Idaho tests help new technology ‘wow’ billionaire investors

When local small businessman and entrepreneur Mark Melni designed a new way to make repairs to broken underground electric lines that was more than six times faster than existing methods, he was pretty sure he had an industry-changing invention on his hands. In normal situations, restoring power that much faster is just good business, and in hazardous environments, a sixfold increase in repair times could literally be lifesaving.

But before his electrical coupler could be certified for use, he had to put it to the test – literally. Unable to find a private facility that could safely provide the voltage he’d need to test his invention, he turned to Idaho National Laboratory and its Technical Assistance Program. TAP is a support program authorized by federal law to provide access to scientific and engineering expertise for small businesses.

“The TAP program provides up to 40 hours of technical assistance to small technology-based businesses in the areas of nuclear energy, other energy solutions or national security,” said Stephanie Cook, wholeads INL’s technology-based economic development activities. “Our research team really enjoys working with the six to nine small businesses that participate in TAP every year.”

As Melni discovered firsthand, the program is particularly beneficial to organizations that find their problems too complex or technical to solve on their own. “The Technical Assistance Program helps entrepreneurs like me get help we couldn’t get anywhere else,” he said.

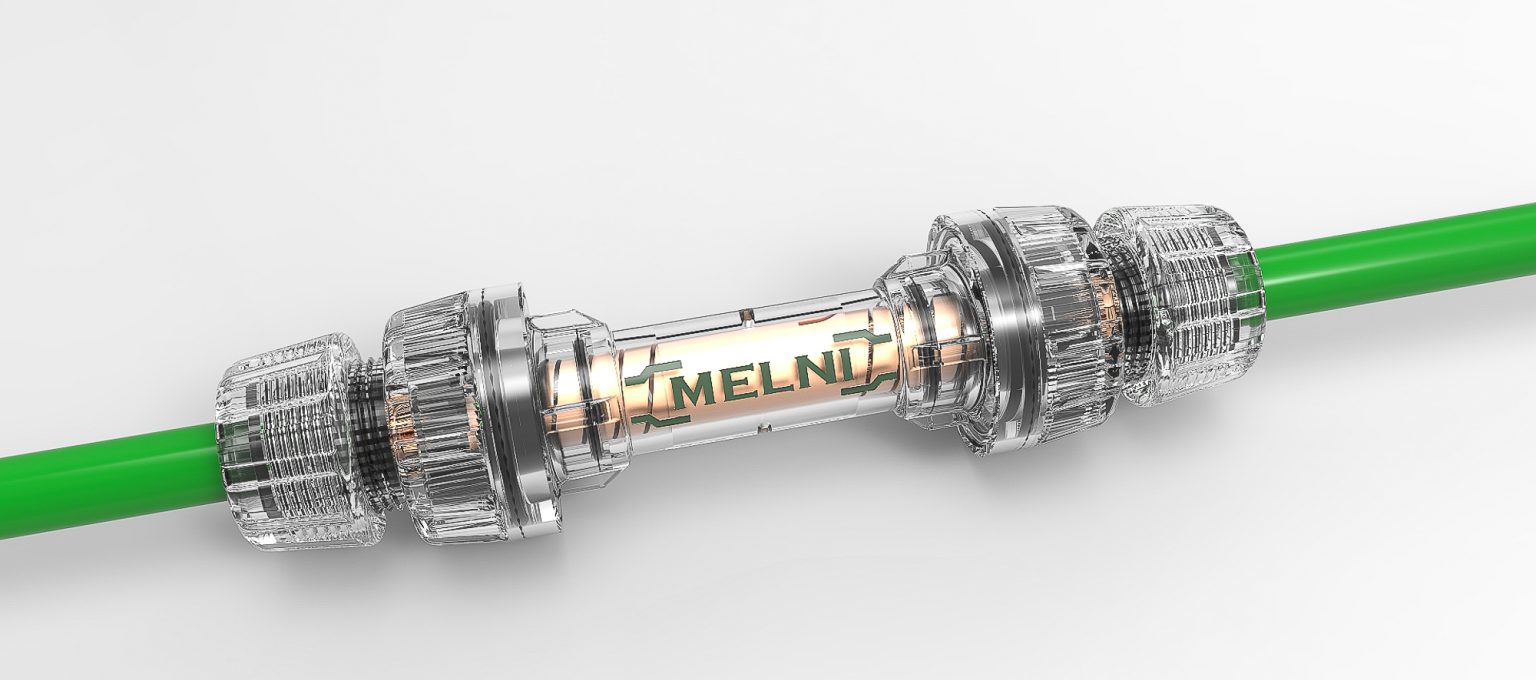

INL’s Technical Assistance Program helped entrepreneur Mark Melni test the electrical coupler he developed.

Having been in his family’s computer repair business for 20 years, Melni was well-acquainted with the traditional method of connecting two electrical wires together in a smooth inline splice: the so-called butt splice. Insert two loose wires stripped of insulation into either end of a plastic-wrapped copper tube and squeeze with a crimping tool until the tube has been squished down on the loose wires, forming a secure electrical connection.

The process, familiar to any electrical hobbyist, is essentially the same one used to repair breaks in secondary electrical lines, the underground cabling between overhead power poles and residences. The cabling in use for these lines is much, much bigger than anything a hobbyist would use, though, necessitating some very specialized equipment to mend it.

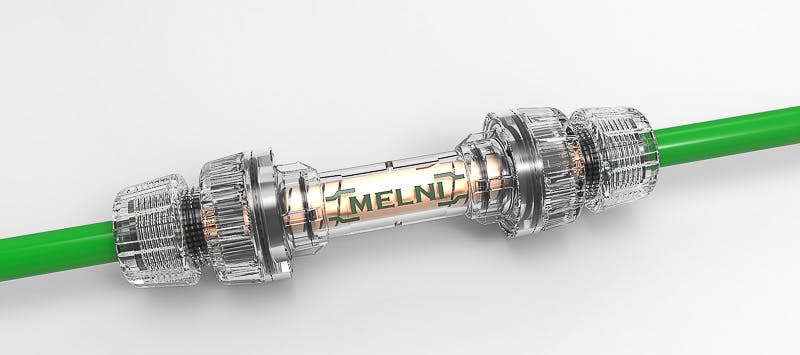

That equipment is heavy, cumbersome, and time-consuming to use, all problems Melni believes he has solved with his new type of connector. It does away with all the squeezing and crimping involved in a traditional splice and instead uses an electrically-conductive spiral that envelopes both ends of the wires to be spliced, essentially forming a high-tech Chinese finger trap: the harder the splice is pulled, the more snugly the mesh grips the ends of the wires. The entire connector is housed in an airtight and watertight canister, making the device ideal for underground use.

Melni aimed to simplify electrical splices for secondary power lines.

Melni’s relationship with INL started when he won an entrepreneur contest in 2010 that was sponsored in part by the lab. With his $10,000 award money, Melni set out making prototypes of his connectors and asked INL, via its Technical Assistance Program, to provide the specialized testing that he couldn’t readily find elsewhere.

INL’s Mark Hunter, an electrical foreman at the Materials & Fuels Complex, supervised the electrical tests, simulating what Underwriters Laboratory – the ubiquitous UL found stamped on all electrical devices in this country – would subject the connectors to before granting their certification. “My impression is that it’s a pretty danged good idea,” said Hunter. “Voltage and amperagewise, [the connectors] exceeded anything I expected.”

Needing only to transmit 3,400 volts to be considered successful, Melni’s connector withstood a whopping 41,000 volts in INL’s test rig before failing. “It put us in a whole different category for voltage,” Melni said. Subsequent tests did nothing but reinforce that his connectors were up to whatever challenge could be thrown at them. Needing to withstand 450 pounds of pulling tension to be certified, the connector withstood 1,060 pounds of force before failing; needing to conduct 360 amps without heating by more than 122 degrees, the connector got only 80 degrees hotter. Submersion tests, impact tests – Melni’s invention passed them all with flying colors.

The testing process was one that Melni thoroughly enjoyed. “I hesitate to use the word ‘fun’ because it sounds adolescent, but I had so much fun! The guys at INL were great – it was so cool.” It’s a sentiment shared by INL’s electrical foreman on the project. “It was neat to see a new invention and feel like we were part of it,” said Hunter. “Normally, we’re going in and fixing something broken; we don’t usually get to run something to failure. Fun? Yeah, testing was fun!”

That extensive testing – and maybe a bit of the fun – recently paid off: Melni successfully pitched his connectors on ABC’s “Shark Tank,” a reality show that assembles a group of billionaire investors to hear out the grand ideas of hopeful inventors. So impressed was one investor, Mark Cuban (yes, the owner of the Dallas Mavericks) by the advantages Melni’s connectors hold over traditional splicing techniques that he offered up a $500,000 investment in exchange for a 12 percent stake in the company.

While Melni appreciated the investment – and the subsequent increase of his company’s online presence and sales orders after the episode aired – he well knows that the success of his invention rests upon sound science and rigorous testing – INL hallmarks. “INL is one of the best things to happen to our company; it was monumental,” Melni said. “Without the lab’s help, we would not be anywhere near where we are today.”