R&D Impacts

FY22

Research to change the world’s energy future

INL’s strategic science and technology initiatives will help America achieve a low-carbon energy future that fully realizes the potential of nuclear energy. Future energy systems require innovations in advanced materials and cyber-physical infrastructure that is both resilient and secure.

Accomplishments and data are from fiscal year 2022.

In Lab’s History

FY 2022

Since 2005

Nuclear Energy Impacts

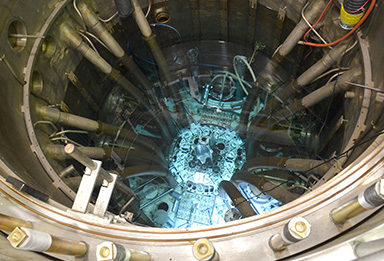

Overhauling ATR core internals

Workers at INL’s Advanced Test Reactor completed an 11-month outage for a core overhaul that occurs about every 10 years to maintain peak performance. During the overhaul, operators and maintenance teams replaced components that wear out over time — akin to rebuilding the engine of a high-performance car. ATR is the world’s largest, most powerful and flexible materials test reactor. The new core components allow ATR’s research missions to continue for another decade or more.

Taking nuclear power to the moon

INL and NASA selected proposals to design a fission surface power system for lunar applications. The project is sponsored by NASA to demonstrate a 40-kilowatt-electric nuclear reactor on the moon by the end of the decade. INL led the evaluation and awarded 12-month contracts to three companies for the Phase 1 design effort.

Net-zero national labs effort

INL and three other national laboratories are leading the nation to net-zero carbon emissions by demonstrating clean energy solutions. These four Department of Energy labs were selected as pilot laboratories because they conduct advanced energy research that can help the nation meet its decarbonization commitments.

Making fuel recycling a reality

A new collaboration between Idaho National Laboratory and the University of Utah aims to address nuclear waste challenges by making fuel recycling a reality for advanced reactors. The innovative zone refining technique, based on early nuclear research, won funding from the prestigious Advanced Research Projects Agency – Energy in March.

Plant automation tool improves safety, costs

Every issue in the nuclear industry, no matter how small, is documented in a condition report. In each plant, hundreds of these are reviewed and characterized every week by dozens of people. A technology named MIRACLE uses machine learning and natural language processing to automate this process, saving millions while improving safety. The methods developed in its creation could be valuable in any industry that requires massive volumes of documentation reviews.

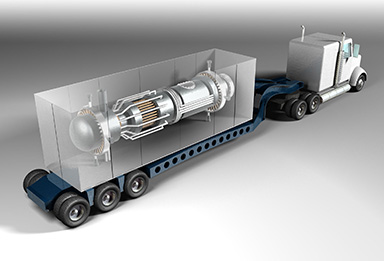

Analyzing global market for microreactors

Microreactors are small nuclear reactors that produce up to 20 megawatts of electricity or equivalent amounts of heat. They were initially designed for small applications outside a centralized electric grid, such as remote communities and military bases. Most designs would be built in a factory and shipped in cargo containers to locations around the globe. The INL report, Global Market Analysis of Microreactors, identifies potential markets for microreactors in 63 countries and assesses their commercialization potential between 2030 and 2050.

Initiating fast-spectrum salt reactor experiment

Southern Company and the U.S. Department of Energy established a cooperative agreement to design, construct and operate the Molten Chloride Reactor Experiment – the world’s first critical fast-spectrum salt reactor. The Molten Chloride Reactor Experiment will provide crucial operational data for fast-spectrum salt reactors and unlock this uniquely flexible advanced reactor technology for use in a net-zero future.

National Security Impacts

5G Wireless Test Range opens

The nation’s first open-air, 5G wireless test range focused exclusively on security testing, training and technology development opened at the U.S. Department of Energy’s 890-square mile INL Site. Although limited 5G service is available in selected cities across the country, widespread adoption is years away. Idaho’s Wireless Test Range will help researchers resolve security vulnerabilities and experiment with new capabilities made possible by 5G cellular technology.

Enhanced electric power grid opens

INL opened one of the nation’s most comprehensive electric power grid test beds this year. The full-scale test grid allows experts from across the federal government and private industry to develop and demonstrate technologies that improve security and enhance resiliency. Located across the INL Site, the test grid includes up to 32 miles of reconfigurable distribution line, 16 miles of transmission line, full fiber-optic communications and transformers capable of supporting demonstrations at 15, 25 and 35 kilovolts.

Protecting the power grid

In December 2022, a shooting attack on two electrical substations in North Carolina rang familiar to INL researchers. Nearly 10 years before, a sniper attack on a Northern California substation led them to develop a novel protective solution. The lab’s Armored Transformer Barrier system now has been licensed for production by Michigan-based Waltonen Engineering. Made from inexpensive yet rugged military grade steel, the armor package creates a formidable barricade to protect high-valued, critical substations from threats.

Preventing industrial cyberattacks

MOSAICS is a technology that provides the first comprehensive, integrated and automated solution to detect and prevent cyberattacks of industrial control systems. INL developed the MOSAICS technology with Johns Hopkins University Applied Physics Laboratory along with Sandia National Laboratories and Pacific Northwest National Laboratory.

Energy & Materials Solutions Impacts

Recycling lithium batteries

One of our world’s biggest clean energy challenges is recycling lithium-ion batteries. The EC-Leach technology unlocks the green energy potential of these batteries at the end of their lives by extracting and recovering critical materials. EC-Leach provides an answer to many complicated challenges yet requires no expensive or hazardous materials, has a low operational cost, and is compatible with any lithium-ion battery chemistry.

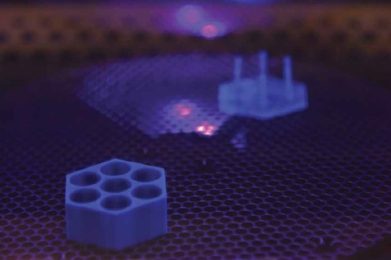

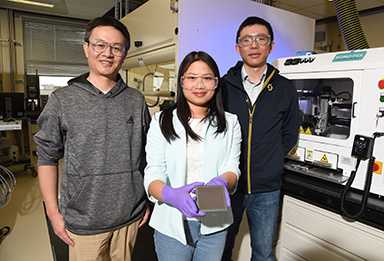

Modernizing advanced manufacturing

INL unveiled first-of-its-kind electric field assisted sintering technology in the form of the world’s largest direct current sintering equipment. The DCS-800 will allow for more efficient manufacturing, at industrial-length scales, of metals and ceramics using a process that produces lower carbon emissions. The manufactured materials are designed to withstand extreme conditions. Such materials must meet exacting specifications for use in technologies such as wind turbines, spacecraft, nuclear energy, protective systems and hydrogen cells.

Replacing diesel generators in remote communities

Many communities aren’t connected to a regional electrical grid, forcing them to rely on importing diesel fuel to meet their energy needs. A collaborative project between INL researchers, the Alaska Center for Energy and Power, and XENDEE Corporation is looking at the feasibility of enabling microgrids to integrate power from tidal or wave energy sources along with other renewables and energy storage.

Improving green tech efficiency

More efficient electrochemical cells could have numerous benefits. They could improve carbon-free hydrogen and chemical production along with large-scale electricity generation and storage. But first, scientists must overcome several challenges, including how to make the cells more efficient and cost-effective. A research team led by INL used a simple process to bind materials more tightly within protonic ceramic electrochemical cells, solving a mystery that had limited the technology’s performance.

Recycling solutions for remote locations

The U.S. Defense Advanced Research Projects Agency enlisted INL to help create a mechanical system that soldiers can use to separate their garbage and turn it into everything they need to survive: food and water for their bodies, fuel and lubricants for their vehicles. Before anything can be done with garbage, however, it must be cleaned and sorted, with organic (i.e., carbon-bearing) material separated from the inorganic.

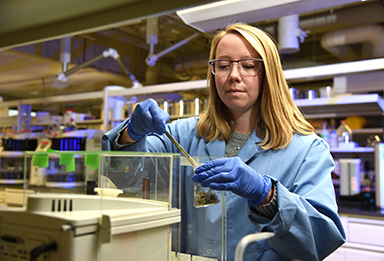

How garbage is becoming a bioenergy champion

An INL bioenergy researcher is leading new research that supports the Department of Energy’s efforts to decontaminate municipal solid waste, specifically for use as biofuels. Municipal solid waste is garbage thrown away in places such as homes, schools and businesses. It can include paper, plastic, food, clothing, and construction or demolition waste.

Previous R&D Impacts

2020 R&D Impacts

2019 R&D Impacts

2018 R&D Impacts

2017 R&D Impacts

2016 R&D Impacts

2015 R&D Impacts

2014 R&D Impacts

2013 R&D Impacts

2012 R&D Impacts

Not finding what you are looking for? Please send your question to [email protected].