As our global need for sustainable fuel grows, bioenergy is one resource that holds the key to unlocking a cleaner, more renewable energy future. Idaho National Laboratory (INL) bioenergy researcher Rebecca Brown is leading new research that supports the Department of Energy’s efforts to decontaminate municipal solid waste, specifically for use as biofuels.

“The goal of the project I’m working on is to be able to use nonrecyclable waste to create biofuels, which are any fuel sources created from biomass, or organic matter,” Brown said. “Even though not all municipal solid waste comes directly from a plant-based organism, most of the fractions we are targeting are at least indirectly derived from organic matter.”

Municipal solid waste is garbage used and thrown away in places such as homes, schools and businesses. It can include paper, plastic, food, clothing, and construction or demolition waste.

Nonrecyclable waste includes items that are either too contaminated or expensive to recycle. Some of the most common contaminants are food products, such as grease left on a pizza box, or paper products that include other materials like metal or plastic, and other waste with inorganic contaminants including dirt from yard waste. Ink and adhesives on paper are also major contamination culprits. Adhesives can cause significant problems by gumming up machinery needed to convert the paper into a form usable for biofuels.

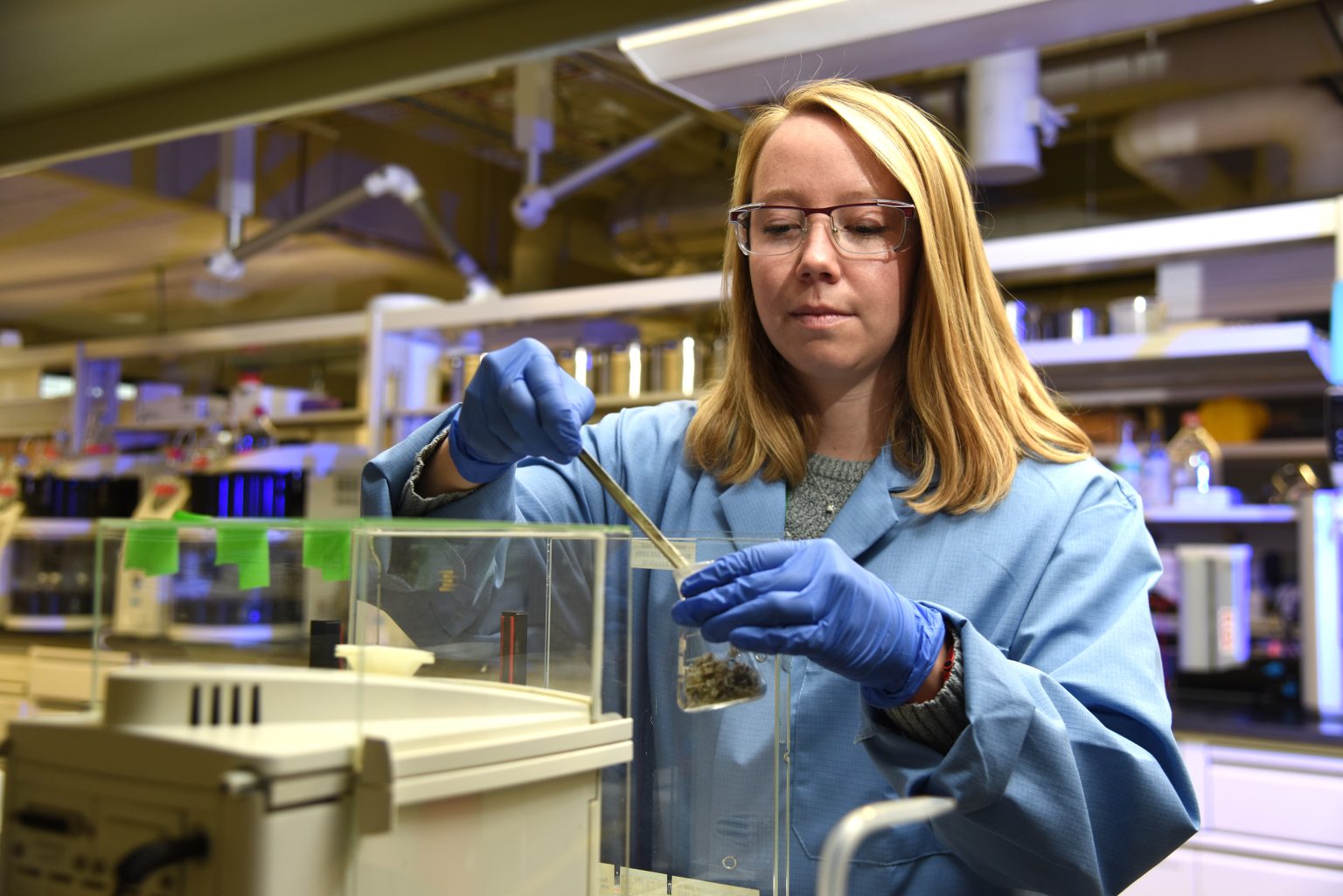

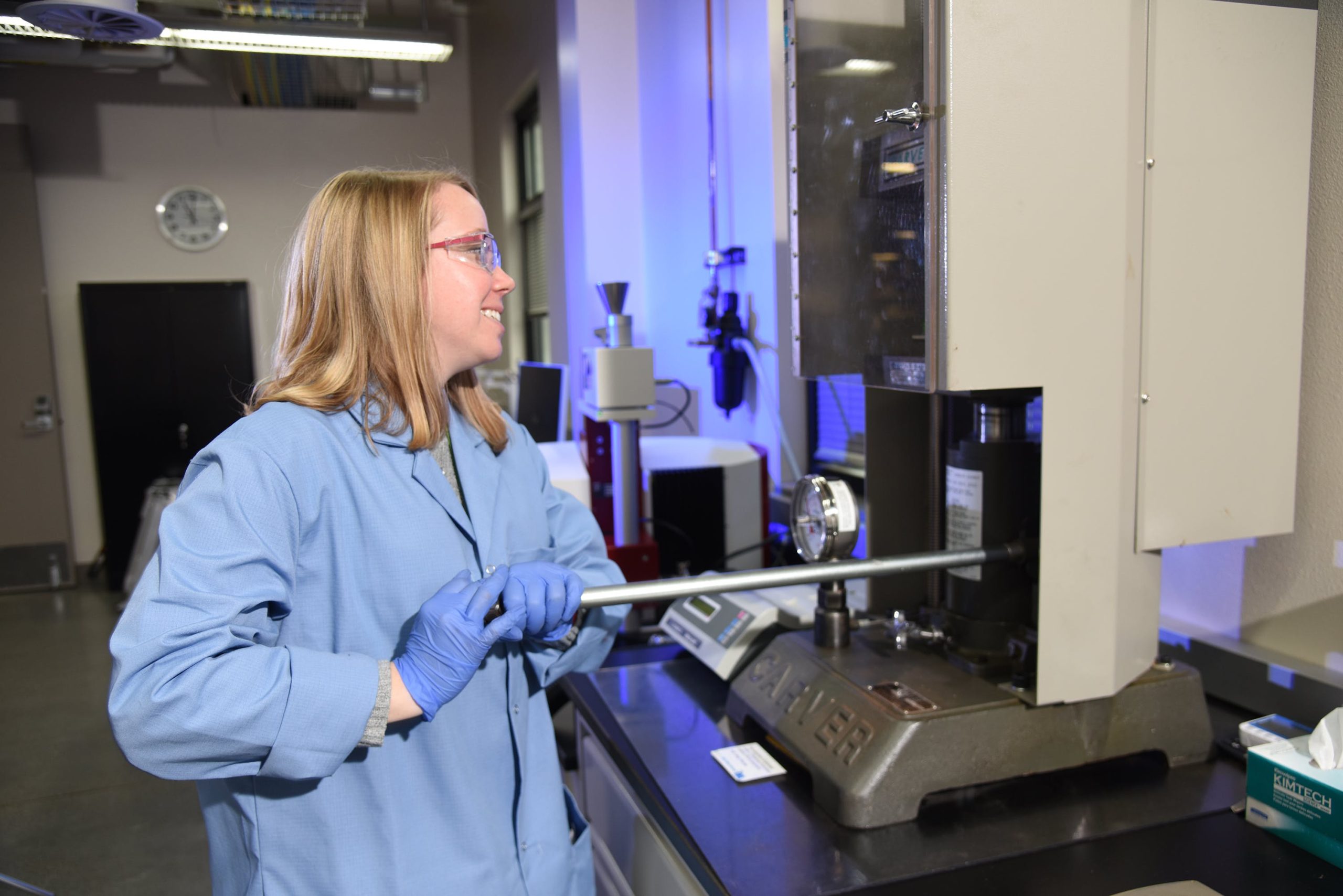

Brown is involved in research that characterizes the municipal solid waste fractions of plastic and paper to determine what contaminants might affect biofuel conversion. They then work to decontaminate them and increase the yield for fuel and product conversion.

“As part of this project, we’ve been using high temperature conversion, or pyrolysis, to convert plastic waste to liquid oil,” Brown said. The team used two different methods to clean plastic samples – a water wash and a dimethyl ether chemical wash. With both cleaning methods, the team was able to increase the yield of liquid oil products, which was a major success for converting the plastic portions of the nonrecyclable waste.

The team did not achieve this ultimate success without some frustration. Initially, Brown tested to see if sorting plastic contaminants from the paper portion increased their yield in biochemical conversion. It didn’t. When she compared the yield from paper contaminated with ink and adhesives versus paper with different, less problematic, contaminants, she still found no difference in biochemical yield.

At long last, however, she found a solution in the form of a dilute alkaline pretreatment. Biomass researchers commonly use this solution to alter the structure of agricultural biomass and make the cellulose more accessible to enzymes.

For Brown, this pretreatment method helped decontaminate some of the mixed paper products that came through the system.

The success they’ve had so far will provide integral support to biorefineries working to better decontaminate the paper product samples they receive.

The success of the project has earned additional funding from the Department of Energy’s Bioenergy Technologies Office. The main goal of this continued research is to find low-cost decontamination strategies, so the team can make municipal solid waste a more economically feasible raw ingredient for biofuel conversion.

“Right now, contaminated municipal waste is a bit of a negative value,” said Brown. “We can’t do much with it when it’s being put into a landfill. The average contamination rate of recyclables is 17%. If we can successfully decontaminate this waste and use it as fuel, its efficacy skyrockets beyond that of standard recyclable waste. Beyond that, if we can implement these strategies at biorefineries, our decontamination opportunities could become available on a national and even global scale.”