In the spring of 2020, a team of engineers at the Idaho National Laboratory (INL) embarked on a groundbreaking project to design a microreactor test facility that could transform the world’s energy future.

At the center of it all was Carlo Parisi, who vividly recalls conceiving a critical mechanism for the cooling system of the Microreactor Applications Research Validation (MARVEL) project.

Five years later, the efforts of Parisi and his team have culminated in the latest successful three-month testing campaign using a one-of-a-kind Primary Coolant Apparatus Test (PCAT), a non-nuclear integrated test facility, allowing rigorous validation of the microreactor’s components, marking a milestone of innovation in the nuclear sector.

“Over Memorial Day weekend, I demonstrated through analytical modeling and numerical simulation that our cooling approach was feasible,” said Parisi. “I performed back-of-the-envelope calculations and ran detailed simulations to prove our design’s functionality and viability.”

“MARVEL has a unique combination of fuel, coolant and geometrical configuration that has never been used by any other reactor,” Parisi said. “It was crucial to create this mock-up for testing because there was nothing similar anywhere in the world for comparison.”

PCAT testing campaign

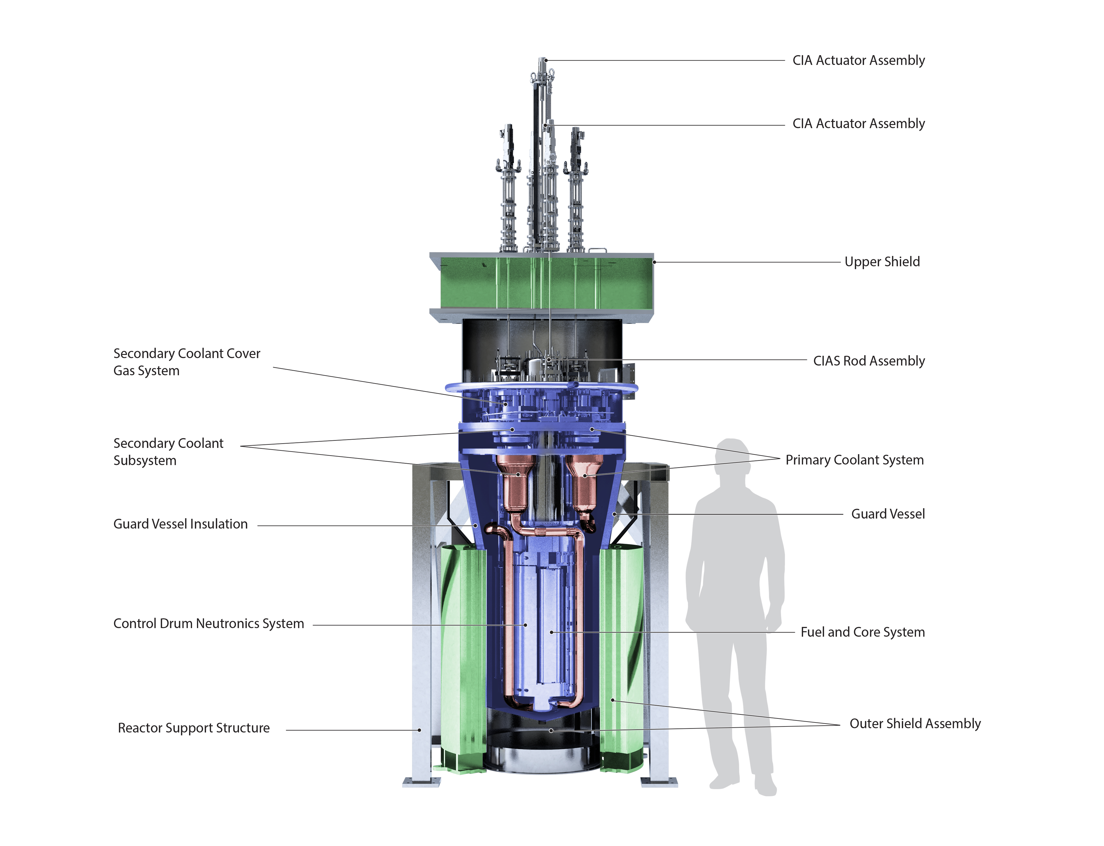

To put it simply, PCAT is an almost exact model of the primary coolant loop of the MARVEL reactor, designed to replicate its thermal hydraulic behavior using electricity instead of nuclear power to generate heat.

In a nuclear reactor, the primary loop acts like a vehicle’s radiator, circulating coolant to remove heat from the reactor core and transferring it to a secondary system, which may be used to generate process heat or electricity.

The PCAT replicates the MARVEL reactor’s primary loop, enabling engineers and researchers to conduct tests and experiments to evaluate the cooling system’s performance, safety and efficiency, and other components of the MARVEL microreactor before operating the actual reactor. This testing is essential for validating the design and ensuring the microreactor will function safely and effectively in real-world situations.

Unlike cars that use water pumps to circulate coolant and dissipate heat, MARVEL employs a natural circulation passive mechanism, which is akin to how hot air rises in a chimney when a fireplace is lit.

“So, the first objective of the PCAT testing campaign is to demonstrate that this natural circulation mechanism works properly, because if not, we could damage MARVEL’s nuclear fuel by overheating it,” Parisi said.

“The second important objective is to use the experimental data to check the accuracy of the predictions of RELAP5-3D, the INL software that we use for the thermal-hydraulic design and the safety analysis of MARVEL. It is very important to know our software is accurate in modeling the natural circulation for the peculiar geometry of MARVEL”

Initially, MARVEL faced challenges, including issues with the Stirling engines employed for heat removal. A Stirling engine uses external heat to expand and contract gas inside it, and the engine’s vibrations and noise levels raised concerns about the system’s reliability. In response, the team opted to redesign the tertiary cooling system, replacing the Stirling engine with a more stable radiator-like setup.

“That was a pivotal moment for us,” Parisi said. “We had to rethink our approach to ensure the system’s effectiveness and reliability.”

For cooling, MARVEL uses liquid metal, which can be difficult to handle and reacts to air and water. So, the INL engineers looked to Creative Engineers, a Pennsylvania company specializing in handling liquid metals. “Their expertise was crucial due to the challenges of working with the liquid metals used in MARVEL,” Parisi said.

Key findings and insights

The series of PCAT tests unveiled promising results for the MARVEL reactor. They confirmed that a stable natural circulation flow can be established to operate safely and allow MARVEL to generate as much as 100 kilowatts of thermal power.

“If the natural circulation mechanism works in PCAT, it is expected to work even better in MARVEL, thanks to its superior heat removal capacity,” Parisi said.

However, the tests also brought attention to an unexpected challenge. The PCAT system experienced greater heat losses than anticipated. “This is an important lesson for assembling MARVEL, as understanding and accounting for these heat losses will influence the reactor’s performance and efficiency. Heat losses are bad because they can decrease the reactor’s efficiency, similar to how poor insulation in a house can lead to higher heating costs,” Parisi said.

In another positive development, the experimental data gathered from PCAT closely matched the numerical predictions of the RELAP5-3D code, with deviations of just a few percentage points. This close alignment serves as a robust validation of the RELAP5-3D code’s accuracy and reliability in safety analyses.

“The more accurate the software is, the more we are confident in its predictions of operational and accidental events.” Parisi said.

Path forward for deployment

As the MARVEL project moves forward, the next steps will focus on fabrication, assembly and startup at INL’s Transient Reactor Test Facility.

“The results indicated that the level of conservatism built into the MARVEL evaluation was adequate,” MARVEL Microreactor Lead Abdalla Abou-Jaoude said. This allows the MARVEL team to proceed with preparing and submitting the safety documentation to (the Department of Energy) and moving the reactor on the path toward construction.

The team will analyze the large dataset collected from the PCAT experiments. Once the data-processing is complete, it will share the findings with the global scientific community.

“There is significant knowledge to be gained from these results,” said Parisi. “I do hope the MARVEL team’s work will contribute to advancing deployment of nuclear power.”

This progress is crucial as MARVEL exemplifies commitment to expanding nuclear energy production. By accelerating the testing, deployment and commercialization of microreactor technologies, the Department of Energy aims to innovate and achieve energy dominance for the United States.

“Knowing that we have accomplished something unique and groundbreaking is incredibly rewarding,” Parisi said. “We’ve created a system and a wealth of knowledge that will not only benefit our project but also potentially help the entire industry.”

Known for being compact, efficient and reliable, microreactors are ideal for remote and industrial applications.

“Microreactors have the potential to transform the energy landscape, offering a versatile and resilient solution for a wide range of applications,” said John Jackson, national technical director of the Department of Energy Microreactor Program. “This milestone brings us one step closer to realizing that potential.”