Father and son entrepreneurs Mehul and Milan Shah have patented a new nuclear fuel design that could reduce nuclear waste, enhance safety and lower costs for today’s pressurized heavy water reactors.

The Shahs — CEO and chief operating officer, respectively, of Clean Core Thorium Energy, along with chief technology officer Paul Chan — combined thorium with high-assay low enriched uranium, which is enriched to between 5% and 20%. Typically, uranium in pressurized heavy-water reactor fuel is not enriched, meaning the fissionable uranium-235 element makes up less than 0.72% of the total.

“Our eureka moment came when we successfully developed a proliferation-resistant fuel design using thorium and high-assay low enriched uranium without requiring any modifications to the reactor or fuel bundle external geometry,” Mehul Shah said.

Called Advanced Nuclear Energy for Enriched Life (ANEEL), the Shah’s fuel design could operate in pressurized heavy-water reactors worldwide.

But before ANEEL fuel can enter the marketplace, the Shahs must prove its performance and safety to industry and regulators.

Unparalleled capabilities and expertise

After a few years searching for the right research facility, the Shahs connected with researchers at the Idaho National Laboratory (INL), one of the few places in the world with the expertise and capabilities to properly qualify their design at an accelerated rate.

INL and other national laboratories make their resources available to private companies to foster innovation in the energy industry. Without national laboratories, private companies could not create these essential capabilities on their own. This is especially true for the nuclear industry, and Clean Core is just one of many companies INL supports in nuclear fuel development.

In particular, the Shahs wanted the high neutron flux and high burnup offered by INL’s Advanced Test Reactor (ATR) and the “crash test” capabilities offered by the Transient Test Reactor.

“Those things aren’t found anywhere else in the world,” Mehul Shah said. “ATR is the Holy Grail for nuclear testing. Qualifying our fuel for testing there is like securing a seat on the only flight to the moon.”

In spring of 2024, ATR engineers placed 216 ANEEL fuel pellets in ATR’s special clover leaf-shaped reactor core. After four months of irradiation time, the first batch of fuel pellets is ready for examination. The remaining pellets will stay in ATR through spring of 2026 so researchers can study how higher burnup affects the fuel.

For the Shahs, this is the moment of truth. The data gathered through the efforts of INL experts will help prove the ANEEL concept for regulators and investors.

A national lab, university and private collaboration

Post-irradiation examination of the ANEEL fuel marks the culmination of a years-long collaboration among INL, Clean Core and Texas A&M University. While most private companies conducting nuclear fuel research receive some kind of government funding to help pay for their projects at INL, Clean Core’s irradiation testing at ATR is all privately funded.

INL sent uranium oxide to Texas A&M researchers, who mixed it with commercially sourced thorium oxide in a proprietary blend and fabricated the fuel pellets under INL’s Quality Assurance program. Unlike conventional fuel pellets, the ANEEL fuel is annular, which means it’s fabricated with a hole in the center of the pellet to better accommodate fission gas release at high burnup. The fuel pellets were then sent back to INL for quality control, assembly into the fuel capsule and insertion into ATR.

“The quality control was an adventure in itself,” said Michael Worrall, an INL researcher and principal investigator for the Clean Core irradiation experiment. “We measured them all, weighed them all, then sent several samples to MFC (INL’s Materials and Fuels Complex) to be dissolved. Thorium oxide doesn’t dissolve the same way uranium oxide does, but at the end of the day, the analytical lab got it done. They did mass spectrometry to make sure Texas A&M blended the pellets correctly. Under the leadership of Dr. Sean McDeavitt, the Texas A&M team nailed it. Everything was in spec. They did really well.”

Researchers divided the 216 fuel pellets that Texas A&M made for the ATR experiments into 12 capsules. They then divided the capsules into three “baskets” for insertion into the ATR core. The 12 capsules have different blends of uranium and thorium, including one capsule with pure uranium oxide as a control.

Each basket undergoes a different level of burnup — the amount of time spent being bombarded with neutrons in the ATR reactor core. The first basket was removed from the core in November 2024, achieving a fuel burnup of up to 25 gigawatt days per ton. After four months in ATR’s cooling pool and shipment from ATR to MFC, the fuel was ready for examination by mid-March 2025.

Post irradiation examination

Like similar fuel irradiation efforts for private companies, Clean Core’s post-irradiation examination starts at the Hot Fuels Examination Facility, the nation’s largest and best-equipped hot cell for processing and examining irradiated nuclear materials and fuels.

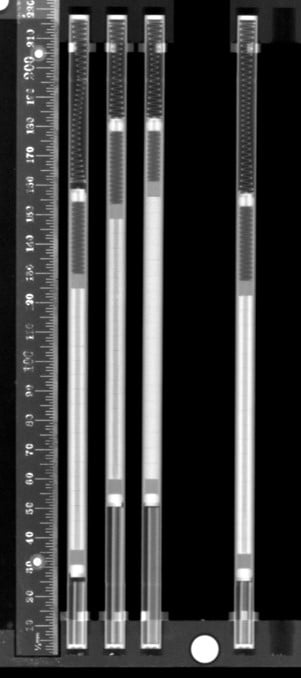

After arrival at the facility, one step in the post-irradiation examination process is to perform neutron radiography on the fuel to evaluate the fuel’s physical changes during irradiation.

Figure 1 shows the capsules after irradiation in ATR. These initial images reveal no obvious cracks in the fuel, no collapse of the annular fuel form and no gross deformation of the rodlet.

These early results indicate good structural integrity and irradiation stability for Clean Core’s ANEEL fuel. “The irradiated pellets look exactly like when they were fabricated,” said Chan. “This is important news for the fuel community. This is great.”

Following radiography, the fuel will undergo several more non-destructive exams, including a visual examination; profilometry, which measures the rod’s surface looking for physical dimensional changes; and detailed gamma scanning, which looks for fission-product distribution in the fuel. Finally, the fuel rodlets will be disassembled so the fuel pellets can be inspected. Because the fuel rodlets must be cut open to access the fuel pellets, these types of exams are known as destructive examinations. Destructive examinations will include collecting fission gasses within the fuel pin and using microscopy on individual fuel pellets to examine the effect that irradiation has on the fuel’s microstructure.

“We’ll be looking at the grain growth and the grain structure to see how it behaved,” said INL experiment manager Ethan Oberg, who will lead the post-irradiation examination of the Clean Core fuels. “We will also examine the fuel’s porosity and fission products distribution.”

Establishing U.S. leadership

These collaborations between private companies and INL help industry power the reactors of the future. “One of our major goals is helping create nuclear leadership and, in our case fuel leadership, in America,” Milan Shah said.

INL plays an essential role in meeting these goals. Combined, the lab’s one-of-a-kind manufacturing, irradiation and post-irradiation examination capabilities mean companies can prove their fuels with confidence in the resulting data. “This fuel has really embarked on a journey that would not be possible without the experts and capabilities found at INL,” Mehul Shah said.