Drinking water warnings and “keep out” orders are just a symptom of the rapidly growing algae bloom crisis affecting lakes and sources of fresh water in the U.S. and around the world. The solution to this growing environmental crisis may come from an unlikely combination of an Idaho Falls entrepreneur’s invention and an INL nuclear waste treatment technology.

The root of the problem is phosphates. Great for crops, but in excessive amounts, bad for your local drinking water source or swimming hole, and potentially disastrous for the towns and businesses that depend on these sources for clean water. So far, the problem has affected thousands of lakes and other freshwater sources, with losses totaling well into the billions of dollars, and the costs continue to mount.

Phosphates, another name for phosphorus-containing compounds, are a key ingredient in many crop fertilizers. Runoff from farms can make its way to lakes and slow-moving streams, and when temperatures rise, explosions in the population of blue-green algae can result, forming a gooey green sludge. The so-called algae are not actually algae at all, but a type of bacteria that release toxins as they break down.

Idaho Falls-based Rocky Mountain Scientific Inc. (RMS) has been working on the phosphate problem for the past couple of years. In their work, they discovered a compound that removes phosphates from water extremely well.

“We knew our compound had enormous potential for solving the algae bloom problem that is spreading to more and more water sources around the world,” said Steve Hammon, CEO of Rocky Mountain Scientific Inc., who along with RMS Chief Technology Officer Mike Irish developed the phosphate-attracting compound. “We had a problem, though. On its own, the powder form of our compound would either gum up equipment or be quickly carried away by water flowing through the system. We needed something to hold it in place.”

Hammon knew of INL’s expertise in nuclear and chemical separations research and in developing treatment technologies for nuclear wastes, so he sought help from the Aqueous Separations & Radiochemistry department in INL’s Nuclear Science & Technology division. Small technology businesses like RMS are eligible to apply for help through INL’s Technical Assistance Program (TAP). Through TAP, Hammon was able to take advantage of forty hours of free support to engage with INL researchers and lab capabilities.

Upon hearing about the challenge RMS was facing, INL research scientists Troy Garn and Mitch Greenhalgh suggested a composite approach that has been successful in solving treatment challenges at INL facilities. Garn and Greenhalgh are inventors, along with Jack Law, manager of INL’s Aqueous Separations and Radiochemistry department, on a patent for a process to create composite pellets that incorporates a binder with the active ingredients that can remove specific target elements from liquid or gaseous waste streams.

“At INL, we’ve had several successes in the past with combining our composite material with different active ingredients to target specific components,” Garn said. “We’ve studied it to remove cesium from radioactive and acidic waste streams, and most recently, for selectively removing noble gases such as krypton and xenon from off-gas treatment systems, just to name a few. There was no reason to think we couldn’t make it work with RMS’s amazing active ingredient to target phosphates, too.”

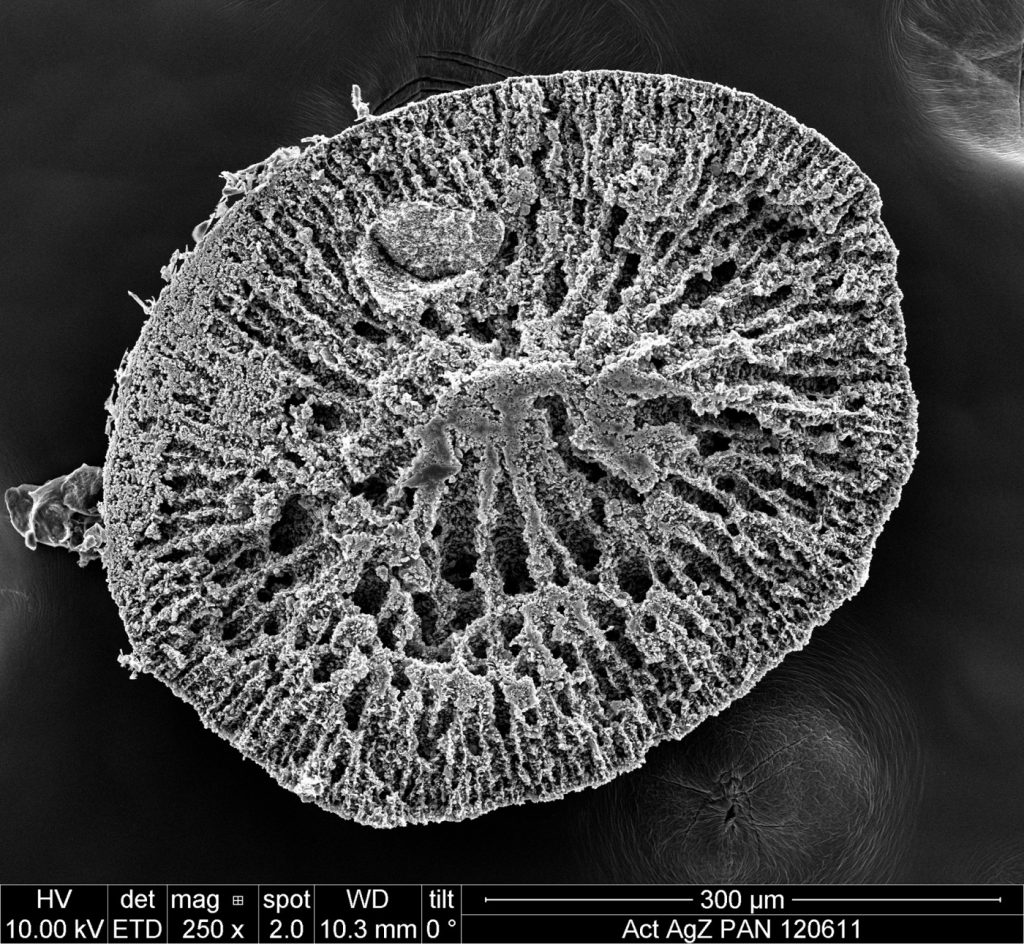

An initial test in RMS’s Idaho Falls lab was conducted to confirm that making a composite material using INL’s binder and RMS’s active ingredient was feasible. The binding process was successful. Next, a simple, cobbled-together series of interconnected containers holding beads of the new composite – named Phosphate Sponge – was assembled to test phosphate capture on a larger scale. Further tests included filling small filters with the material and put them in household fish tanks, and in both cases, the phosphates in contaminated test sample batches are removed from the water, down to levels of just a few parts per billion, if it’s even detectable at all. The result: crystal clear, phosphate-free water in which the blue-green “algae” bacteria can’t grow. As an added bonus, the phosphates can be eluted from the composite beads (removed in a process similar to that used for water softeners) and recycled as a fertilizer feedstock, and the beads themselves can be reused hundreds of times.

“It’s exciting to think about the potential for this composite, given the rapid spread of the algae bloom problem around the country,” Greenhalgh said. “We can greatly reduce the impact of phosphates on our bodies of water, and at the same time we can reuse the composite filter beads, and potentially recycle the phosphates back into fertilizer. As far as ‘green’ products go, I think working with RMS has been a grand slam.”

RMS worked with Gary Smith, a senior commercialization manager with INL Technology Deployment to receive an exclusive U.S. license to use INL’s patented technology to produce the Phosphate Sponge for removal of phosphates, arsenic, fluoride and selenium from water. “The binding technology INL developed has worked perfectly for our application, like it was made for it,” Hammon said. “We are extremely grateful for the help of INL’s inventors in developing the technology to make the composite product, and in our follow-up testing to refine the production process and the methods for recycling. Phosphates are an enormous environmental problem around the world, and I think we have a real solution with our product.”

Companies interested in the INL Technology Assistance Program can reach out to INL’s Partnerships organization at https://inl.gov/inl-initiatives/economic-and-workforce-development/

George Barley Water Prize

The algae bloom problem resulting from phosphate contamination has grown in recent years to such a degree that it is spawning environmental response efforts and even competitions aimed at encouraging the development of simple, inexpensive and innovative technologies to help solve it. One of these is the George Barley Water Prize, a multiphase innovation competition sponsored by the Florida Everglades Foundation and numerous environmental and corporate sponsors. RMS is involved in this effort and thus far has completed Stage 2 with very promising results, up against university research institutions and foreign government-sponsored teams all working on different treatment systems.