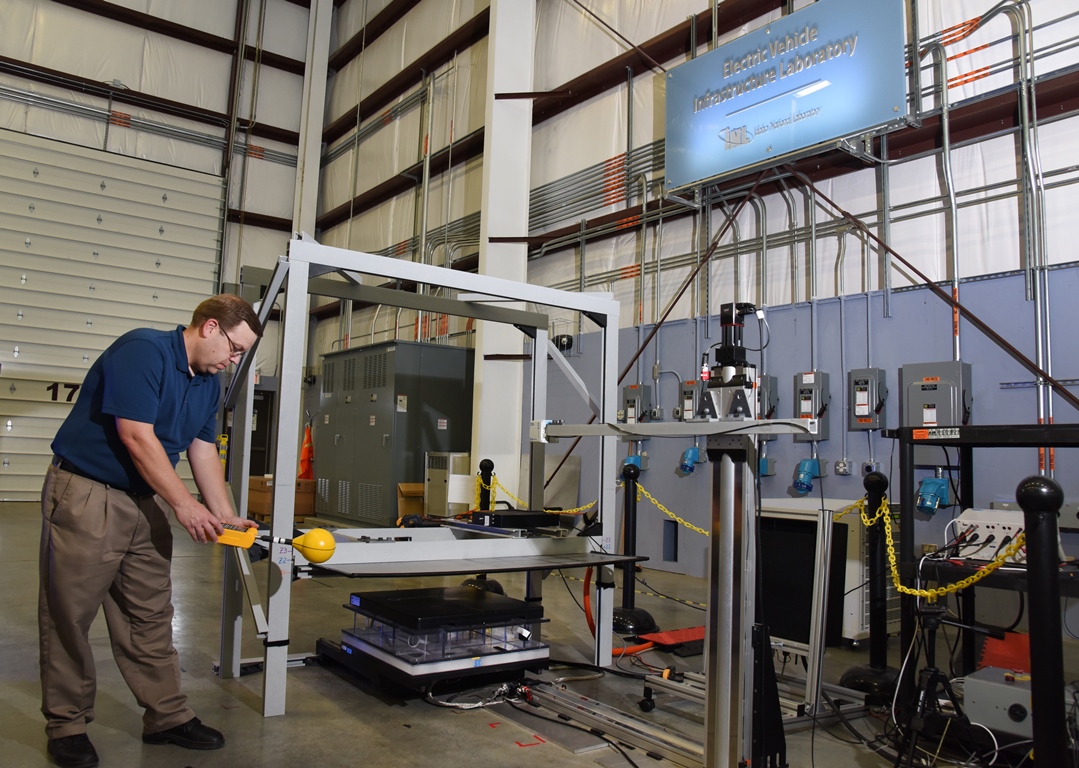

When it comes to wireless charging, the relative position with the ground pad matters. If the gap is too large, or the pads are misaligned, the charging efficiency is significantly reduced. At INL’s Electric Vehicle Infrastructure Laboratory, Carlson and his colleagues have developed a testing system to measure the efficiency of and electromagnetic field around the wireless charging systems.

A computer controlled motor driven table can precisely misalign the ground assembly relative to the vehicle assembly to determine how much energy is lost to the environment when cars aren’t perfectly parked. Then, different types of equipment are used to measure factors such as electromagnetic field strength, electrical power quality and charge power efficiency.

“This is the most comprehensive testing of its kind and will help the SAE committee develop the wireless charging guidelines,” Carlson said.

Engineers from the six companies visited the laboratory to collaborate on a series of interoperability tests for their respective wireless charging systems. The tests allowed those engineers to adjust their company’s systems in real time to improve interoperability performance.

Data from those tests will be used to further develop the draft SAE guidelines, which will ensure that wireless charging systems entering the market meet minimum interoperability requirements for proper functionality, high efficiency and safe operation.

“Idaho National Laboratory has provided SAE with invaluable bench data that the Technical Committee will use to develop the next phase of standardization, Recommended Practice SAE J2954™,” said Jesse Schneider (BMW), chair of the SAE task force. “Wireless power transfer vehicle data is needed before guidelines can be published. INL offers an ideal combination of expertise and capabilities to assist industry with this effort.”

In addition to the convenience of hands-free charging, wireless charging systems could provide fail-safe vehicle charging for drivers who might otherwise forget to plug in their cars. Such an oversight might have serious consequences for electric vehicle drivers because it takes more time for electric vehicles to charge than it takes to fill up the fuel tank of a conventional vehicle.

Funding for INL’s wireless charging testing in support of SAE International comes from the Department of Energy’s Vehicle Technologies Office.