To understand Idaho National Laboratory’s long-term involvement in small modular reactor (SMR) research, including NuScale Power and the Carbon Free Power Project, one needs to go back to the late 1990s.

For most of that decade, the U.S. government had not offered much support for nuclear energy research and development. In Idaho, in 1994 the Integral Fast Reactor (IFR) project was cancelled and the Transient Reactor Test Facility was put on operational standby.

Nevertheless, when President Bill Clinton ordered his Committee of Advisors on Science and Technology in 1997 to review the national energy portfolio, Jim Lake saw an opening. Lake, the Advanced Nuclear Energy research and development director at Idaho National Engineering and Environmental Laboratory, joined with colleagues from other national labs and the American Nuclear Society to testify before the committee.

“It was a scary time, actually,” said Lake, now retired and living in Sun Valley, Idaho. “Except for a few fellowships, the budget for nuclear research had been reduced to zero.”

The committee listened, however, and Lake said he felt like nuclear got a fair hearing. In November 1997, one of the committee’s recommendations was for work on new reactor designs that could compete in the global market on the basis of higher efficiency, lower cost and improved safety. Another was for lower-output reactors for use in settings where large reactors are not attractive.

“When all was said and done, their report was pretty positive,” Lake said. With help from William Magwood IV, the Department of Energy’s director for nuclear energy under presidents Clinton and later George W. Bush, nuclear R&D money started reappearing in the DOE budget. In 1999, INEEL and Argonne were named as lead laboratories for nuclear reactor technology in the U.S. Department of Energy’s national laboratory complex.

It was DOE funds through the newly formed Nuclear Energy Research Initiative in 2000 that enabled a team from INEEL, Oregon State University (OSU) and Nexant (an energy and technology consulting subsidiary of Bechtel) to work on a three-year project called the Multi-Application Small Light Water Reactor (MASLWR). This was the seed from which NuScale’s Small Modular Reactor eventually sprang.

“There was a little bit of a groundswell of ‘Let’s bring nuclear back up,’” said Kevan Weaver, now INL’s technical lead for reactor systems safety. “For me, it was being in the right place at the right time.” Weaver, who’d come to INEEL in 1998, led the lab’s Advanced Reactor Design Group when he joined the project.

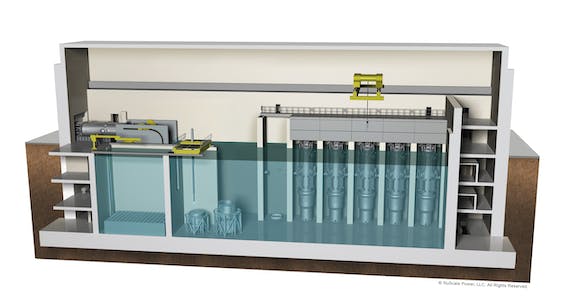

The team ended up designing a 45-megawatt unit, describing it as “a small, safe and economical natural circulation reactor.” Electric power generation would be the primary goal, but MASLWR was envisioned to also be adapted for “process heat” applications such as water desalination or district heating.

MASLWR’s funding ended in 2003. Weaver moved on to other projects. Meanwhile, OSU scientists led by MASLWR team member Jose Reyes continued to work on designing a small nuclear plant using natural circulation, eventually building a one-third scale electrically heated version as a test facility. In a 2007 technology transfer agreement, OSU conferred to NuScale Power the exclusive rights to the nuclear power plant design and continued use of the test facility.

Over the next several years, INL and NuScale’s paths diverged. In 2008 NuScale informed the U.S. Nuclear Regulatory Commission (NRC) it intended to pursue design certification for a 45 MWe module that could be operated either independently or as part of a multi-module facility. In 2011, Fluor Corporation became the company’s primary investor, bringing its global engineering, fabrication, procurement, and construction capabilities, along with global sources and established supply chain.

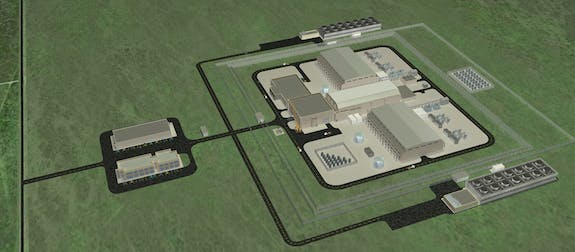

Also in 2013, the Western Governors Association released its “State of Energy in the West” report. One stated goal was to find ways to bring small modular reactors into western states. About the same time, NuScale announced the launch of the Western Initiative for Nuclear, a demonstration project in Idaho to be built and owned by Utah Associated Municipal Power Systems (UAMPS), a consortium of regional utilities, and operated by Energy Northwest.

Eastern Idaho was a logical place to site the project, said Mike McGough, NuScale’s chief commercial officer, who spoke to the Greater Idaho Falls Chamber of Commerce that September.

In December 2013, DOE announced it had selected NuScale to receive up to $226 million in matching funds to support further design development and to secure NRC design certification. Talks about possible locations at DOE’s 890-square-mile Idaho site then started in earnest – including discussions with state and local stakeholders, and with the Shoshone-Bannock Tribes.

“NuScale was the first entity to come in and say, ‘We’ll build it and we’ll make money with it,’” said George Griffith, INL’s SMR technical coordinator. While NuScale pursues licensing from NRC, Griffith’s job involves coordinating communication between the company, DOE and UAMPS.

Four alternate locations for the SMR Project were selected for further study.

“UAMPS wanted to site here, and the primary benefit of that, I believe, is INL knows what’s going on here,” Griffith said. “We’ve been operating reactors for more than 50 years. We know about the seismic conditions, we know about the water, we know about the environment.”

One of INL’s big contributions to NuScale was helping the company customize the RELAP5-3D code, a simulation tool developed at INL that allows users to evaluate how safe systems are in various situations. This helped speed up design certification application with NRC. INL’s expertise in fuel development and materials testing are a great asset, Griffith said. Following NuScale’s lead, other companies are approaching DOE about the possibility of siting their SMR demonstration projects in Idaho.

“DOE is adamant about wanting to be a fair host to anybody who comes in with questions,” Griffith said.

In January 2018 NRC announced its conclusion that NuScale’s novel safety design approach eliminates the need for class 1E power. Class 1E is the regulatory standard set for the design of safety-related nuclear power plant electrical systems, and all nuclear plants in the U.S. are required to have it. In its Safety Evaluation Report, however, the NRC approved NuScale’s “Safety Classification of Passive Nuclear Power Plant Electrical Systems” Licensing Topical Report, in which the company established how its design can be safe without reliance on any safety-related electrical power. The NRC has limited its approval solely to NuScale’s design.

This was a key milestone in the review process of NuScale’s Design Certification Application (DCA). Next steps include an NRC license application, NRC-led Environmental Impact Statement, and NRC license to build and operate the facility, to start generating carbon-free electricity for customers 24 hours a day, seven days a week.

If all goes according to plan, the plant is expected to be operational by the mid-2020s.

Weaver, who returned to INL from TerraPower earlier this year, said he would never have imagined in 2003 that NuScale would come into being much less be where it is now. “I never thought they would have said, ‘Let’s do the company ourselves,’” he said. Nor did he think the research he participated in would represent such a role in the revitalization of nuclear energy in the United States.

“It was a fun research project at the time,” he said. “More than anything, it’s refreshing to see NuScale is progressing well.”